Results show improved nutrient digestibility, yields and profitability

The process used to produce aquaculture feeds has a direct impact on the physicochemical properties of the feeds, which can affect the durability and stability of the pellets and also the water quality. In addition, processing conditions during manufacture can also alter the nutritional quality of ingredients and thus influence feed digestibility and bioavailability.

Maintaining the nutritional quality of ingredients during processing is key in aquaculture feed manufacturing. The deterioration of nutritional quality and the misuse of nutrients are challenges in most traditional cooking methods used. Pelleting has historically been the most commonly used technique in the production of manufactured aquaculture feeds, but extrusion technology has some unique, favorable characteristics when compared to other cooking processes, since it is capable of transforming some nutrients (proteins, starches) so that its properties improve, increasing nutrient availability.

Additionally, the extrusion process denatures undesirable enzymes and deactivates some anti-nutritional factors, enhancing the bioavailability of ingredients. Precision in the bioavailability of a feed is relevant for the correct formulation and production of diets.

However, the success of extruded feeds depends on the machinery used and is also linked to knowledge and “expertise” in the process. Several years ago, industry consultant Charles Botting [Extrusion technology in aquaculture feed processing. 1991. American Soybean Association] illustrated the relevance of extruded feeds, stating, “Companies and clients often question the need to produce or consume extruded feeds, especially when they are achieving good results with pellets, but there is a great possibility to improve even more the quality and cost-efficiency of the product with extruded feed; a good extruded feed is always better than a good pelletized feed.”

This article, adapted from the original publication [Aquaculture (Ecuador) – Issue 134, April 2020], reports on the results of research to assess the effects of extruded feeds on their digestibility and production in Pacific white shrimp (Litopenaeus vannamei) juveniles.

Digestibility of proteins, amino acids and carbohydrates

In the first study, the apparent digestibility of protein (DAP), amino acids (DAAA) and carbohydrates (DAC) was determined in L. vannamei juveniles (6 to 10 grams) sourced from a local commercial farm with a salinity of 7.0 ± 0.4 ppt. The shrimp were acclimated to the salinity of the experimental unit and fed extruded and pelletized diets with the same base formula (35 percent crude protein, 7.5 percent crude fat), which included chromium oxide as an inert marker.

This experiment was carried out in a recirculation system using 60-liter tanks, and the water was recirculated at a daily rate of 400 percent. Ten shrimp were stocked per tank and maintained for five days before feces collection started. The animals were fed once in the morning and once in the afternoon, with a 3 percent daily increase in the feeding rate.

Extruded and pelletized diets were randomly assigned to each experimental tank in quadruplicate. At the beginning of each collection day, feces and uneaten food were removed from the tanks to minimize any undesirable effects that might be due to leaching. Fresh feces were collected after each feeding by siphoning, washed prevent any effects due to salinity, and stored refrigerated until being lyophilized for subsequent analyses.

Our analyses showed a statistically significant difference (p <0.05) in protein digestibility levels: the percentage of protein digested in the extruded feed was higher than in the pelletized feed. In other words, shrimp utilized better the protein of the extruded diet (Table 1).

Molina, extruded feed, Table 1

| Feed | DAP (%) | DAC (%) |

|---|

Feed | DAP (%) | DAC (%) |

|---|---|---|

| Extruded | 83.84 ± 0.67ᵃ | 93.88 ± 1.94ᵃ |

| Pelleted | 82.63 ± 0.93ᵇ | 90.71 ± 0.61ᵇ |

Proteins are essential components of the cell and therefore constitute the bulk of shrimp muscle tissue. Shrimp development is based on the release of essential amino acids to fulfill structural, regulatory and homeostatic functions. Research has shown that the heat treatment involved in the wet extrusion process used to make shrimp feed can be enough to inactivate most of the trypsin inhibitors [the enzyme trypsin is involved in the breakdown of many different proteins, primarily during digestion] in soybean meal. This is important, because trypsin is the protease in charge of breaking peptide bonds and releasing short-chain peptides and amino acids.

Amino acid digestibility in our results shows a significant difference in arginine, isoleucine, lysine, methionine, threonine, glycine and proline. In these cases, the digestibility percentage was higher for the extruded feed. And for the results for protein digestibility, the extruded product showed better bioavailability.

In addition, the percentage of amino acid digestibility in the extruded diet for lysine and methionine – two essential amino acids whose bioavailability in shrimp feed is of utmost importance for their metabolism and tissue formation based on complex proteins – is remarkable. This affects the formation of shrimp tissue and therefore the growth rate. A higher growth rate in turn allows greater efficiency and profitability, shortening the production cycle.

The most suitable energy sources for shrimp feeds are those ingredients with high carbohydrate content. But the starches from the vast majority of tubers, cereals and legumes that are used in animal diets are not easily accessible for the very important alpha-amylase enzyme, unless the grains are physically treated previously.

Wet cooking with temperatures higher than 70 degrees-C for several minutes is the main method that facilitates the availability of starch for water penetration and consequently allows the action of alpha-amylase. When starches are processed by extrusion, their structure changes radically, allowing more contact points for the enzyme to break down the starch into small molecules, releasing glucose. Therefore, cooked or gelatinized starches have higher digestibility compared to undercooked or raw starches.

Our results show that the content of digested carbohydrates in the extruded feed is significantly higher than in the pelleted feed (Table 1). The reason is that the extrusion cooking process of ingredients with high carbohydrate content increases their bioavailability, and therefore their assimilation.

Molina, extruded feed, Table 2

| Feed | Final weight | Weekly growth (g/week) | Biomass (g/tank) | FCR | Survival (%) |

|---|

Feed | Final weight | Weekly growth (g/week) | Biomass (g/tank) | FCR | Survival (%) |

|---|---|---|---|---|---|

| Extruded | 11.51a | 0.99a | 103.17a | 1.7a | 90a |

| Pelleted | 10.38b | 0.85b | 93.44b | 1.52a | 90a |

Performance under controlled conditions

In the second study, L. vannamei shrimp (3.86 ± 0.06 grams) were stocked at a density of 15 shrimp per square meter in tanks and reared for 54 days. The animals were fed two experimental diets, each with four replicate tanks per dietary treatment. The shrimp were slightly overfed three times a day so that feed availability was not limiting.

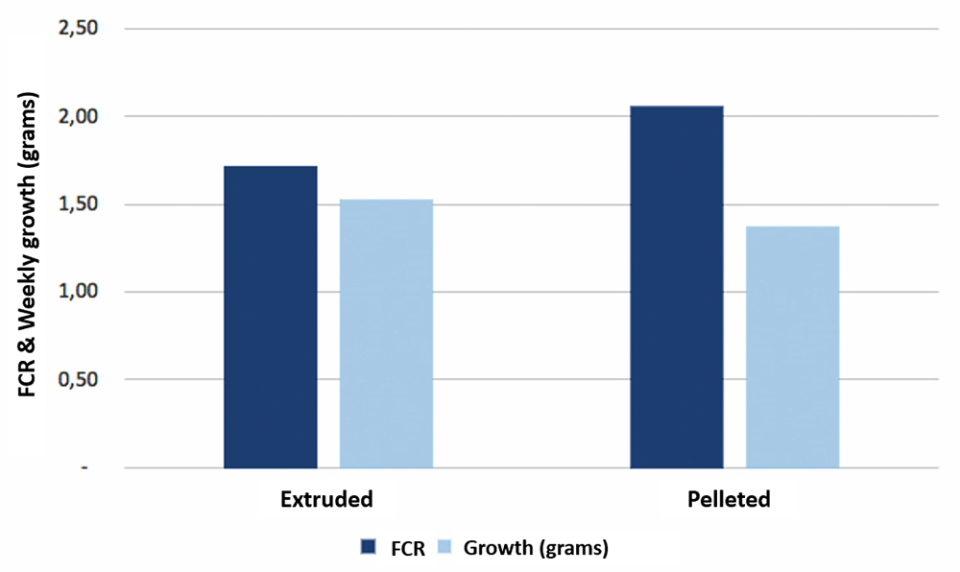

The results showed statistical differences (p <0.05) in weekly growth, weight and final biomass between the dietary treatments, while there were no differences for survival and feed conversion between treatments. The shrimp in tanks fed the extruded feed had 9 percent higher final biomass and 10 percent higher final weight, indicating that the extrusion process positively influences shrimp performance.

Previous studies with extruded feeds and shrimp have produced better results than pelleted feeds. Several authors have reported advantages using extruded feeds for production of L. vannamei; for example, some researchers have demonstrated that extruded feeds produced better growth than pelleted feeds (8.35 grams vs. 7.11 grams) in a controlled experimental system. Similar results have been reported for other cultured crustaceans; for example, postlarvae of giant river prawn (Macrobranchium rosembergii) fed an extruded feed had better specific growth rate and protein efficiency rate compared to a pelleted diet, and nutrient loss and feed conversion were lower with the extruded feed treatment.

Field performance

We assessed the effect of extruded feed on shrimp growth, survival, feed conversion, cost of production and economic performance, by evaluating data from 271 production cycles between January and October 2019 in shrimp farms located in the Gulf of Guayaquil.

For this analysis, we selected shrimp ponds that had received nutritionally complete, 35 percent protein feeds and were fed manually, and these ponds were grouped based on whether they had received extruded or pelletized feeds during the production cycles. Initial shrimp weights in these ponds were 0.4 to 0.6 grams, and stocking densities were 13 to 15 postlarvae per square meter. Production cycles lasted for 104 to 119 days depending on the harvest weight targeted.

Results of our data analyses show that manual feeding reduced feed conversion by 17 percent in ponds receiving extruded when compared to ponds receiving pelleted feeds (Fig. 1).

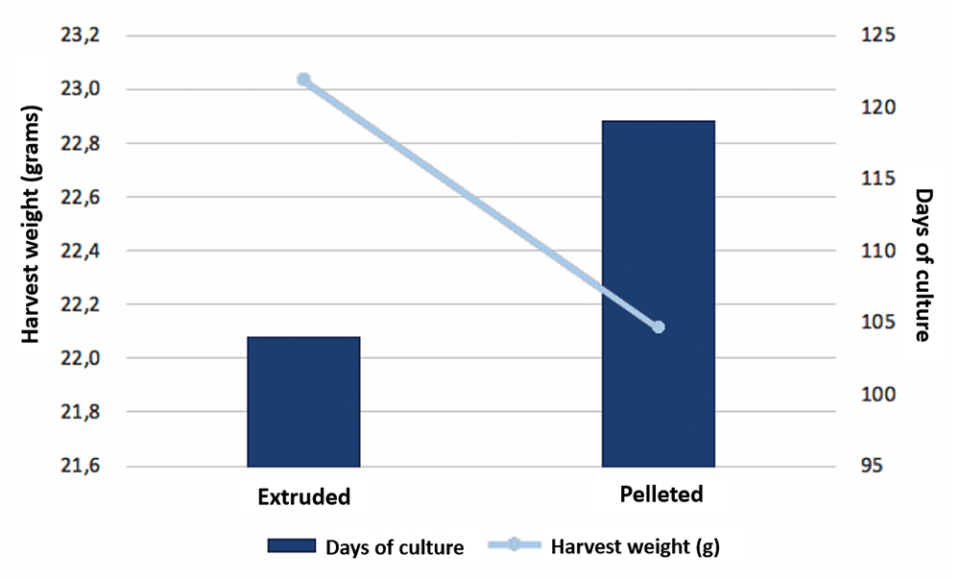

The weekly increase in weight was 11 percent higher in ponds receiving extruded feeds, and this was reflected in larger harvest weights produced in a significantly fewer time – around 15 days (Fig. 2).

The survival rate was 7 percent higher in ponds receiving extruded feeds compared to ponds fed pelleted feeds (Fig. 3). It is likely that shortening the production cycle had an effect on this parameter, as the former had less exposure time to environmental changes and pathogens.

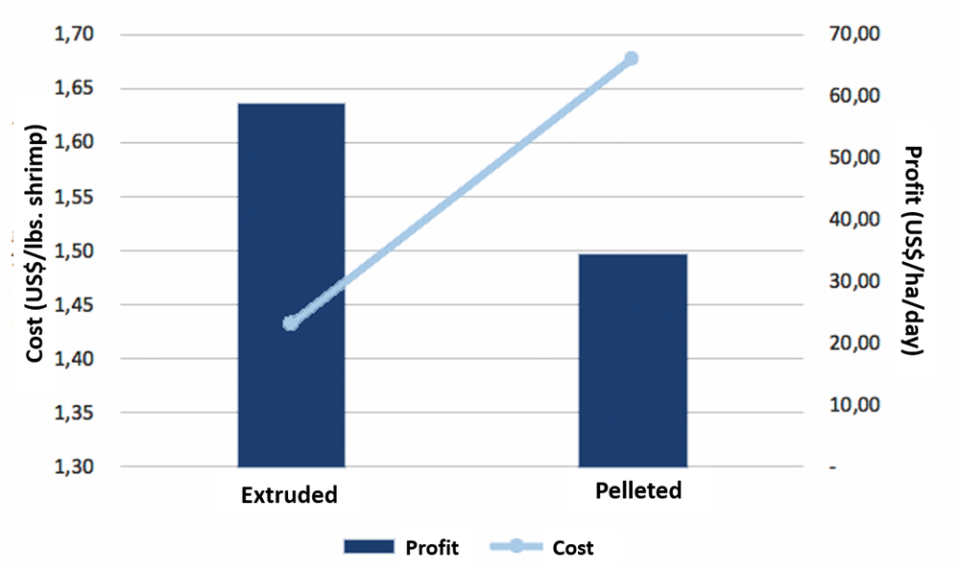

Regarding economic performance – even feeding just once or twice per day –ponds receiving extruded feeds had a cost of production 90 percent lower per pound, and a 13 percent higher profitability than ponds fed with pelleted feeds (Fig. 4).

Conclusions

Our results demonstrate the beneficial effects on digestibility of proteins, amino acids and carbohydrates for shrimp feeds produced by extrusion compared to pelleted feeds. Increasing the bioavailability of these nutrients through extrusion manufacturing shows a positive effect in commercial ponds, with shorter crop cycles, a higher production yield using less feed per pound of shrimp produced, and a reduction in production costs.

References available in the original publication.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

César Molina, Ph.D.

Research & Development

Skretting Ecuador

Guayaquil, Ecuador

-

Manuel Espinoza, M.Sc.

Research & Development

Skretting Ecuador

Guayaquil, Ecuador

Tagged With

Related Posts

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Aquafeeds

Fishmeal-free feeds for hybrid tilapia

A series of experiments showed that fishmeal is not an essential ingredient in hybrid tilapia feeds and that plant protein-based diets can yield results similar to those obtained with diets containing 10 percent fishmeal.

Health & Welfare

Feeds, feeding methods advance for largemouth bass

U.S. demand continues for largemouth bass in sport fish stocking and live markets, whereas Asian consumers prefer live largemouth over most freshwater fish.

Aquafeeds

A closer look at preconditioning: Mixing, residence time

During the aquafeed manufacturing process, preconditioning increases the moisture content and temperature of feed meal particles.