Digestible protein can be reduced without adversely affecting fish productivity indices

A biofloc technology (BFT) production system is used to intensify aquaculture production because it maintains water quality conditions conducive to rapid growth in densely stocked and intensively fed culture species.

In the outdoor BFT system used here, algal uptake mainly controls excreted feed nitrogen (total ammonia-nitrogen, TAN) for the first several weeks and then nitrification predominantly controls TAN for the remainder of the culture cycle.

Tilapia can consume this microbial biomass, which can substitute for protein in the formulated ration, thereby increasing overall efficiency of protein utilization. Much subsequent published research on the tilapia BFT production system focuses on the efficacy of various types of organic matter and/or the optimal carbon-nitrogen (C:N) ratio.

Surprisingly, only two published studies were found that evaluated formulated diet protein levels for growing fingerling- or juvenile/stocker-size tilapia in the BFT production system. In both studies, exogenous organic carbon was added daily or periodically. No published reports were found that evaluated protein content of formulated diets for BFT production of market-size tilapia.

Ideal protein (IP) theory has been used to formulate diets for production of fingerling or juvenile tilapia in aquaria, recirculating aquaculture system (RAS) tanks, or net pens, but not for fast-growing tilapia to market size in a BFT production system. An alternative approach for reducing intact protein in the diet is to use a balanced amino acid ratio while reducing DP versus supplementing the limiting AA to target an absolute quantity of AA based on an estimated protein requirement.

Therefore, one can increase the number of supplemental limiting amino acids included in the formula targeting the IP concentrations for those amino acids at each level of reduced DP, rather than at the highest (or control) level of the series. Thus, both intact protein and the level of supplemental amino acids included in the diet are reduced, potentially decreasing diet cost and excess nutrient excretion.

This article – summarized from the original publication (https://doi.org/10.1016/j.aquaculture.2019.01.034) – reports on a study by the authors to test the hypothesis that significant reduction in protein could be achieved in hybrid tilapia (Oreochromis aureus×O. niloticus) reared to market size (454 grams per fish) in an outdoor, photoautotrophic/chemoautotrophic BFT production system without constant organic carbon additions by supplementing the first four limiting amino acids (Lys, Met, Thr, Ile) and formulating to the IP profile (muscle) at each level of tested DP.

We thank David Brock and Rangen, Inc., for their collaboration in extruding the diets, and Evonik Industries, Essen, Germany, for providing the amino acids. We also thank several USDA-ARS personnel for their support. This study was funded by USDA-ARS under project 6028-31630- 008-00D.

Study setup

The feeding trial was conducted at the Harry K. Dupree Stuttgart National Aquaculture Research Center (Agricultural Research Service, ARS, United States Department of Agriculture) in Stuttgart, Ark., USA. Nine outdoor wood-framed rectangular BFT production tanks (18.6 square meters, 16.6 cubic meters) with a slightly sloped bottom and lined with high-density polyethylene. The experimental system was aerated with regenerative blowers that supplied air continuously to two diffuser grids on the bottom of each tank. Two conical-bottom settling chambers (each 130 liters, 117-liter operating volume) connected in series were installed at each tank.

All-male hybrid tilapia fry were sourced from a commercial supplier (Aquasafra, Inc., Bradenton, Fla., USA) and reared indoors until stock out. Initial stocking weight into the experimental outdoor system was 32.2 ± 10.1 grams per fish (mean ± SD) and initial biomass was 0.9 ± 0.01 kg per cubic meter.

Using a completely randomized design in triplicate outdoor tanks, hybrid tilapia were fed three practical test diets for five months. Diets were to contain one of three digestible protein (DP) levels (22.5 percent, 27.7 percent and 32.3 percent). Diets were supplemented on an IP basis with the first four limiting amino acids (Lys, Met, Thr, Ile) according to the tilapia muscle amino acid profile at each of the targeted diet DP levels. Fish were fed their randomly assigned test diet by hand to apparent satiation twice daily during the week and once daily on weekends for 122 days.

For additional information and details on experimental design and diet; tank management, fish, and feeding; fish and tissue sampling; diet and tissue chemical analyses; 2-methylisoborneol (MIB) and geosmin analyses; and statistical analyses, please consult the original publication.

Results and discussion

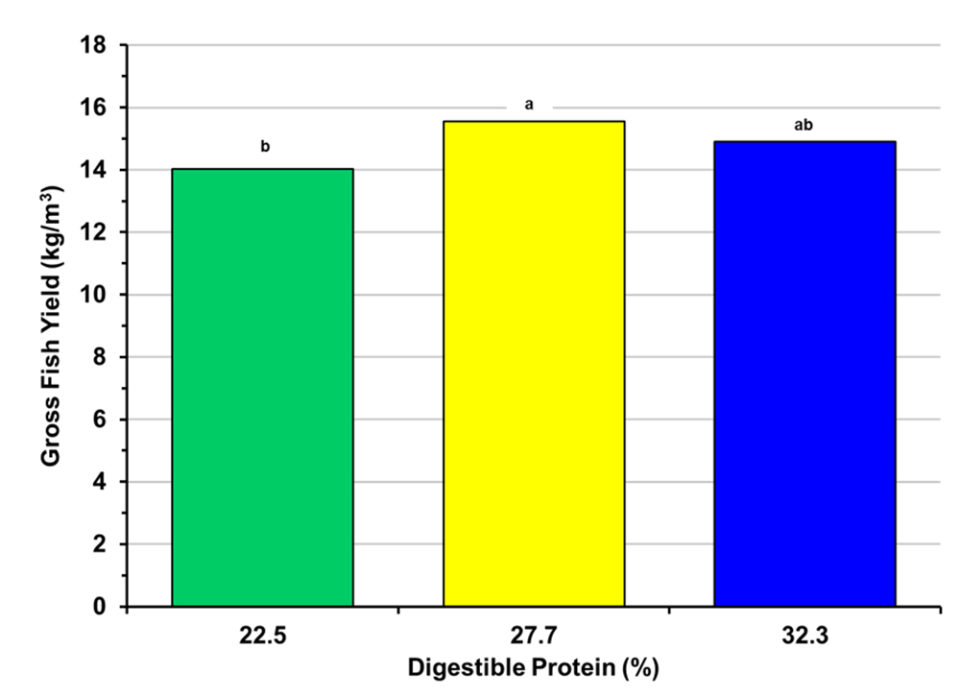

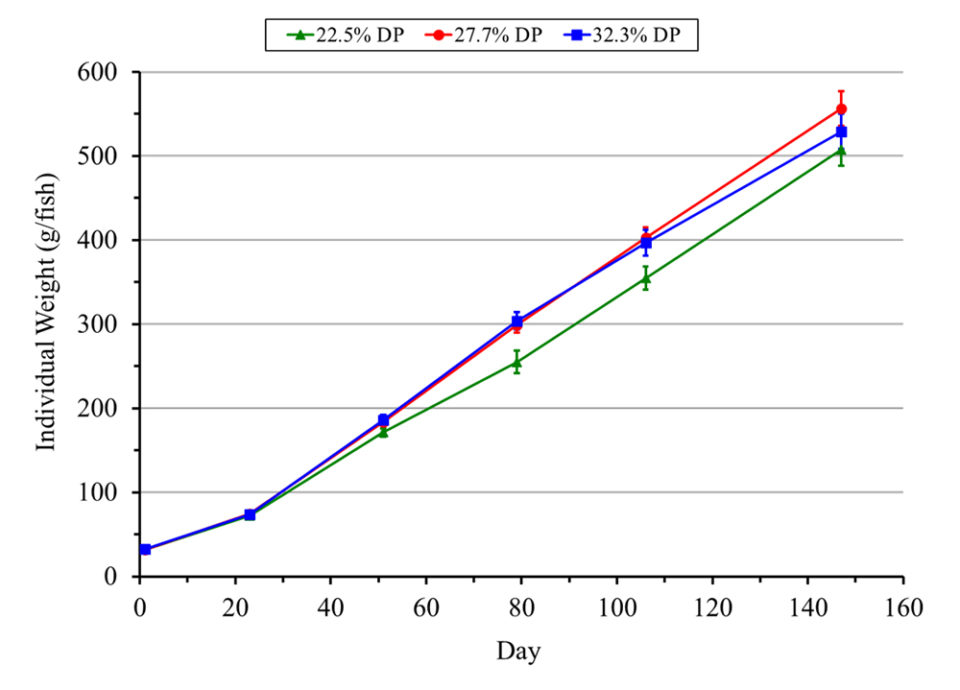

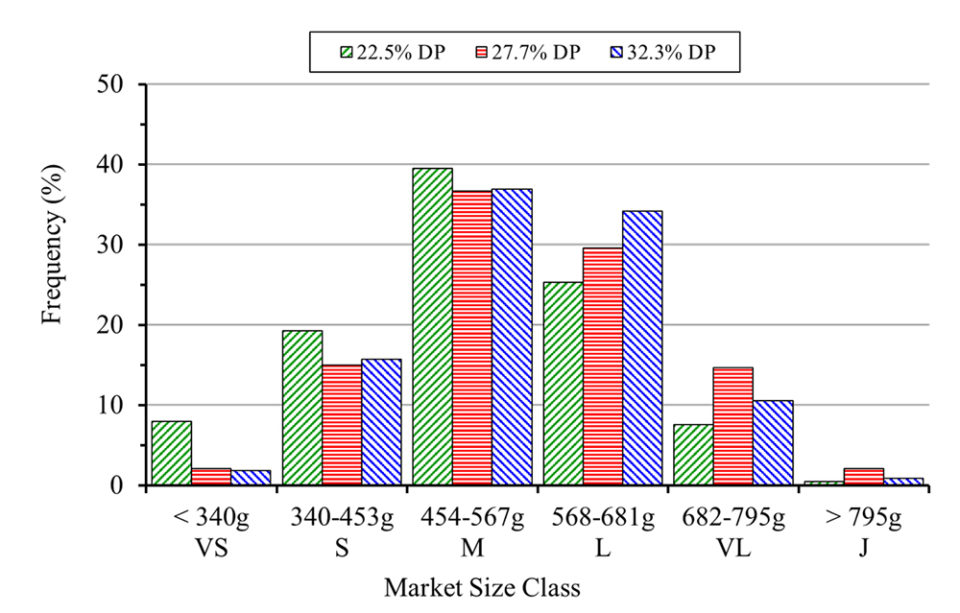

The results for gross fish yield (Fig. 2) net fish yield, weight gain and the percent of fish larger than 454 grams were significantly greater in the 27.7 percent DP treatment than in the 22.5 percent DP treatment, while the 32.3 percent DP treatment was intermediate. Once feeding of test diets began, the growth curve slope for fish fed the 27.7 percent DP diet was significantly greater than that for fish fed the 22.5 percent DP diet (3.56), while the 32.3 percent DP diet growth curve slope was intermediate (Fig. 3). Average final weight was significantly smaller and FCR was significantly greater in the 22.5 percent DP treatment than in the other two treatments, which did not differ.

Total feed nitrogen and phosphorus, liver size (HSI), and muscle ratio in the 27.7 percent DP treatment were intermediate to the other two treatments, which differed significantly. Daily feed ration did not differ significantly among diets and averaged 158 grams per cubic meter, 162 grams per cubic meter, and 154 grams per cubic meter for the 22.5 percent, 27.7 percent and 32.3 percent DP treatments, respectively. All remaining response variables were independent of dietary digestible protein.

This is the first report that evaluates the effect of dietary protein content on hybrid tilapia productivity in a photoautotrophic-chemoautotrophic BFT system and results indicated that dietary digestible protein could be reduced from 32.3 percent to 27.7 percent with no adverse effect on tilapia production, but a reduction from 27.7 percent to 22.5 percent DP caused a significant decrease in tilapia growth and yield. Thus, only as digestible protein decreased from 32.3 percent to 27.7 percent did grazing on the biofloc by tilapia appear to substitute for dietary protein.

The absence of significant treatment differences in mean chlorophyll a and TSS concentrations suggests that biofloc quality and quantity was similar among treatments, which when considered along with the similar quantities of feed fed among treatments suggests that available nutrition in the 22.5 percent DP treatment may be insufficient to sustain fast growth.

Biofloc derived from heterotrophic bacteria contains on a dry matter basis 25 percent protein and 7.2 percent lipid, and while its essential amino acid profile indicates it is a useful protein source for tilapia, Met, Arg, and Lys are relatively deficient. However, biofloc management protocols, i.e., exogenous organic carbon source and target C:N ratio, affect biofloc protein content as indicated by reported crude protein (dry matter basis) values that range from 14.2 percent to 41.2 percent. Tilapia consume biofloc readily and retain 24 to 32 percent of biofloc nitrogen, suggesting that biofloc can substitute for a portion of the daily ration of formulated feed.

However, the degree to which biofloc can substitute for formulated feed protein appears to vary with life stage. Our results showed that formulated feed digestible protein could be reduced 32.3 percent to 27.7 percent when growing tilapia to market size.

FCR values became slightly poorer (increased) at the lowest DP in market size tilapia. Hepatosomatic index (HSI), typically a sensitive indicator of diet nutrient balance, increased slightly with decreasing DP in the current study, whereas body fat (IPF) was unaffected by the three levels of DP tested.

Retention efficiencies of protein and amino acids in tilapia tend to increase, while tissue levels of protein and hence amino acids tend to decrease in fish with decreasing DP in the diet, as seen in our results. Differences in amino acids composition of muscle and whole-body were seen primarily in decreased concentration at the lowest of the three tested DP levels, albeit the magnitude of the changes was small (< 0.25 percent) but statistically significant. This response in combination with the lack of significant differences in muscle and whole-body proximate composition suggest all three test diets were balanced sufficiently to meet basic metabolic needs but insufficient to meet maximum performance potential at the lowest tested DP.

Interestingly, among the four supplemented amino acids, Lys retention (≈ 30 percent) and Lys muscle concentrations (≈ 1.6 percent) were completely unaltered by diet DP level. This suggests that diet levels of Lys may have been first limiting. The drop in whole-body Lys at the lowest DP level (from 1.19 percent to 1.17 percent to 1.09 percent) as well as similar drops seen in whole body levels of several essential amino acids at the lowest diet DP substantiates the inadequacy of the 22.5 percent DP diet for maximum performance of Nile tilapia in BFT. All relevant studies conducted in tilapia thus far have found that 22.5 percent DP is too low for optimum production, whereas about 25 to 27 percent DP appears appropriate for fast growing tilapia to market size if careful attention is paid to diet formulation and feeding.

The question remains as to whether further reduction in protein, between 27.7 percent and 22.5 percent DP, is possible for production of market-size tilapia in the current or similarly managed BFT systems. For the matrix of ingredients used in our study, we found Ile fourth-limiting as opposed to Arg. Moreover, Arg concentrations in whole body and muscle did not vary markedly (≤ 0.04 percent) in response to the dietary treatments of our study. Secondly, we targeted the ideal protein concentrations for limiting amino acids at each level of reduced DP, rather than a higher level of DP as in other studies.

Tilapia tainted by MIB and geosmin have been reported for fish produced in pond culture and in RAS, but no previous reports were found for tilapia produced in the biofloc system. Tank aqueous MIB and geosmin dynamics in the present study were similar to those observed in earlier studies on channel catfish in our biofloc production system. The highest mean concentration of MIB (47.3 ng/L) and geosmin (211.1 ng/L), observed in the 27.7 percent DP treatment on day 141, was lower than >700 ng/L MIB and >2,000 ng/L geosmin that can occur in earthen catfish pond water in the southern USA.

Despite the nutrient transformations that occurred in the settling chamber, nitrogen and phosphorus concentrations in the BFT system remained high because of nutrient cycling. More research is needed to optimize nitrogen (denitrification) and phosphorus (biological) removal to minimize environmental impact of discharge from the system. Refinements in diet formulation using ideal protein theory and incorporation of enzymes that improve nutrient retention also are needed.

Perspectives

The apparent grazing of biofloc by hybrid tilapia appeared to allow diet digestible protein to be reduced to 27.7 percent from 32.3 percent with no adverse effects on fish production. However, grazing the biofloc did not compensate for further reducing diet DP to 22.5 percent, which decreased tilapia production significantly and shifted fish to smaller size classes (Fig. 4). Fish fed the 22.5 percent DP diet converted feed less efficiently but retained protein as efficiently as those fed the 27.7 percent DP diet, whereas the lower PRE for fish fed the 32.2 percent DP diet suggests excessive dietary protein content.

Tilapia grazed on the water line biofilm/crust, which contained high concentrations of MIB and geosmin, and was the suspected main source of these off-flavor compounds in the fish flesh. Effective measures are needed to control sources of MIB and geosmin for viable tilapia production in the BFT system. Accumulation of nitrogen and phosphorus in tank water was related to feed protein and phosphorus content and high feeding rate.

Stable concentrations of solids and phytoplankton were maintained using side-stream settling chambers. Nitrate transformation in settling chambers was by denitrification, which appeared to account for 25 to 30 percent of total feed nitrogen, and by DNRA. However, nutrient cycling between the culture tank and settling chambers resulted in sustained high nitrogen and phosphorus concentrations. Further refinements are needed to improve retention of dietary nutrients and to optimize processes for nitrogen and phosphorus removal from the BFT production system.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Bartholomew W. Green, Ph.D.

United States Department of Agriculture

Agricultural Research Service

Harry K. Dupree Stuttgart National Aquaculture Research Center

P.O. Box 1050

Stuttgart, AR 72160-1050 USA -

Steven D. Rawles, Ph.D.

United States Department of Agriculture

Agricultural Research Service

Harry K. Dupree Stuttgart National Aquaculture Research Center

P.O. Box 1050

Stuttgart, AR 72160-1050 USA -

Kevin K. Schrader, Ph.D.

United States Department of Agriculture

Agricultural Research Service

Natural Products Utilization Research Unit

National Center for Natural Products Research

P.O. Box 1848

University, MS 38677-8048 USA -

T. Gibson Gaylord, Ph.D.

U.S. Department of the Interior

Fish and Wildlife Service

Bozeman Fish Technology Center

4050 Bridger Canyon Road

Bozeman, MT 59715 USA -

Matthew E. McEntire

United States Department of Agriculture

Agricultural Research Service

Harry K. Dupree Stuttgart National Aquaculture Research Center

P.O. Box 1050

Stuttgart, AR 72160-1050 USA

Tagged With

Related Posts

Health & Welfare

Barcoding, nucleic acid sequencing are powerful resources for aquaculture

DNA barcoding and nucleic acid sequencing technologies are important tools to build and maintain an identification library of aquacultured and other aquatic species that is accessible online for the scientific, commercial and regulatory communities.

Intelligence

Adding flavor complexity to farmed barramundi

Organoleptic attributes such as flavor and aroma are among the most important factors that influence consumer acceptability and demand for fish products. Consumers have identified farmed fish as less complex and lacking “sealike” or “sea-fresh” flavors and aromas.

Intelligence

Off-flavors in aquaculture products, part 1

Off-flavors in pond and recirculating aquaculture systems have occurred through the biological production of geosmin and 2-methylisoborneol. The compounds are rapidly absorbed through the gills of fish, but depuration can require days or weeks.

Intelligence

Moisture-retention treatments connected to odors in tilapia fillets

An investigation into ammonia-like odors in tilapia fillets that could result in product rejection traced the source to moisture-retention chemicals.