Removal of ammonia and nitrite improves water recirculation, lowers waste discharges

Nitrogen removal is the most important process for the efficient use and reuse of water in aquaculture. In recirculating aquaculture facilities, fish may be grown at 100 times the density found in aerated ponds, but these high densities cannot be sustained without artificial intervention and water purification that lessens the toxic effect of nitrogenous compounds on the cultured animals. The design and operation of biofilters is multidisciplinary, involving mechanical engineering, microbial ecology, and aquaculture husbandry. Much effort has been devoted to improving biofilters for aquaculture use.

However, the research on the microbiology of nitrifying biofilters has lagged behind. As a result, many aquaculture biofilters do not perform up to their potential, because the biological problems in biofilter performance (which are caused primarily by microbial competition and interference) have largely not been addressed.

Biofilters in aquaculture

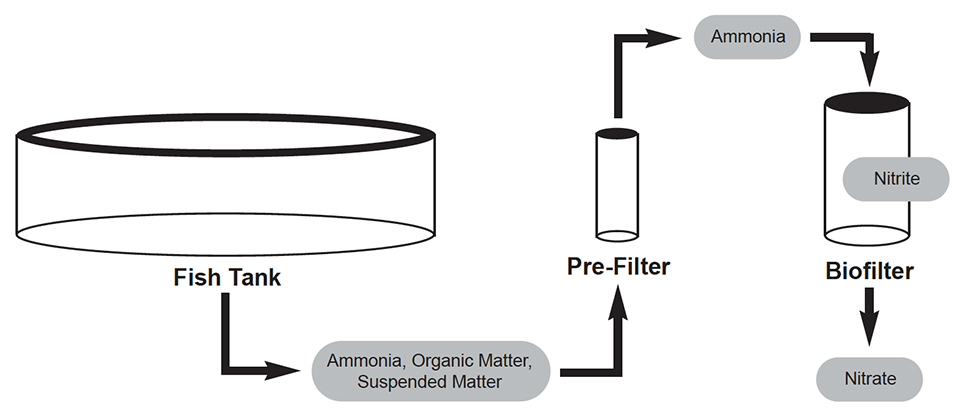

Various types of nitrifying biofilters are in use in intensive recirculating aquaculture systems, including rotating biological contactors (RBC), trickling filters, and fluidized bed filters that operate with either sand or plastic beads. Each of these biofilters contains a solid support medium on which microorganisms settle over time. Thus, a nitrifying biofilter consists of both mechanical and microbiological components. There is a high level of suspended matter in many aquaculture facilities, so a suspended matter removal device should be placed in front of the biofilter to prevent rapid fouling of the biofilter.

Improving and managing the nitrification process

Nitrification rates in biofilters can be increased with improvements in the activity and stability of the nitrifying bacteria. In order to have an efficient nitrifying biofilter in a recirculating aquaculture system one should:

- Use a biofilter support medium that is not toxic and has a high surface area available for bacterial adhesion.

- Pre-coat the biofilter support medium with a stable, long-lasting biofilm of nitrifying bacteria that have been selected for improved nitrification activity, strong adhesion to the biofilter surface, and resistance to inhibitors in the aquaculture environment.

- Clean the support medium to conserve the original pre-coated nitrifying biofilm layer and prevent smothering of the nitrifiers by an overgrowth of heterotrophic biofilm.

Surface area available for bacterial attachment in biofilters

The level of ammonia and nitrite oxidation by microorganisms in a biofilter depends on two factors: the nitrification activity of individual bacteria, and the number of nitrifying bacteria present in the biofilter. The latter depends on the surface area available for their adhesion. Increasing the surface area of a biofilter that contains solid support particles can be achieved by increasing the volume of the biofilter, decreasing the size of the particles, or using particles that have additional internal surface area. Each approach has its limitations. Increasing the size of the biofilter makes it more expensive to build and operate. Using smaller floating solid support particles in a biofilter requires the use of screens with a smaller hole size to contain these particles, which makes the screens more susceptible to biofouling. In fluidized sand filters, where the particles are heavier than water, special attention has to be given to the amount of energy that is used for fluidizing the sand to avoid loss of sand from the biofilter. Lastly, under most aquaculture conditions, increasing surface area by adding internal pores to the solid support particles results in blocking access to these internal surfaces due to biofouling.

Potential toxicity of biofilter material

It is important to make sure that the synthetic polymeric materials used in the biofilter, especially those that serve as the solid support for microbial attachment, are non-toxic to the nitrifying bacteria. Several synthetic polymers contain small molecules that can leach out of the polymer and inhibit nitrification. In some cases, prewashing or pre-treatment of the plastic material can remove the toxicity.

Methods to improve performance of nitrifying bacteria

The performance of nitrifying bacteria can be improved by microbial manipulations, which entail passing populations of bacteria, isolated from natural and aquaculture environments, through cycles of enrichment and selection under desired conditions. For example, the water in recirculating aquaculture systems may contain chemical and biological factors that hinder microbial nitrification.

Using microbiological manipulations, one can overcome the various nitrification inhibitors. The resulting ammonia- and nitrite-oxidizing bacterial populations should be able to resist the nitrification inhibitory factors in the aquaculture facility, which would lead to improved biofilter performance. Similarly, nitrifying bacteria can be manipulated to obtain microorganisms with higher affinity to the biofilter solid support media, which results in improved attachment and stability. In addition, one can select for bacteria with higher nitrification rates, and overall better nitrification efficiency. Remember that the nitrifying microorganisms that function in freshwater environments are, in most cases, different from those of marine environments, even though their biochemical activity in nitrification is the same.

Pre-inoculation of biofilter material with nitrifying bacteria improves nitrification stability. The success of the microbial pre-coating method in both fresh and marine water is due to the nitrifying bacteria occupying the innermost layer of the biofilm in large numbers, thus being more resistant to toxic effects and shifts in microbial population.

Cleaning the support media to conserve the nitrifying biofilm layer

Cleaning the biofilter’s solid support media is crucial in order to conserve the original pre-coated nitrifying biofilm layer, and prevent smothering of the nitrifiers by an overgrowth of a heterotrophic biofilm. Gentle cleaning of the biofilter has a rejuvenating and cleansing effect on the nitrifying bacteria. However, if the cleaning is too vigorous or too frequent, it may negatively affect nitrification.

Start-up time in biofilters

The common start-up time for new nitrifying biofilters by natural microbial settlement is several weeks, and the outcome is not predictable. The buildup of microbial populations under such conditions is largely left to chance, allowing the heterotrophic microorganisms a free hand at the expense of the more sensitive nitrifying autotrophs. Pre-coating the biofilter with selected nitrifying bacteria eliminates this transition period and the uncertainty associated with it.

Biofilters and pathogens

The same solid support media that allow nitrification to occur may also harbor pathogens. Therefore, nitrifying biofilters, if not treated correctly, may result in a negative outcome. It is wise to clean the biofilters between crops. Pathogens that settle on the biofilter are removed during the cleaning phase, thus reducing the pressure of disease on the culture animals. In aquaculture facilities that experience disease outbreaks, periodic sterilization of the biofilter may be required. In small-volume aquaculture systems such as hatcheries, it is advantageous to have a second biofiltration system, in order to alternate between cleaning the biofilter and using the biofilter for nitrification. If used properly, a dual biofiltration system will aid in reducing the number of pathogens in the water.

Biofiltration and the environment

The development of wasteful forms of aquaculture, which use high amounts of water exchange and take a heavy toll on the environment, is limited due to regulatory restrictions, competition with other industries such as tourism, and lack of resources. Thus, future development of aquaculture will have to concentrate on systems that function with low amounts of water, produce less waste, and are located in areas where the demand for land is lower and which are less environmentally sensitive.

It is possible to construct and operate such systems with the aid of biofiltration. Development of recirculating aquaculture will promote renewable and sustainable seafood supply, a decreased environmental impact and use of natural resources, a reduction in waste and the energy associated with its treatment and disposal, and an increase in economic viability of recirculating aquaculture that can be located in arid areas and in areas distant from the sea.

Conclusions

Improved removal of ammonia and nitrite from the water surrounding the cultured animals will make it possible to increase water recirculation and to lower waste released by aquaculture farms. More efficient recirculating systems will promote development of recirculating aquaculture, and will aquaculture facilities to locate away from water sources and closer to the marketplace. In order to achieve and maintain optimal, efficient and stable nitrification activity in biofilters of recirculating aquaculture systems, one needs to follow the following recommendations:

- Use nitrifying bacterial cultures that resist adverse conditions in aquaculture.

- Pre-coat the biofilter solid support media with nitrifying bacterial cultures of high nitrification rates.

- Remove organic matter prior to nitrification.

- Have a good biofilter design that includes gentle periodic cleaning.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Dr. Ami Horowitz

UPAH Tech, Inc., Aquaculture

and Environmental Microbiology

Shaker Heights, Ohio 44122 USA

-

Dr. Sarah Horowitz

UPAH Tech, Inc., Aquaculture

and Environmental Microbiology

Shaker Heights, Ohio 44122 USA

Related Posts

Intelligence

Bead filter enhances RAS for tilapia production

The performance of a bubble-washed bead filter with partial solids removal was evaluated at the University of Arkansas in Pine Bluff.

Intelligence

Biofilters: Choosing your substrate

Heterotrophic and autotrophic bacterial communities supported within a biofilter naturally process organic wastes and provide biologically stable water.

Innovation & Investment

Getting proficient in RAS fundamentals

A number of large salmon farming companies are now investing significantly to increase land-based, water recirculating aquaculture systems (RAS) in northern Europe and North America, and there is likely a need for more trained farm personnel to run and manage these and other close-containment aquaculture facilities.

Responsibility

Aquaculture and the microbial world

Microorganisms reside in the sediment and other substrates, and in the water of aquaculture facilities, as well as in and on the cultured animals.