Australian Redclaw Crayfish Hatchery and Aquaculture Supplements hope the Fish 2.0 springboard leads to new opportunities

Upside down maps are reportedly popular in Australia. Maybe that’s simply because they put the land Down Under on top.

Getting to the top is what Australia’s aquaculture industry is pursuing. An indication of this effort is the strong showing of Australian entries at the 2019 Fish 2.0 Global Innovators Forum in November.

“We are seeing many top-notch innovations emerging from strong scientific programs led by universities and governments, and now being commercialized by expert teams,” observed Monica Jain, Fish 2.0 founder and director. “Australia has the potential to become a leader in aquaculture for several niche species as well as for technologies around genetics, disease control and farm management.”

Redclaw crayfish certainly qualifies as niche. The winner of the Australian Fish 2.0 category, the Australian Redclaw Crayfish Hatchery, produces this native species in Townsville, Queensland, Australia. Redclaw crayfish grow quickly and have a simple life cycle, making them relatively economical to produce, according to the company.

The hatchery supplies craylings to farms that grow these juvenile crayfish into product for sale. The company claims that its craylings are healthy, disease-free, antibiotic-free and generally more pathogen-resilient than craylings from other sources.

Among other innovations, the company invented its own proprietary feed and feeding method, said CEO Lisa Elliott.

“Not only did we develop a proprietary feed, we also improve – quite dramatically – the way the nascent craylings are being fed,” she said. “This involved studying closely animal behavior, which led to an out-of-the-box innovative solution, resulting in measurable outcomes.”

She added that the feeding method can be likened to the design of a baby bottle, which is equipped with a device that mimics a mother’s nipple. The company’s solution, the details of which are confidential, is similarly based on how the young of a species, in this case craylings, feed naturally.

The feed is derived from the mealworm beetle, which is processed into something suitable for craylings using what Elliott described as a unique approach. The combination of feed and feeding method have resulted in more resilient, energetic and healthy craylings, Elliott said.

An innovation that is will be deployed this spring involves a custom designed vertical breeding facility, with tanks stacked atop one another so that they are readily accessible like drawers in a cabinet. This arrangement, the company states, is the first of its kind in the world dedicated to the Australian redclaw crayfish. The intent of this approach is to reduce labor and guess work in egg production from top-quality females. This will lead to steady supply of quality crawfish eggs with superior genetics, Elliott predicted, thereby addressing a pressing need for growers in the region.

Traditional aquaculture methods, which are horizontal, result in high mortality of eggs and poor crayling survival, she added. Going vertical means that systems can be housed in a climate-controlled environment, with recirculation minimizing water usage and waste. What’s more, the systems – and the broodstock within them – will be protected against pathogens, with monitoring to ensure healthy conditions. Finally, the systems will be independent of each other, protecting against possible cross contamination.

Bottom line, Elliott said, going vertical helps “achieve significant efficiencies throughout, guaranteeing the success of the broodstock and breeding program.”

Solutions in small packages

A second example of ingenuity from Down Under comes from Brisbane, Queensland, Australia-based Aquaculture Supplements. The newly formed company is commercializing an innovation for parasite treatment of farmed fish – its presentation at Fish 2.0 detailed how this technology can be applied to salmon.

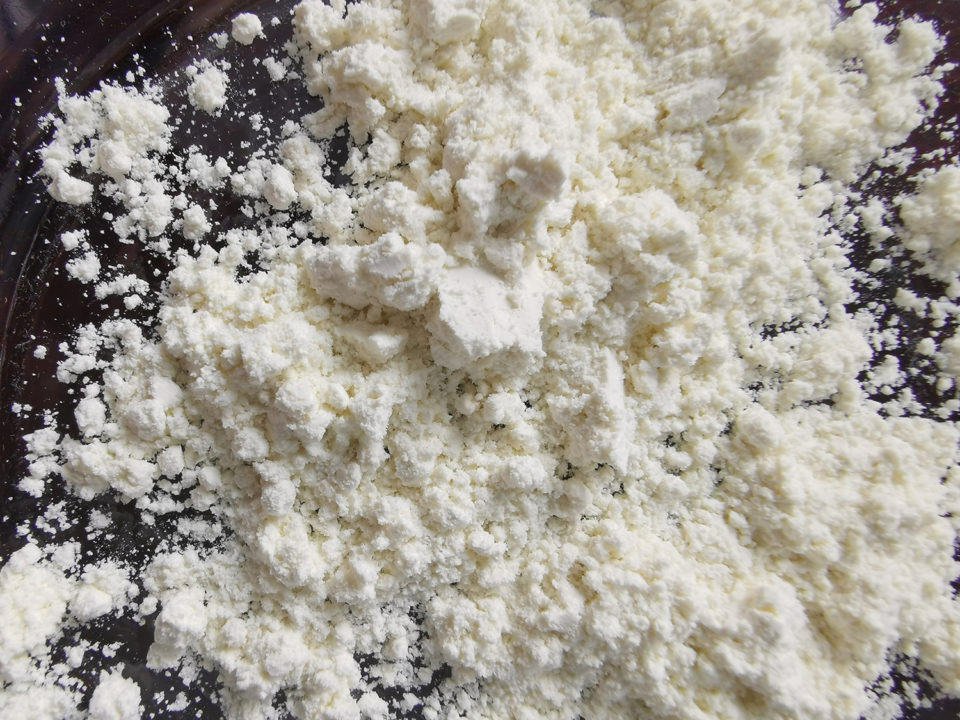

Developed by a team of Australian and Canadian scientists, the product is a bioactive, microfine encapsulated powder. As is the case with other parasite treatment technology, the Aquaculture Supplement product had to satisfy several conditions.

“You need something that is effective in the therapeutic goal you’re seeking. It has to be completely nontoxic to the species you’re treating,” said Suzanne Catty, the company’s Toronto-based director of business development. “It should also be nontoxic to the environment in which that species lives. And it needs to be a form that is also economically sustainable.”

Microencapsulation, which surrounds the treatment agent with a miniature protective shell, solved two problems, she added. The first was palatability and coating the product made fish more willing to consume the supplement.

The second problem dealt with by microencapsulation is that any supplement must be soluble in water and therefore have a high bioavailability to the fish being treated. Coating the plant derived parasite suppressor helps achieve that goal, meaning that less product is needed to achieve the same result, Catty noted.

According to Catty, the genesis for the first Aquaculture Supplements product was a request to develop a treatment for sea lice in salmon. Tests have shown that the supplement does treat the parasite, with the now healthier fish gaining more weight for the same amount of feed, Catty reported.

The company is doing research into and development of supplements targeting health problems in other species, she said. Some of the possible candidates are tilapia, barramundi and shrimp.

Aquaculture Supplements’ first product will be certified organic. That is also likely to be the case for follow-on products, given the company’s emphasis on sustainability. Such a certification could distinguish the company’s products from other treatment approaches, such as the use of antibiotics. That may help address regulatory concerns and may aid in marketing the treated fish.

The Aquaculture Supplements business model is to license the technology. Part of the reason for this approach, according to Catty, is that establishing large-scale production would be expensive.

Surveying the state of Australian aquaculture innovation, Catty noted some interesting developments on the way, such as new nets, new approaches to density of fish, and new ways to deal with deep water situations. These and other improvements could benefit the industry and help move it up in the world – without having to flip the map.

Follow the Advocate on Twitter @GAA_Advocate

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Hank Hogan

Hank Hogan is a freelance writer based in Reno, Nevada, who covers science and technology. His work has appeared in publications ranging from Boy’s Life to New Scientist.

[109,111,99,46,110,97,103,111,104,107,110,97,104,64,107,110,97,104]

Tagged With

Related Posts

Aquafeeds

Aquaculture Exchange: Giovanni Turchini, Deakin University, part 1

One of the world’s leading fish nutrition experts talks about how aquaculture can learn to survive, and even thrive without depending on fishmeal and fish oil. It’ll take a lot of innovation, but Giovanni Turchini is confident that the industry is on the right path.

Innovation & Investment

Australia incentivizing innovation in aquaculture

A government-funded $3 million (AUS) project by innovationXchange, WWF and others seeks transformative solutions from entrepreneurs for small-scale producers in the Indo-Pacific region. The competition’s three challenges include fresh thinking on feed, “new ocean products” and sustainable design.

Innovation & Investment

Global Aquaculture Innovation Award 2019 finalist: Pegasus Science

Global Aquaculture Innovation Award finalist Pegasus Science aims to simplify mycotoxin measuring in aquafeeds with near infrared (NIR) spectroscopy.

Innovation & Investment

Bringing Australian aquaculture into view

Australian aquaculture gets some needed attention later this month when Fish 2.0 holds a regional workshop focused on innovation and investment in Melbourne.