Results show technology’s major potential

This article presents results from an in-pond raceway system (IPRS) pilot project culturing red tilapia on a commercial farm in Honduras. Adoption of this technologyhas been supported by the U.S. Soybean Export Council (USSEC) as a strategy to increase fish production, reduce environmental impact by improving feed management, and managing the waste load from high level production.

Although this approach has been adopted and implemented by aquaculture producers in China, Southeast Asia, India and Egypt, it has been recently tested in Latin America, specifically in Mexico, and now Honduras.

Honduras produces both standard Nile tilapia and red tilapia (Oreochromis sp.) in freshwater ponds, raceways and cages placed in reservoirs and natural lakes, using a variety of production systems. Most of the small and medium volume producers grow red tilapia, because there is a high demand and better prices in restaurants and supermarkets due to its attractive look compared to standard Nile tilapia.

One of these medium-sized producers – the farm “Tilapia Blukalsa”– is located in Las Marias, a small town located in Cortes Province, Honduras. The farm was established in 2015 and quickly experienced problems with its production model, primarily due to the farm being located at the lower end of a watershed and using sheet flow (runoff) water from within the watershed, which contains runoff from farms located at higher elevation.

Despite using water containing organic loading from these farms, no nitrite or ammonia were detected. However, total alkalinity of the water was measured at 22.0 mg/L, and it was amended to 60.0 mg/L using applications of agricultural (dolomitic) limestone. Water temperature in the farm ponds ranged from a minimum of 28 degrees-C to a maximum of 30 degrees-C. Issues with reduced dissolved oxygen (DO) measured in the ponds and due to high stocking densities have been resolved by implementing mechanical aeration in all the farm ponds, but the owner reasoned that more could be done to optimize pond production, and decided to explore the IPRS technology to increase their productivity and profitability.

Demonstration project

In April 2018, construction of a single concrete IPRS was initiated in a 0.36-hectare (ha) traditional earthen pond with an average depth of 1.4 meters. The raceway (5 meters x 25 meters x 1.40 meters; 175-cubic-meter raceway volume and a freeboard of 0.30 meters) was built as a fixed-floor project, with poured concrete walls.

The total culture area of the raceway for holding and growing fish is 125 square meters, which represents 3.5 percent of the total surface area of the production pond but very importantly, only 1.1 percent of its volume. The raceway is equipped with one regenerative blower providing 1.5 horsepower (60 Hz).

Additionally, the pond has Asian-style paddlewheels installed in the open water area, which helps mix and circulate water around the pond, to accelerate the assimilation of organic matter and nutrients produced by fish culture and feeding in the pond ecosystem. At the end of June 2018, the pond was filled and the IPRS was ready to stock. The investment installing a single raceway cell reached $10,259, including materials (50.7 percent), labor (25.3 percent), and equipment (24.0 percent) to be used in operating the raceway.

A total of 20,000 all-male graded red tilapia fingerlings with an average individual weight of 48 grams was stocked in the raceway. The initial stocking density of 114 fingerlings per cubic meter of raceway volume reached an initial biomass of 5.5 kg per cubic meter. The DO inside the culture was maintained at a minimum of 3.5 mg/L and while DO levels in the open pond exceeded saturation, the DO inside the raceway was maintained at saturation due to aeration. No nitrite was detected during growing cycle. Ammonia levels did not rise above 5 mg/L and pH was maintained between 7.5 to 8.0.

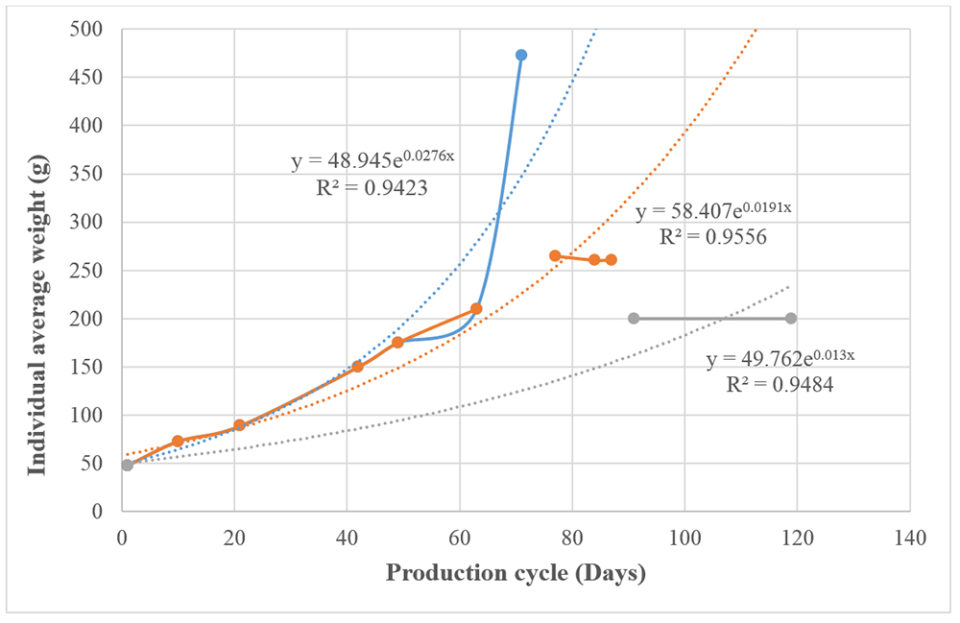

Daily feed applications in the raceway were made using a continuous satiation feeding protocol based on observed consumption. Fish were fed a commercial diet with 38 percent crude protein during the first 30 days (43 percent of total volume fed), followed by 35 percent crude protein (28.5 percent of total volume fed) and 32 percent crude protein (28.5 percent of total volume fed) over the course of the study. Two employees were responsible for feeding and cleaning the raceway screens to maintain the correct and continuous water flow in the raceway units. Fish sampling were performed at 10, 21, 42, 49, 63 and 77 days of culture. Four partial harvests were performed during the production cycle, at 71, 85, 91 and 119 days.

Results

This simple feeding demonstration was conceived as an illustrative pilot study to evaluate red tilapia performance in fixed concrete IPRS. Red tilapia fingerlings stocked at an individual average weight of 48 grams reached an average weight of 472.5 grams after 71 days of culture. A first partial harvest at 71 days removed 26.6 percent of the total number of individuals stocked, which eventually represented 51.3 percent of the total biomass (Table 1) at that time. Two weeks later, a second partial harvest was carried out which removed 30 percent of the population, but in this case, fish were only above half pound in size (260 grams). The remaining fish were fed for an additional month, and finally at 119 days of culture the fish were completely harvested.

Arana, IPRS, Table 1

| Variable | H-1 | H-2 | H-3 | H-4 | H-4 | Total |

|---|

Variable | H-1 | H-2 | H-3 | H-4 | H-4 | Total |

|---|---|---|---|---|---|---|

| Production cycle (days) | 71 | 85 | 91 | 119 | 119 | – |

| No. fish stocked | 20,000 | – | – | – | – | 20,000 |

| Fish harvested | 5,317 | 5,931 | 1,458 | 1,342 | 2,732 | 16,790 |

| Percentage of fish (%) | 26.6 | 29.7 | 7.3 | 6.7 | 13.7 | – |

| Survival rate (%) | – | – | – | - | – | 84.0 |

| Initial weight | 48 | – | – | – | – | – |

| Average weight(g) | 472.5 | 260.7 | 200 | 200 | 100 | – |

| Initial biomass (kg) | 960 | – | – | – | – | 960 |

| Partial harvest (kg) | 2,512.3 | 1,546 | 293.7 | 268.4 | 273.2 | 4,893.6 |

| Biomass (%) | 51.3 | 31.6 | 6.0 | 5.5 | 5.6 | 100.0 |

| Initial biomass (kg/m3) | 5.5 | – | – | – | – | – |

| Biomass harvested (kg/m3) | 14.4 | 8.8 | 1.7 | 1.5 | 1.6 | 28 |

| SGR (%/day) | 3.22 | 1.99 | 1.57 | 1.2 | 0.62 | – |

During these two partial harvests, at 91 days and 119 days, a total of 5,542 fish (27.7 percent of the population) were harvested, with half of them having an average weight of 200 grams, and the other half 100 grams, which represented 17.1 percent of the total biomass harvested. The final total yield reached for the IPRS in this trial was 4,893.6 kg (28.0 kg per cubic meter), with a survival rate of 84.0 percent. The estimated feed conversion ratio was 1.53. Considering the previous production parameters results, the potential red tilapia production for this unit could reach 40.8 tons/ha/year, assuming a production cycle of 120 days, which is 33.5 tons/ha/year higher than these ponds typically yield when traditionally managed without the IPRS.

The specific growth rate of the first group of fish harvested reached an SGR equivalent to 3.2 percent gain per day; but subsequent harvests did not show any improvement in growth. The SGR observed in the first group of harvested fish is slightly higher than the SGR obtained in a previous feeding demonstration with standard Nile tilapia in an IPRS system trial in Mexico.

Some researchers have pointed out that density may act as stress factor that affects growth and feed utilization due to stress caused by competition for space and feed. However, in this study, the density factor might have been alleviated with the removal of biomass in the first partial harvest. So, why the poor performance of the 73.4 percent of the red tilapia population, after the first partial harvest?

There is a strong indication that red tilapia is, in fact, more sensitive to manipulation and partial harvests may have prompted stress on the fish, possibly resulting in poor growth performance. Whether it is a biological factor associated with slower-growing individuals, fish handling, or poor feed management practices, requires further evaluation. For example, we know that in growth and performance trials on a commercial farm in Alabama, USA, channel catfish performed poorly when sampled frequently and/or partial harvests were used to meet market commitments. The catfish typically performs well in the raceway system environment but when managers sampled or harvested frequently, feeding response was poor.

Arana, IPRS, Table 2

| Variable | Cost (US$) | Proportion (%) |

|---|

Variable | Cost (US$) | Proportion (%) |

|---|---|---|

| Total fingerlings | 920.50 | 10.6 |

| Total feed | 5,147.50 | 59.30 |

| Total labor | 1,152.00 | 13.28 |

| Total electricity | 384.00 | 4.42 |

| Total office | 50.00 | 0.58 |

| Total variables | 7,654.00 | 88.18 |

| Annual depreciation | 1,026.00 | 11.82 |

| Total costs | 8,680 | 100.00 |

| Gross return from fish sales | 12,936.00 | – |

| Net income | 4,256.00 | – |

| Net profit (% total costs) | – | 49.03 |

| Net profit (% of sales) | – | 32.90 |

Perspectives

Although biological results may have been affected by excessive handling of the fish during the sampling and partial harvests, the financial results far exceeded traditional pond revenue returns. The sales of red tilapia at the conclusion of this trial returned 49.03 percent net profit as a percentage of total costs, or 32.90 percent net profit as a percentage of total sales and after only four months of production. This is a strong indicator of the efficiency and business potential of this IPRS technology from both the biological and economic points of view.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Esau Arana

Research Associate IV

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn, AL 36849 USA -

Jesse Chappell, Ph.D.

Associate Professor Extension Specialist

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn, AL 36849 USA -

Jairo Amezquita

Project Manager of Aquaculture Utilization for the Americas Region

United States Soybean Export Council (USSEC) – Latin America

Cali, Colombia -

-

Herbert Quintero, Ph.D.

Corresponding author

Extension Aquaculture Specialist

University of Arkansas at Pine Bluff (UAPB)

Lonoke Fish Disease Diagnostic Laboratory

Lonoke Agricultural Center

Lonoke, AR 72086 USA

Tagged With

Related Posts

Health & Welfare

Chemical treatment costs reduced with in-pond raceway systems

By dividing ponds into smaller, more controllable areas, IPRS can substantially reduce chemical treatment costs, improve treatment delivery and allow new treatments that are cost-prohibitive in traditional pond settings.

Intelligence

Commercial implementation of in-pond raceway system

An in-pond raceway system in Alabama was utilized to supply various niche markets, including Asian grocery store chains that desired fresh live fish, recreational pond stocking businesses, private pond owners and fee fishing operations. In many cases, a higher price was achieved.

Innovation & Investment

GOAL 2016 preview: IPA technology catching on in China

Intensive pond aquaculture (IPA) technology, a floating, in-pond raceway system developed in the United States, is being adopted fast in China, just three years after its introduction, says Jim Zhang, aquaculture program manager for USSEC-China.

Responsibility

The promise of In-Pond Raceway Systems, part 1

A promising strategy to increase fish production in static aquaculture ponds, the In-Pond Raceway System (IPRS) grows fish confined at high densities in floating or fixed raceways, instead of the animals being free in the pond.