Universities, industry both making strides in closed-cycle aquaculture

Prized for its high fat content, bluefin tuna are perhaps the most prized fish in the ocean. In the modern sushi industry, hon-maguro’spopularity reigns supreme, as many consumers admire its fresh red flesh, one raw bite-sized cut at a time.

This fondness for bluefin, particularly in Japan, has triggered a crisis: Overfishing over the past few decades has drastically reduced populations, and a new stock assessment showed Pacific bluefin at just 3.3 percent of its unfished level, confirming the species’ severely depleted status (number reflects data from 2016, the most recent year available).

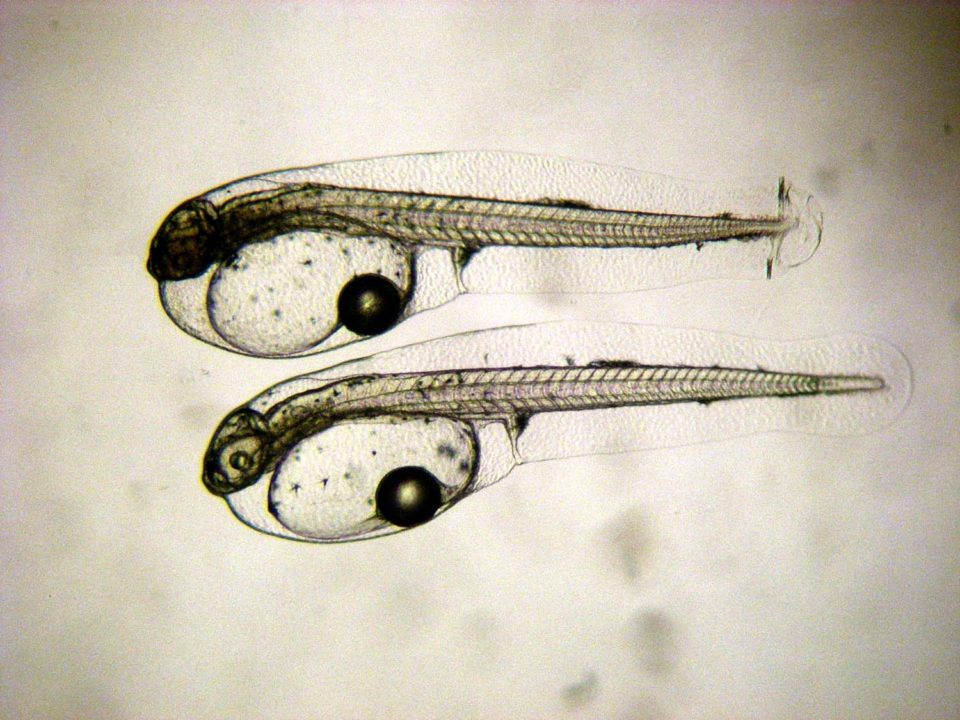

If sashimi is to remain chic, closed-cycle aquaculture may be the key to the species future on menus. In Japan, Kindai University began exploring this possibility in the 1970s by collecting eggs from captive adult fish and artificially inseminating them. They then waited for the eggs to hatch into larvae that they could raise to maturity. Once the larvae became adults and laid eggs, the process would be repeated to produce full-cycle farmed fish.

But efforts were not successful straight away.

“It took 32 years from the beginning of our research into Pacific bluefin farming,” said Prof. Yoshifumi Sawada, director of the Oshima Branch of Kindai University’s Aquaculture Research Institute. “We started our tuna aquaculture project in 1970. In 1974, we successfully reared wild-caught juveniles in offshore cages. In 1979, those juveniles matured and spawned, marking the world’s first spawning of large tuna species under captive conditions. But then, our artificially hatched fish died in 1979, 1980 and 1982. From 1983 to 1993, no spawning occurred at all.”

Eventually, in 2002 Kindai made a breakthrough, producing the world’s first generation of fully farmed Pacific bluefin using the fertilized eggs of artificially hatched, farm-raised parents. The latest generation was produced in 2012.

Seafood firms in Japan have also entered the tuna farming business. Maruha Nichiro, a private company based in Tokyo, began farming bluefin in 1987 but no significant progress was made until the work was discontinued in 1997. But in 2006, with wild bluefin stocks still declining, Maruha Nichiro started again and closed the cycle in 2010. The company’s first commercial shipment of farmed bluefin was made to the private business sector in 2015. A new aquaculture site has also been opened for hatchery-reared juveniles in Oita Prefecture, southern Japan.

“After natural spawning and fertilization in our lab, we scoop the fertilized eggs and hatch them in an indoor facility for about a month until the fish are 2 inches long,” said Hiroyuki Metoki of Maruha Nichiro’s Investors Relations & Public Relations Department. “At this stage, we move them to our ocean site and farm them for about 3.5 years until marketing. This time period can change, however, depending on environmental conditions, such as sea temperature.”

In fiscal 2017, Maruha Nichiro sold around 66,000 bluefin. Of this, 5,000, or around 8 percent of the total, had been reared under closed-cycle aquaculture. The company is now looking to increase these figures so that by 2021, it sells 78,000 bluefin, of which 15,000 will come from closed-cycle aquaculture. Maruha Nichiro is now preparing to export outside Japan, starting with Europe, where Japanese cuisine is becoming increasingly popular.

“What we’re aiming for now is to increase the ratio of closed-cycle fish that we ship, to 19 percent by 2021,” said Metoki. “As our technology improves and we become more experienced, we would like this figure to reach 100 percent. After all, zero percent usage of wild juveniles means zero pressure on wild bluefin stocks.”

Closed-cycle aquaculture may sound promising, but handling bluefin in aquaculture farms is notoriously difficult. As well as being extremely sensitive to stimuli like light, temperature and noise, bluefin are fast swimmers. If upset, they can reach speeds of up to 40 kilometers per hour (25 mph), swimming into nets and dying on impact. Spawning is also unpredictable.

Additionally, feed sustainability questions exist due to the vast amounts of feed that bluefin require. According to Metoki, a majority of the tuna’s feed is “natural fish,” or residua from mackerel canneries in the company’s supply chain that is not intended for human consumption. A shift to moist pellets and extruded pellets, with which they have recorded much lower feed-conversion ratios (FCR), is currently under way. Metoki estimated the FCR, using extruded pellets, at 3.6 to 1.

However, Prof. Sawada believes that Kindai’s technology can make a difference in relieving dwindling bluefin stocks.

“Following Kindai, Japanese firms such as Maruha Nichiro and Nissui have successfully closed the life cycle of bluefin,” he said. “In Spain, the lifecycle of Atlantic bluefin was completed in 2016. Our technology can be duplicated. Japan is closely complying with the restrictions that are in place on catching wild juveniles, including tuna fingerlings, that weigh less than 30 kg, and our full-cycle culture technology is decreasing fishing pressure on bluefin because it provides a stable supply of fish without depending on stocks in the wild.”

Hiroyuki Metoki is also enthusiastic, but says there is still a long way to go in terms of feed efficiency, advanced nutrition and selective breeding, which he added has not yet been successful with bluefin.

“This could be a possibility for us one day but we still have lots of things to learn,” he said.

Follow the Advocate on Twitter @GAA_Advocate

Author

-

Bonnie Waycott

Bonnie Waycott is a freelance writer specializing in aquaculture development and fisheries management, with a particular focus on Japan. She has a keen interest in the recovery of aquaculture in Tohoku, following the Great East Japan Earthquake and Tsunami of March 2011.

Tagged With

Related Posts

Aquafeeds

It takes guts to advance sustainability in aquaculture

With byproducts representing between 25 to 50 percent of the weight of various fish species, we need to be looking at how the entire fish is being used: even the heads, guts and skin.

Innovation & Investment

Tuna aquaculture: Fishing for progress

Aquaculture could be a sustainable alternative to fishing for tuna but achieving commercial-scale production has proven challenging.

Intelligence

Public opinions pose barriers for tuna consumption

Safety and sustainability are key concepts affecting consumers’ decisions on tuna consumption. Although the benefits of consumption exceed the potential negative effects, tuna’s harmful attributes tend to negatively impact purchasing in at-risk groups.

Intelligence

Global finfish production review and forecast: Nearly doubled in a decade

Farmed finfish production has more than doubled since 2005 to an expected 38 million metric tons in 2018; 2019 production is expected to remain at 38 million metric tons.