RAS research at Virginia Seafood Agricultural Research and Extension Center

Over the past few years, interest in commercial production of cobia (Rachycentron canadum) has grown steadily. This species possesses a number of characteristics that make it a natural choice for aquaculture, including impressive growth rates and feed efficiency, promising hatchery production and its highly regarded flesh.

While global production of cobia is currently dominated by Southeast Asian countries, increased market demand and a growing seafood trade deficit are spurring further research and commercial investment in the United States. With the further growth of cobia aquaculture, production techniques that facilitate the farming of this species in an environmentally and economically sustainable manner need to be explored.

To this end, the authors’ group at the Virginia Tech Aquaculture Research Group collaborated with MariCal, an animal health and nutrition company located in Portland, Maine, to examine the commercial feasibility of culturing cobia in recirculating aquaculture systems under low-salinity conditions. Successful implementation of this technology could potentially result in economic benefits for producers of marine finfish.

Benefits of low-salinity culture

Perhaps the most obvious and exciting benefit of culturing marine fish under low-salinity conditions is the reduced reliance upon coastal properties for the siting of production facilities. Production facilities could be built away from delicate and storm-prone coastal ecosystems to strategically selected inland locations that are close to market centers yet have affordable property costs.

In addition, effluents from inland low-salinity production would largely be suitable for treatment by traditional municipal waste water systems. This could decrease both capital and operating costs by reducing the need for on-site treatment facilities.

Furthermore, the establishment of biosecure and/or specific pathogen-free (SPF) stocks would be facilitated, as the use of natural seawater could be reduced or even eliminated from the production cycle. The development of SPF stocks would be of particular interest to those looking to stock disease-free juveniles in net pens or other more traditional marine culture facilities.

Physiology, osmoregulation

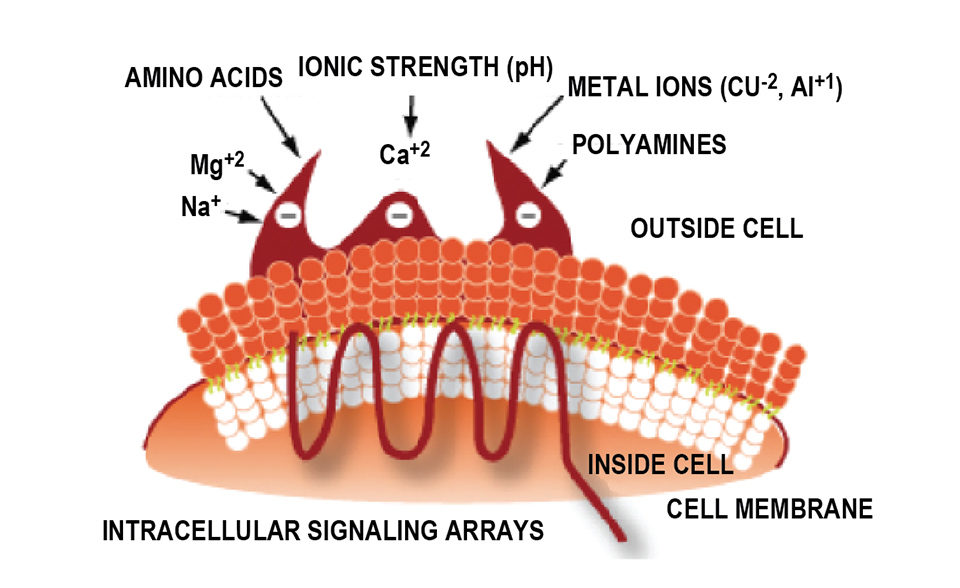

The feasibility of low-salinity culture has been demonstrated for various marine species, such as red drum and marine shrimp. The current approach, however, represents a novel understanding of the physiological processes involved in osmoregulation and growth in fish. This technology is based upon a patented group of proteins called calcium-sensing receptors. These extracellular receptors, which were discovered by researchers at MariCal, allow cells to sense and respond to calcium, magnesium, and sodium ions; and amino acid nutrients in the environment.

The calcium receptors, which are natural components of cells found in various organs of many species, “sense” salt ions in water and are responsible for enabling fish and other aquatic organisms to respond to changes in both water salinity and nutrients in their aquatic environments. By using very specific salt blends in the water and diets, these receptors can be “turned on,” resulting in certain cellular pathways operating as though the fish were in full-strength seawater.

The technology allows marine fish to adapt and grow in very low-salinity environments without the use of genetic modification, drugs, or hormones. Through the use of calcium receptors, specific ionic ratios are maintained in the water and feed that allow cobia to physiologically adapt and thrive under these conditions.

Commercial reality

In 2006, MariCal entered a partnership with Blue Ridge Aquaculture of Martinsville, Virginia, the largest producer of tilapia in the U.S., to design and build Virginia Cobia Farms (VCF). VCF is the world’s first fish farm dedicated to the commercial production of cobia under low-salinity conditions. Located in Saltville, Virginia, VCF hopes to revolutionize the way marine fish are farmed, while providing a fully secure and traceable product raised in recirculating systems with minimal environmental impact. The site in Saltville was chosen due to the region’s affordable utilities, abundance of natural mineral deposits, and proximity to the U.S. Midwest, Southeast, and Gulf states.

Another driving factor was the proximity of Virginia Polytechnic Institute and State University, and its research staff, who are leaders in cobia research and seafood-processing technology. With their initial harvest scheduled for early June, VCF plans to systematically increase production to around 45,000 metric tons per year by establishing a fully integrated production model. This will lead to the establishment of approximately 60 jobs in the economically depressed region surrounding Saltville.

Moving forward

Through collaboration with Virginia Tech Aquaculture Research Group, MariCal and VCF continue to refine and optimize their processes. Building off initial successes, researchers have identified areas of research that will be prioritized over the coming months in an attempt to increase the operating efficiency and economic feasibility of low-salinity production.

Through previous work, it became clear that there are strong genetic and nutritional components involved with maximizing growth and survival under low-salinity conditions. Thus work is currently under way at the Virginia Tech Aquaculture Center (VTAC) to identify the genetic markers that facilitate selective breeding. Additional research at VTAC focuses on examination of ideal energy:protein levels for the creation of phase-specific production diets with an emphasis on utilizing alternatives to traditional fish oil and fishmeal ingredients.

Studies at the Virginia Seafood Agricultural Research and Extension Center are focused on production of cobia fry and fingerlings under low- and manipulated salinity regimes. Work will also begin this summer on a broodstock acquisition and development program. This effort will take the initial steps toward building a population of selectively bred cobia broodstock.

Based on the successes experienced in the laboratory and commercial environments, it is expected that a low-salinity approach will eventually be applied to other high-value marine species and hopefully change the way we look at aquaculture.

(Editor’s Note: This article was originally published in the July/August 2007 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Brendan C. Delbos

Virginia Tech Aquaculture Research Group

Virginia Seafood Agricultural Research and Extension Center

102 South King Street

Hampton, Virginia 23669 USA -

D. Russell

Virginia Tech Aquaculture Research Group

Virginia Seafood Agricultural Research and Extension Center

102 South King Street

Hampton, Virginia 23669 USA -

M.H. Schwarz, Ph.D.

Virginia Tech Aquaculture Research Group

Virginia Seafood Agricultural Research and Extension Center

102 South King Street

Hampton, Virginia 23669 USA -

S.R. Craig, Ph.D.

Virginia Tech Aquaculture Research Group

Virginia Seafood Agricultural Research and Extension Center

102 South King Street

Hampton, Virginia 23669 USA -

E. McLean, Ph.D.

Virginia Tech Aquaculture Research Group

Virginia Seafood Agricultural Research and Extension Center

102 South King Street

Hampton, Virginia 23669 USA

Related Posts

Health & Welfare

Low-salinity culture water controls Vibrios in shrimp postlarvae

In a survey of Vibrio concentrations in white shrimp postlarvae at two inland farms, hatchery postlarvae were acclimated in water with salinity reduced from 30 and 5 ppt to 2 ppt at the farms. One farm stocked postlarvae in nursery ponds, and the other stocked directly into grow-out ponds.

Health & Welfare

Low-salinity fish production technology can cut costs, aid biosecurity

Virginia Tech Aquaculture Research Group collaborated with MariCal to examine commercial feasibility of raising cobia in RAS under low-salinity conditions.

Aquafeeds

Alternatives to fishmeal perform well in low-salinity shrimp farm trial

In a white shrimp farm trial in a low-salinity environment, alternatives to fishmeal did not negatively impact the growth, survival or FCR of the shrimp.

Responsibility

Aquaponic system produces red drum, saltwater vegetable species

A project in Florida is studying the feasibility of a marine aquaponic system containing red drum and two native saltwater species. Water that exits the plant raceways is filtered and recirculated to the fish tanks. In tests, sea purslane grew rapidly, while saltwort took almost four months to adapt. The fish exhibited high survival and achieved a feed-conversion ratio of 1.2.