Resilient, non-pressurized units are less sensitive to flow rate variations, clogging, power interruptions

Moving-bed bioreactor technology was first developed in the late 1980s for industrial and domestic wastewater applications. In general, the process uses plastic carriers which are designed with high internal surface area to support microbial growth. The biofilm carrier elements are suspended in the filter vessel and thoroughly mixed throughout the water column using aeration. This technology makes it is possible to treat high waste loads efficiently without problems of clogging.

Low-space bioreactors

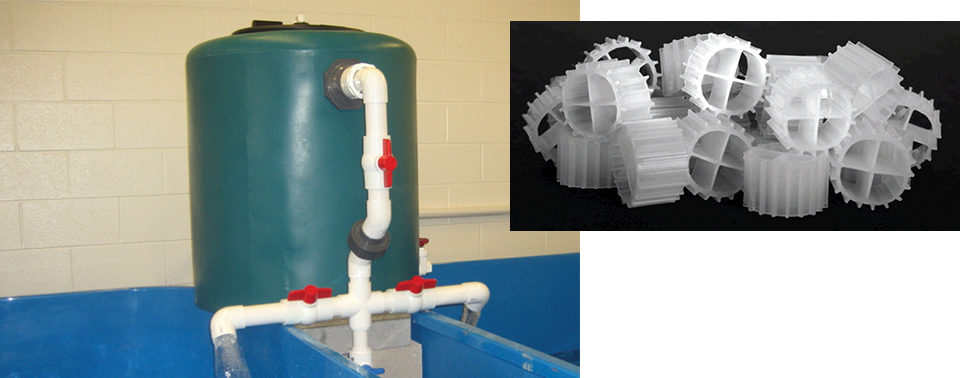

The moving-bed bioreactor design was adapted for aquaculture use in the late 1990s and has proven to be an excellent system for treating ammonia and nitrite. In aquaculture, the system is often referred to as the low-space bioreactor, mainly because of its relatively small footprint.

Low-space bioreactors are resilient, non-pressurized units that are less sensitive to flow rate variations, clogging and power interruptions than other types of biofilters. The bioreactor system is fully automatic, self-adjusting and continuously self-cleaning. It is compatible with low-head recirculating systems and can be installed in many different configurations, including gravity flow in and out of the bioreactor.

When operated in low-head recirculating systems, low-space bioreactors can be sunk into the floor to reduce pump pressure requirements. Less than about 15 cm of head loss are required across the reactors when operated at maximum rated flows.

An aeration grid at the bottom of the bioreactors supplies oxygen to the biofilm. It also provides the mixing energy required to keep the biocarrier elements suspended and completely mixed within the reactors. The air diffuser depth can be adjusted for compatibility with either a blower or compressor.

Because air is used to circulate the media, low-space bioreactors both add oxygen and strip carbon dioxide. For high-density indoor applications, the exit gas should be vented to the outdoors.

Biofilter media

The biofilm carrier media provides surfaces for the growth of the varied bacterial species that convert ammonia to nitrite and ultimately to nitrate in nitrification. Although there are many types of biofilm carriers available today, perhaps the most widely used are three-dimensional, spoked polyethylene disks shaped somewhat like wheels.

With a total surface area of 800 m2/m3 and a protected surface area of 500 m2/m3, this biomedia is ideal for moving-bed applications. The protected surfaces provide a fairly high specific surface area for bacteria growth while still providing room to pass food, oxygen and nutrients for the bacteria. The individual biofilm carrier elements are 7 mm long and 10 mm in diameter.

The plastic media is buoyant and floats for a few days or weeks, depending on the time required to colonize the media. Fluidization improves as bacteria and biofilm grow on the media surfaces.

Best results for the colonizing/fluidizing of new media can be achieved by isolating the biofilter from ultraviolet sterilization, ozone, foam fractionation and chemicals; and making sure the biofilter has enough oxygen (above 60 percent of saturation) with minimal turbulence of the media.

A source of ammonia must be provided, so when establishing a biofilter offline, buffer, micronutrients and ammonium chloride may be needed. Commercial inoculants of nitrifiers are available for improving biofilter colonization and reducing start-up time.

The continuous circulation of the media elements also results in self-cleaning. Over time, the older bacteria are removed from the system, ensuring that the bacteria in the biofilm are always active.

Prefiltration

Low-space bioreactors can tolerate some suspended material. However, if the water being treated is high in suspended solids, there may be an increase in heterotrophic bacteria that outcompetes the nitrifier population. This will reduce biofilter performance and may result in media clogging.

It is therefore important that mechanical filtration is used prior to treatment by low-space bioreactors. In addition, sludge can accumulate over time in the bottom of the bioreactors, especially if the diffusers are raised above the bottom of the filter. To optimize performance, the sludge must be removed periodically.

Design, sizing

Sizing a biofilter can be difficult, as there are many options and parameters to consider. Most aquaculturists recommend oversizing biofilter designs or providing for modules that allow expansion. For large and/or complex applications, an engineer should be consulted.

There are many parameters of concern when sizing a low-space bioreactor, but the most critical are the total ammonia nitrogen (TAN) load for the biofilter, water flow rate, temperature, pH, oxygen concentration and solids prefiltration. Removal rates vary considerably depending on these parameters.

Low-space bioreactors have consistently been shown to have relatively high treatment efficiencies. This is because the media is consistently and evenly moved through the water being treated. The bacteria on the surface of the media are exposed to a steady supply of oxygen and nutrients. Bioreactor performance improves with increased water temperature.

Much of the literature regarding off-the-shelf biofilters suggests that they typically convert TAN at a rate of 0.1-1.0 g TAN/m2 surface area/day. Generally, low-space bioreactors perform within the upper half of this range under warmwater recirculating aquaculture conditions.

(Editor’s Note: This article was originally published in the March/April 2010 print edition of the Global Aquaculture Advocate.)

Author

-

Gary Rogers, Ph.D., P.E.

Vice President of Engineering

Aquatic Habitats Inc.

2395 Apopka Boulevard

Apopka, Florida 32703 USA

Related Posts

Responsibility

Woodchip bioreactors effectively treat aquaculture effluent

Woodchip bioreactors can efficiently remove nitrate, phosphorus and total suspended solids from aquaculture wastewaters. Denitrification treatment of the relatively organic-rich aquaculture wastewater is a new and useful application to protect against water pollution.

Responsibility

Emerging trends in salmonid RAS, part 2

Dozens of land-based, closed-containment salmonid RAS systems are coming on line. New projects are bringing new principles into the salmon industry. Industry expansion hinges upon the development of pollution-mitigating technologies to reduce nutrients in effluents.

Aquafeeds

Evaluating Nannochloropsis-based feeds for tilapia

This study assessed the efficacy and nutritional properties of the marine alga Nannochloropsis salina as a feed ingredient using tilapia (Oreochromis niloticus) as a model species. Results showed adequate growth, survival, FCR and enhanced EPA levels.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.