Advantages and disadvantages of open and closed systems

This article (adapted and summarized from the original publication in Revista Acuacultura – Cámara Nacional de Acuacultura, No. 123, June 2018) describes the different microalgae production systems and their relative advantages and disadvantages. Compared with conventional systems of algae production outdoors, there are clear advantages for the use of closed and controlled systems, but there are still also some technical and economic challenges.

There is a great need for industrial production systems at affordable investment costs. Despite the relatively high costs associated with continuous production equipment currently available in the market, there have been great technological advances that already ensure stable productions, high densities (106 cells/mL) and high nutritional quality.

Microalgae as live feeds

Microalgae have certain characteristics that make them very valuable as a source of live food. Each cell is basically a solar “factory” that synthesizes sugars and other bioactive compounds, which can later be used as nutritional sources, particularly for larval stages of fish and shrimp.

All microalgae are phototrophic, requiring only UV light sources, carbon dioxide (CO2) and inorganic nutrients to grow. The microalgae – being unicellular – have a very simple structure compared to the more advanced plants, and are essentially composed of a cell wall, a vacuole and a nucleus.

This structural simplicity allows for very high rates of growth and reproduction compared to multicellular organisms, because almost all the energy coming from certain wavelengths of light (400 to 700 nm) is used for the synthesis of carbohydrates, proteins and lipids (in this order). This very high efficiency of energy transfer to bioactive molecules makes microalgae an ideal source of nutrition.

Traditionally, natural waters such as lakes and lagoons have been used to grow algae. These open production systems are outdoors and are dependent on the provision of natural light as the only energy source for the system. The main advantage of these open systems is the low level of investment needed to start operations.

However, in general open systems are sensitive to several drawbacks, some more important than others. Contamination by predatory, competitive and/or pathogenic organisms are the most common problems associated with the production of algae in open, outdoor systems.

Additionally, climatic fluctuations, inorganic nutrient flows and an adequate supply of carbon dioxide are other frequent difficulties. Currently, the use of open systems for the commercial production of algae is mostly restricted to situations where axenic conditions are not considered primordial, but low initial investment costs.

In contrast, closed culture systems (bioreactors) are specifically used to grow unicellular organisms under absolutely axenic conditions that guarantee the absence of polluting agents in the crop. The development of photo-bioreactors on industrial scales that can be operated within the feasible biological and economic parameters are still in process. However, during the last two years, the use of medium scale units has shown its benefit in the larviculture sector, particularly in the production of marine and bivalve fish in Europe and in the United States.

Generally, photo-bioreactors are artificially illuminated with Ultraviolet (UV) lamps with specific emission waves within the range of 400 to 700 nm. This type of culture can be located indoors or outdoors, but the former culture conditions are very stable and allow for the maintenance of high densities of cells/mL with homogeneous and optimized nutrient profiles.

Buike, microalgae, Table 1

| Parameter | Open systems | Closed systems |

|---|

Parameter | Open systems | Closed systems |

|---|---|---|

| Contamination risk | High | Very low |

| Carbon dioxide losses | High | Low |

| Evaporation losses | High | Low |

| Light use efficiency | Poor | Excellent |

| Area required | Large | Small |

| Investment costs | Low | High |

| Increasing production | Easy | Difficult |

Open production systems

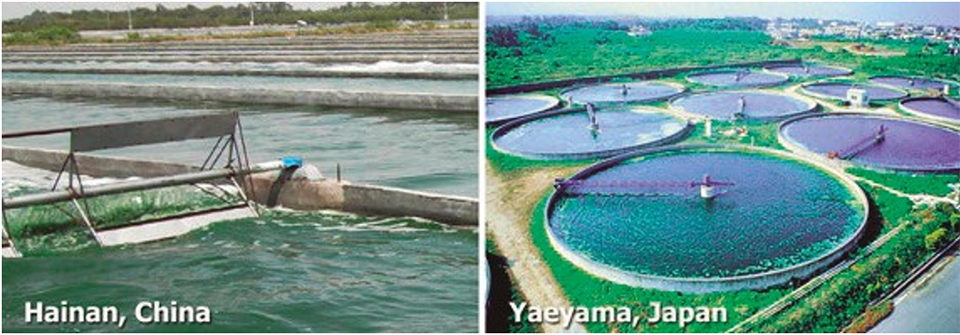

In general terms, open (exposed to the open air) systems represent the classical method of production of unicellular algae biomass, and include artificial pools, tanks and raceways generally operated at depths of 15 to 45 cm and no more than 1 meter.

Various commercial techniques have been used for the production of algae by a number of countries during the last 50 years or so, but currently there is a standardization towards round tanks with axial flows – for greater homogeneity of the crop – and “raceways” with longitudinal flows that are more popular in where physical space is limited.

The open production units offer some advantages, particularly in terms of access to natural light and ease of construction. However, during the last 40 years some significant limitations of this technology have been reported, including:

- To date, only a limited number of microalgae species perform in open systems.

- Open systems require large areas to maintain acceptable area/volume ratios.

- Low efficiency of assimilation of atmospheric carbon dioxide; its supply is almost always the first limiting factor of open systems.

- The maximum production level is much lower than for biodynamic systems in terms of cell density/mL of

- In many cases, the operating costs per kg of biomass harvested are higher in conventional systems due to their higher demand for labor, water and energy.

- Final product quality is variable and very difficult to manipulate.

- Crop contamination by predators, competitors and pathogens is very frequent and costly to resolve; for example, due to system design of tanks used, evaporation losses are high.

Despite several innovations over the years – including temperature control, micronutrient drop delivery, direct carbon dioxide injection and mechanical homogenization equipment – the productivity of these systems remains very low relative to the latest generation of photo-bioreactor systems, giving the latter a clear technical superiority despite their higher cost.

Closed production systems

The production of sufficient quantities of high-quality microalgae free of pollution is a continuing challenge for many of the local larval laboratories, which often results in the use of inferior alternatives or insufficient amounts of algae, and in extreme cases the used of dyed water that does not even contain microalgae.

Traditional, open culture techniques have high demands for labor, space, and air and water supply systems. In situations that demand axenic (free from other living organisms) conditions, the operating costs of increase exponentially. Nowadays we are seeing that the initial advantages of these systems have been overcome by the inherent limitations of open production.

This situation has resulted in the development of commercial scale, closed systems for microalgae production. Many such systems already operate in hatcheries, mainly in Europe and the United States, but there is much potential for the application of this technology in larval production laboratories in our region.

Modern photo-bioreactors

The modern photo-bioreactors (FBRs) allow the total automation of the microalgae production process and yield very high (>106) cells densities per mL of culture of various microalgae with high nutritive quality and with a comparable and sometimes lower operating cost than conventional systems, and completely free of contaminants. In fact, one of the most important advantages of FBRs is the biosecurity they provide, significantly lowering the economic risks of production.

In conventional systems, it has been amply demonstrated that the pathogenic organisms that grow together with the microalgae are transferred directly to the larval cultures, and the depressive effect that certain microspecies exert on Vibrios does not occur, and, in fact, the co-cultivated bacteria and microalgae express a synergy rather than suppression.

“Closed reactors provide a bio-secure environment, reducing the possibility of contamination of the crop. The control over the microbial environment is of the utmost importance, because it impacts survival rate and consequently the profitability of our operation,” according to Pride Farms (Galicia, Spain), commenting on the real benefits provided by photo-bioreaction technology.

Perspectives

For Ecuadorian shrimp hatcheries, the use of technologies for the continuous production of microalgae within a closed and completely controlled environment would directly impact larval quality and volume production. For hatcheries located in areas with high incidence of shrimp diseases and low biosecurity, new closed production technologies could offer a viable alternative despite the relatively high cost of initial investment.

References available from author.

Author

-

Philip Buike

Technical Manager

National Aquaculture Chamber (Cámara Nacional de Acuacultura)

Guayaquil, Ecuador

Tagged With

Related Posts

Health & Welfare

Advances in intensive copepod production technology

Research at the Oceanic Institute has been successful in overcoming bottlenecks associated with rearing small-mouthed fish larvae by finding a suitable first feed. Early work on the calanoid copepod Parvocalanus crassirostris focused on parameters necessary for successful maintenance of stock cultures.

Aquafeeds

Algae alternative: Chlorella studied as protein source in tilapia feeds

Chlorella and other species have potential as protein sources in aquafeeds. In trials with tilapia fry raised in a recirculating system, the fish received a fishmeal-based control diet or feeds with portions of the fishmeal replaced by Chlorella.

Innovation & Investment

Algae innovators aim to freeze out early-stage shrimp losses

A greenhouse in Belgium believes its innovative shrimp feed product, made from freeze-dried microalgae, packs the necessary nutrients for the crustacean’s most vulnerable life stage: the first three days of its life.

Health & Welfare

Algae shows promise as alternative DHA source in rainbow trout diets

A growth trial in Canada evaluated the use of algae biomass to increase the concentration of long-chain polyunsaturated fatty acids in the tissues of rainbow trout.