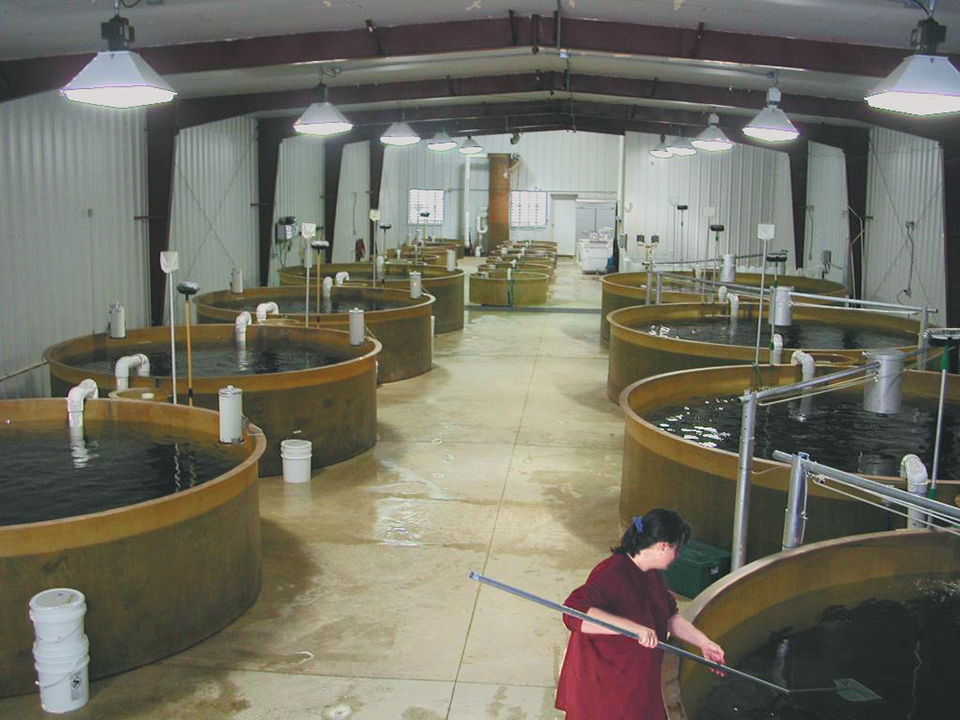

Mingo County Hatchery incorporates a variety of automated water-treatment methodologies

For the better part of a century, the rural Appalachia region of the United States was synonymous with the production of coal. Vast coal mines and miles of railroad created employment opportunities and a chance for a better life for generations of coal workers. But by the 1960s, many of the region’s mines had been exhausted and coal companies began shutting down, leaving once-booming local economies in shambles. In West Virginia, “King Coal” currently employs a scant 2 percent of the workforce. Today, a coal mine at Thacker Fork in Mingo County, West Virginia is once again a valuable resource. Cold, clear water from an abandoned portion of an active coal mine – made to order for hatching Arctic charr eggs spawned in Canada’s Yukon Territory – holds promise for economic relief.

Vision of the future

In 1996, the Mingo County Redevelopment Authority (MCRA), a public West Virginia corporation charged with bringing economic prosperity back to the region, saw a unique opportunity. Globally, the United States is the second-ranked seafood market in dollar value; however, it ranks only 10th in world production. Based on West Virginia’s proximity to the huge East Coast seafood market, MCRA saw this trade deficit as a marketing dream with tremendous potential.

In an attempt to capitalize on the unique opportunity, the agency sought to pair an abundant, yet underused natural resource – discharge water from underground coal mines – with one of the fastest growing segments of the world agricultural economy – aquaculture.

After conducting a survey of potential sites in Mingo County, a suitable site was found. Donation of the land at Thacker Fork to MCRA by the Pocahontas Land Co. and generous in-kind contributions by the Mingo- Logan Coal Co. provided leverage to secure funding from the U.S. Department of Agriculture’s Rural Development Program.

In 1997, the Mingo County Mine Water Demonstration Project was launched to promote the development of cold-water aquaculture in Mingo County and help build the aquaculture technology infrastructure needed to boost the economy of southern West Virginia. A successful charr hatchery was the result.

From conception to reality

MCRA contracted with the Shepherdstown, West Virginia-based Freshwater Institute to find a site with suitable water quality, consistent water flow, road accessibility, and power and telephone services. The Freshwater Institute, an applied research program of the non-profit Conservation Fund, works to develop cost-effective water-conservation technologies that integrate economic development and environmental goals.

In addition to site selection, the Freshwater Institute also designed the hatchery. Relying on water pumped from an inactive mine at Thacker Fork, 0.4 km away, the facility was designed as a flow-through system, but equipped for later conversion to incorporate reuse of water.

Institute engineers made regular site visits and oversaw key aspects of the fish production system construction. They also compiled a comprehensive operating manual and provided hands-on training to employees.

Last June, the hatchery received its first shipment of 150,000 Yukon Gold™ Arctic charr eggs from Icy Waters, International in White Horse, Canada. Another 100,000 eggs were imported from Canada last December. The initial batch of fish will soon be transferred to a growout farm and harvested when they reach about 1.4 kg. With two egg shipments per year, as soon as one group is transferred into the eight, 3.6-meter and 4.6-meter diameter fingerling tanks, the next group will be ponded in six of the 12, 1.2-meter fry tanks.

Mine water study

Fish farming requires plenty of water. In 1994, with a grant from the Appalachian Regional Commission, a federal agency that works to support economic and social development in the area, the Freshwater Institute examined the economic feasibility of using discharge water from abandoned mines in West Virginia as inputs for aquaculture.

Although more typically thought of as a potential liability than as an asset or resource, mine water is an abundant commodity in the state. While some of the discharge – especially in the northern part of the state – is highly acidic or contains elevated levels of undesirable elements such as aluminum or iron, mine water in southern West Virginia is generally clear, drinkable, free of fish pathogens, and cold enough to grow Arctic charr.

Some of the water sources identified by the Freshwater Institute in its site search were overflowing from abandoned mine portals, while other discharges were pumped from inactive portions of mines to prevent water levels from flooding active mine areas. From these, a suitable pumped mine-dewatering discharge was identified.

Several years of pumping records supplied by the site owner, the Mingo-Logan Coal Co., indicated that more than 3,785 liters per minute was annually pumped from the mine water pooled within the inactive portion of the coal mine. To produce a continuous 3,000 liters per minute flow for the hatchery, the coal company installed a new pump in the lower end of the mine pool, which was estimated to contain hundreds of millions of liters of water.

Pretreating mine water

To prepare the mine dewatering discharge for use in the fish hatchery required the stripping of excess dissolved carbon dioxide and nitrogen gases. The discharge water contained 40-80 milligrams per liter of dissolved carbon dioxide, a result of the water’s high alkalinity (about 400 milligrams per liter as calcium carbonate). Also, a severe dissolved-nitrogen saturation problem could occur if the mine dewatering pump suctioned air into its pump intake along with the water.

To prevent dangerous levels of dissolved gases from entering the hatchery, a counter-current cascade stripping column was designed in the top of a water-surge tank installed directly uphill from the hatchery building. This stripping column has successfully maintained the dissolved carbon dioxide at levels below 20 milligrams per liter, while also stripping excess dissolved nitrogen from the water supplied to the hatchery.

Additionally, an unpressurized oxygen column and lowhead oxygenator were installed within the hatchery building to treat the water before it enters the fry and fingerling tanks, respectively. These columns are designed to drive out dissolved nitrogen to below saturation levels, while adding dissolved oxygen to levels 20 to 100 percent above saturation.

Wastewater treatment

Each fry and fingerling tank is plumbed with a drain sump containing two standpipes, which allows the flow to be discharged to two separate locations. The culture tanks discharge the major portion of their water to a pipeline installed in the floor trenches. These pipelines carry the flow to the microscreen drum filter before discharge.

On occasions when tanks are disinfected or when fish are treated with chemotherapeutants, water leaving each culture tank can be directed through a second standpipe to a floor trench, where the flow is then carried to an offline catchment basin. Cleaning water from washing down and disinfecting the floors is also directed into the floor trenches and carried to the catch basin.

The waste collected on the microscreen filter, which consists of fish manure and waste feed, is automatically backwashed from the sieve panels. The backwash flow only amounts to about 19 liters per minute, and the manure is captured within a storage tank outside the hatchery building. Nearby land-restoration projects welcome the application of the manure as a soil amendment.

Public/private partnership

Upon completion of the hatchery, private investors expressed an interest in managing the facility and capitalizing future expansion. Under a leasehold agreement, West Virginia Aqua LLC – a consortium of local mining and land companies – now operates the hatchery, although MCRA retains ownership. Currently, the hatchery employs a fulltime manager and two technicians.

With additional investment, the hatchery’s annual production capacity is expected to reach 500,000 to 1 million fingerlings, depending upon the size of the fish when harvested. The potential exists to produce up to 1,500 metric tons (MT) of foodfish annually.

Earlier this year, West Virginia Aqua began construction of a U.S. $1.9 million commercial growout facility in Man, West Virginia. The grow-out farm was designed by Canadian firms PRAqua Technologies Ltd. and JLH Consulting Inc. based on the cold-water recirculating technology developed at the Freshwater Institute.

This growout farm will also use mine water while producing some 180 to 225 MT of fish each year. Mike Lawrance, general manager for West Virginia Aqua, is looking ahead and hopes to expand operations with additional Arctic charr grow-out farms, each supplied with fingerlings produced by the MCRA hatchery.

Arctic charr (Salvelinus alpinus), a North American relative of the brook trout, shares the subtle flavor traits of trout and salmon. The commercial culture of the fish is still in its infancy in the United States, and charr therefore is considered a specialty item, warranting a higher market price than other commercial salmonids. In recent years, production has increased, yet farmed charr has remained consistently higher in price, due in large part to its lack of susceptibility to the seasonal harvest cycles and price fluctuations of wild-caught salmonids.

Conclusion

Abandoned mine sites are a significantly underused resource in rural West Virginia and the Appalachian region. But projects like the Mingo hatchery are proving that with responsible planning, mine lands can once again be productive. They possess the potential to help the area diversify its economy, allowing rural communities once solely dependent on coal to become self-sufficient participants in the world economy.

It is anticipated the success of the Mingo hatchery will spur replication of the unique post-mining land use. Environmental responsibility, an inherent element of the Mingo project, is crucial to the long-term success of such natural resource-based businesses. The design of the Mingo County Hatchery incorporates a variety of automated water-treatment methodologies to reduce water usage, control water quality, and reduce effluent discharge into Thacker Fork.

(Editor’s Note: This article was originally published in the June 2001 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Jo Ann Simmons

The Conservation Fund

Freshwater Institute

Shepherdstown, West Virginia, USA -

Steven T. Summerfelt, Ph.D.

The Conservation Fund

Freshwater Institute

Shepherdstown, West Virginia, USA -

Tagged With

Related Posts

Innovation & Investment

Matorka aims to unearth innovation with Arctic charr

A new and ambitious Iceland company is about to construct what it claims will be the world’s largest land-based salmonid farm. What sets Matorka’s Arctic char farm apart is its ability to tap into natural resources unique to the island nation.

Health & Welfare

Off-flavors in salmonids raised in RAS

The presence of compounds such as geosmin and 2-methylisoborneol (MIB) in recirculating aquaculture systems (RAS) can result in earthy or musty off-flavors in salmonids raised in the systems.

Intelligence

Quantifying temporal changes of selected fatty acids in fish

Study quantifies temporal changes of selected fatty acids from six fish species subjected to two handling and three storage methods compared to samples that were processed immediately.

Intelligence

City fish-farm prototype set to prove itself in Minnesota

The Urban Organics model of farming leafy greens in conjunction with fish can work in any city environment, the company says. The first step is destroying East St. Paul’s image as a food desert.