USSEC: IPA technology can help meet the demand for increased, sustainable aquaculture production

An in-pond raceway system to intensify and gain efficiency in pond fish production was successfully demonstrated in China in 2013 by the international marketing program of the U.S. Soybean Export Council (USSEC). This intensive pond aquaculture (IPA) technology was developed in the United States as a means to increase the productivity of aquaculture in existing pond units by culturing fish in aerated raceways within ponds and removing solid wastes. Removal of the solid wastes allows a threefold or greater increase in fish production over traditional pond culture technologies.

The technology was transferred to China by USSEC through a cooperative project funded by the Iowa Soybean Association and the Wujiang Municipal Aquaculture Co. Ltd. (Wujiang), with technical guidance from Dr. Jesse Chappell of Auburn University. Pentair Aquatic Eco-Systems has a license for this technology and will be commercializing it in 2014.

Addressing constraints

The IPA system was selected for demonstration in China as a means to address the increasing demand for aquaculture products in the face of mounting economic and environmental constraints to the growth of Chinese aquaculture production. These constraints include rising land values and increasing pond rental costs that require greater economic return from fish farms, limited water availability and declining water quality issues, and increasing food safety concerns.

With no land area to expand aquaculture production in China, intensification of production in existing fish ponds is needed to address these constraints and ensure the economic sustainability of the industry. The IPA technology addresses these constraints by allowing greater management control that yields greater fish production at lower per-unit cost through improved fish survival and feed conversion. The zero-exchange system captures nutrients for use as a crop fertilizer and requires minimal use of drugs and chemicals to ensure food safety.

Wujiang IPA system

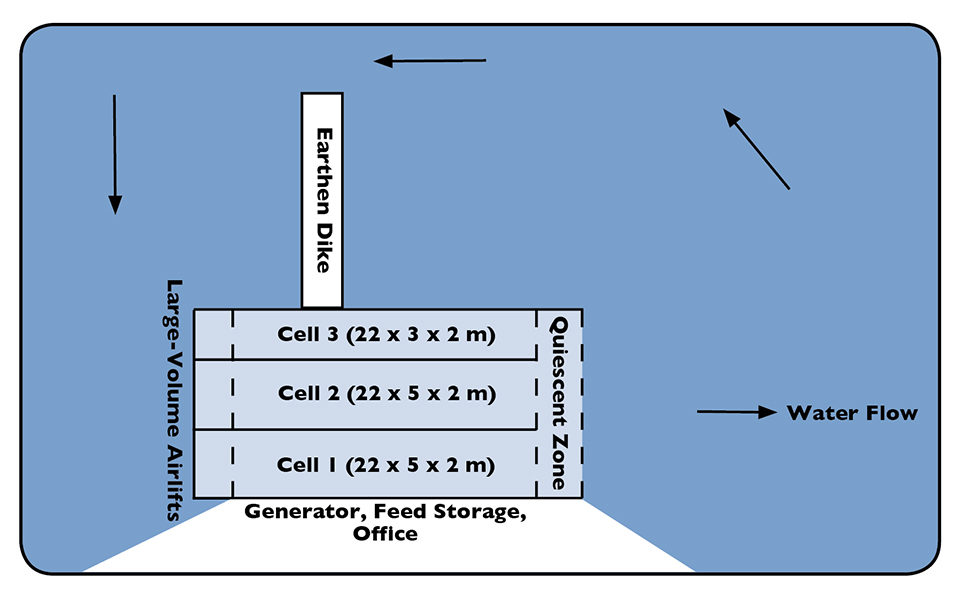

The model IPA system was constructed at the Wujiang fish farm in Jiangsu Province, China, in early 2013. The Wujiang IPA system consists of three concrete raceway cells constructed within a 2.1-ha fish pond. The raceways are 22 meters in length, with two of the raceways 5 meters in width and one raceway 3 meters in width. The average water depth in the three raceway units is 1.5 meters. A 13- x 3-meter quiescent zone was constructed at the downstream end of the raceways for solid waste settling and removal.

The raceways were designed to culture larger fish in the two larger raceways and fingerlings in the 3-meter-wide raceway. At the head of each raceway, a high-volume air blower supplies air to diffuser mats at the bottom, creating an airlift system that lifts water that is deflected by a stainless steel hood to create a constant water current through each raceway cell. The pond is subdivided by an earthen dike to allow full circulation of the water flowing through the raceways and around the pond before reentering the raceways.

Grass carp were selected as the initial test species for the Wujiang IPA system. Grass carp are the leading fed fish species in China, with 4.78 million metric tons (MT) cultured in 2012. The Wujiang fish farm was selected based on its designation as a national grass carp research and demonstration unit and the farm’s previous work in demonstrating USSEC’s 80:20 pond technology.

IPA cells 1 and 2 of the IPA system were stocked with 750-gram and 300-gram grass carp, respectively, in mid-May 2013. IPA cell 3 was stocked with 4-gram grass carp in July 2013. Grass carp in all three cells were fed four to five times daily from the time of stocking until harvesting in November 2013.

The carp in cells 1 and 2 were fed with a USSEC 32/3 grass carp diet for the duration of the feeding demonstration. USSEC feeds are identified by their protein and lipid contents, so the 32/3 feed had 32 percent crude protein and 3 percent crude lipid. Grass carp in cell 3 received USSEC 36/7 feed from a fish size of 4 grams to 50 grams, after which they were fed the USSEC 32/3 feed. Both the 32/3 and 36/7 feeds were least-cost formulated and contained over 40 percent soybean meal as the primary protein source.

Solid wastes were collected two or three times daily by vacuuming from the quiescent zone. The culture cells were periodically disinfected with approved chemicals for disease control. Fish were sampled monthly to monitor growth and feed conversion.

Results

The carp in IPA cell 1 were harvested for marketing on November 13, 2013 (Table 1). The 3-year-old grass carp in cell 1 grew from 750 grams to an average weight of 2.6 kg in 182 days with a feed-conversion ratio (FCR) of 1.89. The total fish harvest weight from the 22- x 5-meter cell was nearly 22.5 MT. The grass carp survival rate was 98.5 percent.

The fish in cell 2 were transferred to cell 1 for further grow-out. The estimated fish production from cell 2 was 15.8 MT, with the grass carp growing from 300 grams to 1.7 kg in 182 days (Table 1). Average fish survival was estimated as 98.1 percent with an FCR of 1.48.

Cremer, Stocking and harvest data, Table 1

| Cell 1 | Cell 2 | Cell 3 | |

|---|---|---|---|

| Cell dimensions/water volume (m3) | 22 m x 5 m | 22 m x 5 m | 22 m x 3 m |

| 176 m3 | 176 m3 | 105 m3 | |

| Fish stocking size (g) | 750.0 | 300.0 | 4.1 |

| Stocking density (fish/m3) | 53 | 59 | 303 |

| Fish stocked | 8,732 | 9,687 | 30,000 |

| Total stocking weight (kg) | 6,549 | 2,906 | 123 |

| Total harvest weight (kg) | 22,483 | 15,775 | 3,748 |

| Average fish harvest weight (g) | 2,614 | 1,660 | 150 |

| Fish survival (%) | 98.5 | 98.1 | 83.3 |

| Feed-conversion ratio | 1.89 | 1.48 | 0.56 |

| Culture period (days) | 182 | 182 | 120 |

| Average daily gain (g) | 10.24 | 7.47 | 1.22 |

Carp in IPA cell 3 were transferred to cell 2 for further grow-out. Estimated fish production from this cell was 3.7 MT, with grass carp growing from 4 g to 150 grams from mid-July to mid-November (Table 1). The estimated fish survival was 83.3 percent. The estimated FCR for the fish raised on the combination of USSEC 36/7 and 32/3 soy-based feeds was 0.56.

Perspectives

The Wujiang IPA feeding demonstration yielded a total production of 42 MT of grass carp from the 2.1-hectare (ha) pond unit containing three IPA raceway cells. This represented nearly three times the average pond yield of 7.2 MT/ha obtained in the 2.57 million ha of fish ponds currently operated in China. The success of the initial USSEC IPA feeding demonstration showed that the IPA technology can help meet the demand for increased, sustainable aquaculture production in China.

(Editor’s Note: This article was originally published in the January/February 2014 print edition of the Global Aquaculture Advocate.)

Authors

-

Michael Cremer, Ph.D.

International Aquaculture Senior Program Advisor

U.S. Soybean Export Council

16305 Swingley Ridge Road, Suite 200

Chesterfield, Missouri 63017 USA[103,114,111,46,99,101,115,115,117,64,114,101,109,101,114,99,109]

-

Jesse Chappell, Ph.D.

IPA Technical Advisor

Auburn University

Auburn, Alabama, USA -

Zhang Jian

China Aquaculture Program Manager

U.S. Soybean Export Council -

Zhou Enhua

China Aquaculture Freshwater Technical Manager

U.S. Soybean Export Council

Tagged With

Related Posts

Health & Welfare

A look at tilapia aquaculture in Ghana

Aquaculture in Ghana has overcome its historic fits and starts and is helping to narrow the gap between domestic seafood production and consumption. Production is based on Nile tilapia.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.