Ichthus Unlimited, primarily a fish feed company, brings fresh farming hopes to the ‘Tuna Capital of the World’

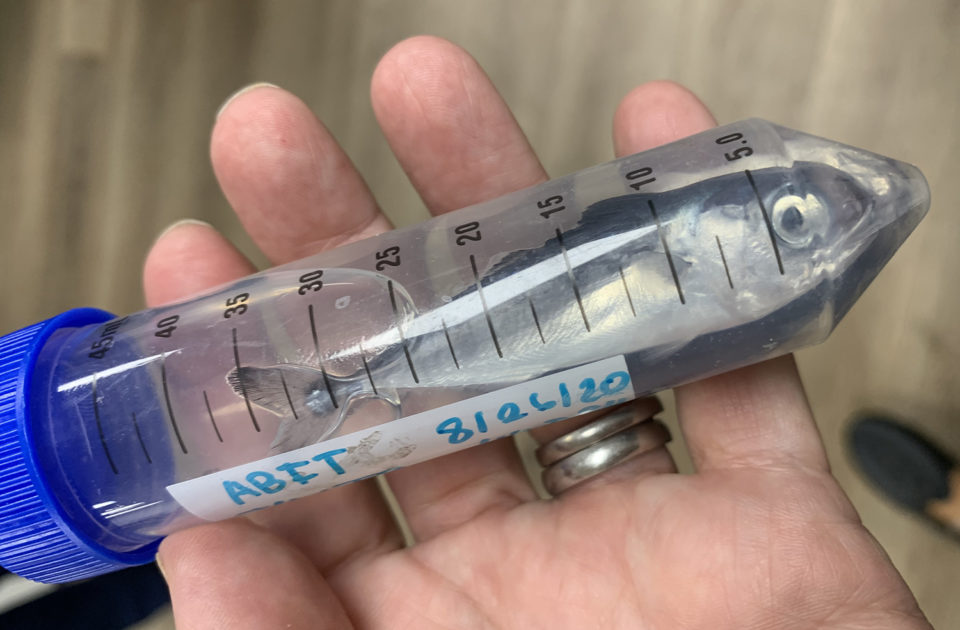

Like a doting father, Alejandro Buentello eagerly shows off the petite 44-day old bluefin tuna swimming and darting in a tidy row of see-through tanks. Getting the first bluefin tuna hatchery in North America up and running has been no small task, and Buentello still has a ways to go before his company, Ichthus Unlimited, reaches its goal of supplying hatchery-raised bluefin tuna for tuna ranchers south of the U.S.-Mexico border.

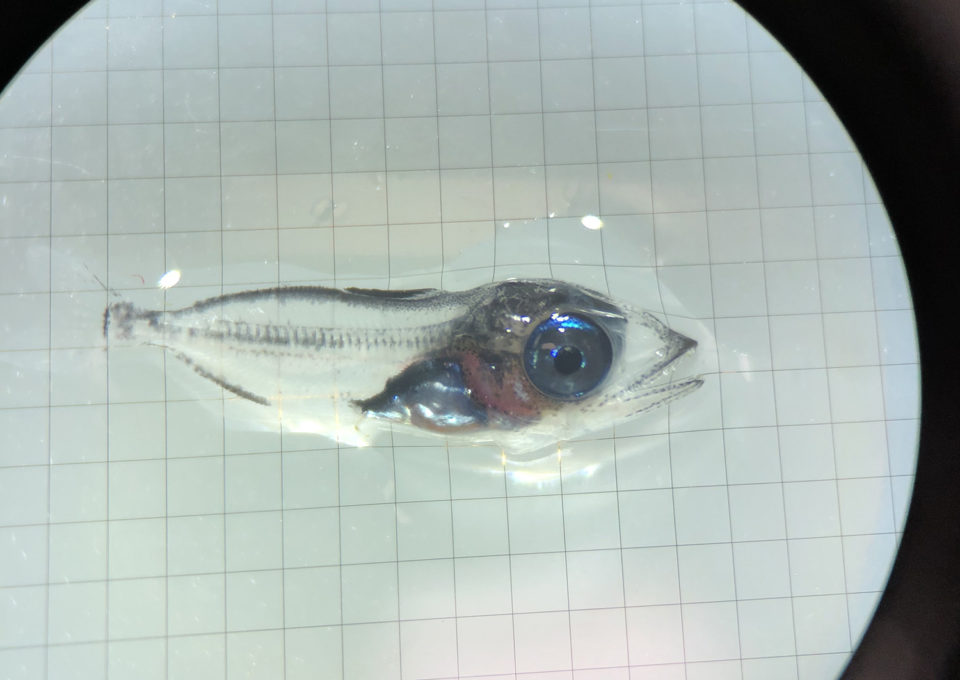

The illuminated tanks are lined up near the wall of the 6,500-square foot San Diego facility. They’re tucked behind a large tarp used to cordon the fish off from the rest of the building in an effort to create an area of calm – an improvised tuna Zen garden. At only 9 cm, the 20 or so Atlantic bluefin tuna inside each tank are sensitive to loud noises, which can cause them to startle and careen into the walls of the Japanese-designed systems.

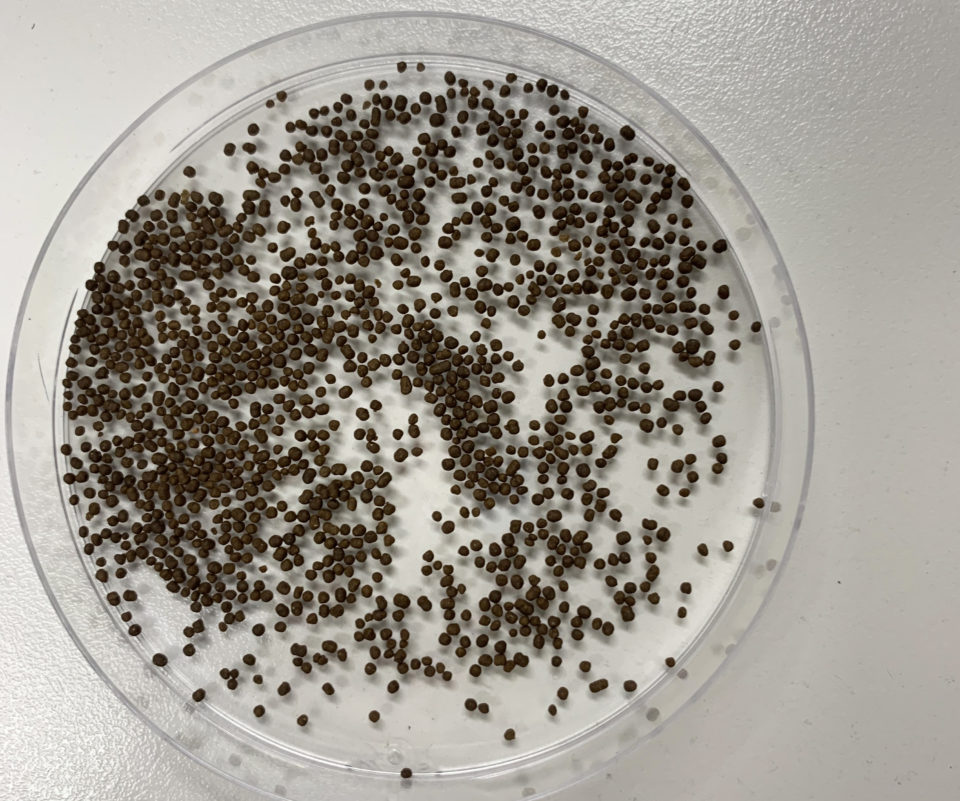

Mariana Michelato Kawakami, Ichthus Unlimited’s project manager, gently taps a vial of tiny-sized pellets of feed into each tank, watching as the months-old tuna snap them up.

Bringing bluefin tuna aquaculture to a city once deemed “The Tuna Capital of the World” may seem a risky bet in a time where the pandemic has shuttered restaurants around the globe; as NOAA Fisheries pleads with tuna fishermen to secure buyers before fishing for the prized fish over concerns of sagging sales; and emerging cell-based seafood companies like San Diego-based BlueNalu or Bay area Finless Foods have set their sights on growing the premium product in labs. But Buentello insists the future looks bright for bluefin tuna aquaculture, emphasizing that Ichthus Unlimited is first and foremost a feed company.

With a typical feed conversion ratio (FCR) of around 20:1 (pounds of baitfish required to grow 1 pound of tuna), keeping ranched bluefin fed has been notoriously expensive. Mexican tuna ranches rely on nearby Pacific sardine populations to fatten the fish, and when unavailable, turn to frozen supplies of herring – from areas like New England, Norway, the Baltic Sea and elsewhere – which can carry an added pathogen risk. Throw in less-than robust wild bluefin stocks available to harvest for ranching, and the path to success remain steep.

Buentello is betting that the solution will come in the form of a feed breakthrough and is aiming for aquaculture’s holy grail: a true fishmeal replacement.

“It doesn’t make sense that we increase the number of tuna [farms] if the resources aren’t here to support them,” he told the Advocate. “But if we provide sustainable feed and produce juveniles to reduce fishing pressure, the bottleneck of the species is resolved.”

Funded in part by grants from the Foundation for Food and Agriculture Research and the Illinois Soybean Association, the feed side of the business is called NutriTuna. Extruded pellets are moist and designed to float, both to help create a desired feeding frenzy by the tuna at the surface of pens – allowing growers a chance to visually see and assess the health of the fish – and to curb loss from hovering birds and marine mammals. The pellet’s buoyancy also allows staff to retrieve uneaten pellets for later use.

“For us, that’s money in the water,” said Buentello.

Ichthus Unlimited’s proprietary feed has reduced the FCR to an impressive 4:1 ratio; is MSC-certified; helps reduce mercury levels in the final tuna product – a top concern among consumers; and increases the shelf life while maintaining desired texture and color.

Should Buentello succeed on the hatchery side of the business, ApexFish, it would mean nearby ranches in Baja California (and perhaps any future ranches in the United States) would no longer have to solely rely on rounding up wild tuna to fatten. Instead, farms could turn to hatchery-raised juveniles already accustomed to eating pellets, along with the feed specifically developed for them. (While this first batch of juveniles are from Atlantic bluefin stocks, Buentello said they will not be placed in Pacific waters. Only Pacific bluefin tuna will be raised for Baja farms or any future restocking efforts in this region.)

Russ Vetter, senior scientist for fisheries, genetics and aquaculture at NOAA’s Southwest Fisheries Science Center has been keeping a close eye on the project.

“The arguments against bluefin tuna farming are that bluefin are sloppy feeders and a lot of the feed is wasted; that a lot of the feed is [made up of] sardines, anchovies and other forage fish that should remain in the ecosystem; that it will never pan out to be profitable or environmentally sustainable. But I think some of those arguments are changing now,” said Vetter. “I’m not convinced it can’t be done.”

But Shana Miller, senior officer, international fisheries conservation for The Ocean Foundation, remains concerned.

“People love to eat wild-caught bluefin, but a number of populations are still severely depleted,” said Miller. “It would be nice to have a replacement for them on the market, but the farmed fish have not proven to be a replacement. Whether you’re growing them from egg or just fattening them from the wild, it’s an expensive operation.

“Bluefin aren’t productive. They’re slow to mature and are long-lived. That’s not the kind of animal you want to farm. You want a species like a skipjack that’s fast-growing and lives to five to 10 years, max. Even yellowfin farming from a biological perspective makes more sense. They’re a much more productive species, faster-growing, earlier maturing.”

But Buentello argues it’s bluefin tuna’s precarious future that makes his work so important.

“This is a multi-culture, multi-country effort – not just us,” he said. “What we are doing here is because there are fewer tuna.”

Follow the Advocate on Twitter @GAA_Advocate

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Clare Leschin-Hoar

California-based journalist Clare Leschin-Hoar covers food policy and seafood. Her work has appeared in The Guardian, NPR, Scientific American, EatingWell and many more. Follow her on Twitter @c_leschin

Tagged With

Related Posts

Innovation & Investment

Japan hopes aquaculture can save bluefin tuna

Bluefin tuna may be the most prized fish in the ocean. If hon-maguro sashimi is to remain chic, closed-cycle aquaculture may help keep it on menus.

Intelligence

Tuna ranching in Baja California, Mexico

Tuna fleet relocation hurt Ensenada, Mexico. The response was bluefin tuna ranching, in which wild fish are caught and stocked into floating pens where they are fed until market size.

Innovation & Investment

Petri dish to plate: How close is cellular seafood?

Companies growing meat in laboratories need to overcome challenges including cost, regulation and consumer acceptance. Proponents believe there’s a place in the market for lab-grown fish meat.

Innovation & Investment

Tuna aquaculture: Fishing for progress

Aquaculture could be a sustainable alternative to fishing for tuna but achieving commercial-scale production has proven challenging.