Marine sand worms a reliable, bio-secure on-farm source of fatty acids for broodstock

Expansions of the marine prawn- and fish-farming industries in Queensland, Australia, are being limited through stringent wastewater licensing conditions that rightly protect natural environmental values. Such industrial expansions are necessary in the medium to long term for Queensland’s food security, and should also be pursued because of the many social, economic and regional benefits they have demonstrated in the past.

While there is wide recognition that well-managed aquaculture operations can be environmentally benign, the significant intensifications and expansions that are envisaged for this sector will likely require improved wastewater remediation methods that can at least adjust suspended solids and nutrient loads in pond waters back to natural background levels.

PASF

A presentation at the Australian Prawn and Barramundi Farmers Association Annual Conference in Sydney in August provided encouraging results for the upscaling and industrialization of polychaete-assisted sand filter (PASF) technology as a practical way of treating mariculture effluents. The Department of Employment, Economic Development and Innovation in Queensland has been developing the PASF concept since 2005 and is now looking toward its commercial uptake.

In a PASF system, wastewater from marine shrimp and fish farms is passed through a constructed sand bed to remove suspended solids, algae and organic debris. Polychaete worms are cultured in the sand bed to help stop the bed from clogging and to produce a profitable by-product. Perinereis helleri, an intertidal Nereidid worm found locally in Moreton Bay and throughout the Indo-Pacific, became the focus of present investigations after showing better attributes than a range of other species.

The worms are harvested at the end of the prawn or fish crop and used for bait or feed for shrimp and fish broodstock. As bait, they represent a sustainable source that avoids the disturbances digging wild worms has on natural populations and environments like seagrass meadows. As broodstock feeds, they provide a reliable, bio-secure on-farm source of fatty acids and other nutrients that are essential for high performance of shrimp and fish spawners.

Initial research

The initial small-scale trials showed that the presence of these polychaetes in simple down-flow sand filtration beds helped to clear the organic debris that would otherwise block the sand and stop the percolation of water. This meant there was no need to regularly backflush the filters and that larger-scale applications could treat large volumes of water. The polychaetes were shown to lower the amounts of organic matter in the upper layers of the sand filter and increase percolation rates through the filter.

Total suspended solids (TSS) and chlorophyll a levels were consistently reduced over 50 percent by the filtration process, and nutrients were converted into bioavailable dissolved forms. Worm biomass production during a 16-week operational period was on the order of 300-400 g/m2. The worms were used successfully as broodstock feeds at commercial fish and shrimp hatcheries.

Recent trials

Larger-scale application of the PASF system at three commercial fish or shrimp farms has recently provided even better wastewater treatment results. TSS and chlorophyll a were both removed with a high level of efficacy, but in addition, total nitrogen (T.N.) and total phosphorus (T.P.) were also removed from wastewater at significant levels on a continuous basis.

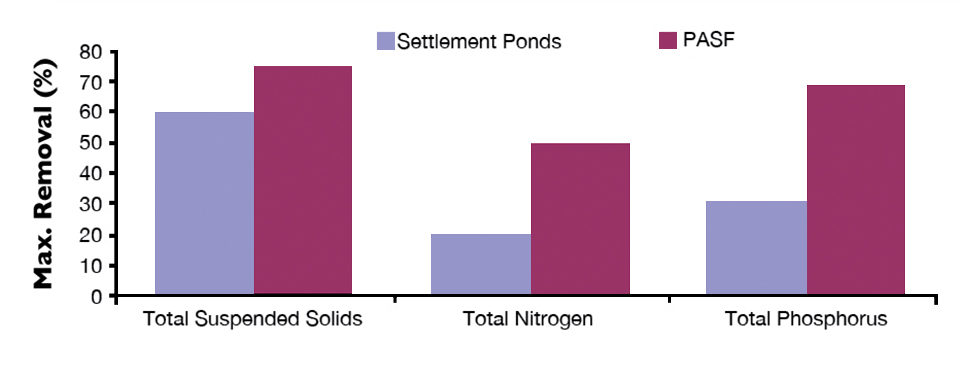

Maximum T.N. and T.P. removals in the trial were 48.8 percent and 67.5 percent, respectively. Average removals at the three farms ranged from 20.0 to 27.7 percent for T.N. and from 22.8 to 40.8 percent for T.P. Collectively, these results demonstrated the best suspended solids, chlorophyll and macronutrient removal capacities reported for any mariculture wastewater treatment methodology to date.

Compared with settlement ponds (Fig. 1), which are currently implemented in Australia as an industry best practice, the PASF system offers better water treatment that does not rely on lengthy settlement periods, uses a smaller farm area and produces marine worm biomass that can add to the productivity of the farm. It also compares favorably with a range of other biological and mechanical wastewater treatment approaches that have been tested by the Department of Employment, Economic Development and Innovation over the last 10 years.

Perspectives

The most recent results suggested the PASF method could soon provide a more effective and more productive alternative to settlement ponds in the treatment of pond-based mariculture wastewater. The next step in the development of PASF is to build industrial capacities and support systems to demonstrate its application in treating commercial volumes of wastewater discharge.

(Editor’s Note: This article was originally published in the January/February 2012 print edition of the Global Aquaculture Advocate.)

Author

-

Paul J. Palmer

Agri-Science Queensland

Department of Employment,

Economic Development and Innovation

Bribie Island Research Centre

P. O. Box 2066

Woorim, Queensland 4507 Australia[117,97,46,118,111,103,46,100,108,113,46,105,100,101,101,100,64,114,101,109,108,97,112,46,108,117,97,112]

Tagged With

Related Posts

Aquafeeds

Polychaete worms reduce waste, provide food in aquaculture

Adaptable and diverse, polychaetes can adapt their feeding behaviors to environmental conditions. Nereis diversicolor, a marine polychaete that can tolerate wide temperature and salinity ranges, is a good candidate for RAS enhancement.

Health & Welfare

A study of Zoea-2 Syndrome in hatcheries in India, part 2

Indian shrimp hatcheries have experienced larval mortality in the zoea-2 stage, with molt deterioration and resulting in heavy mortality. Authors considered biotic and abiotic factors. Part 2 describes results of their study.

Innovation & Investment

Aquaculture in Canada: status, perspectives

Canada exports farmed seafood products to more than 22 countries and is the main seafood supplier to the U.S. market. Finfish, primarily salmon, production is strong and shellfish production is growing, but diversification will be imperative to maintain competitiveness.

Health & Welfare

Bacillus probiotics improve hatchery, nursery production in EMS-hit Mexico

In early 2014, a trial to evaluate the effects of a mixture of Bacillus strains on early mortality syndrome bacteria during the larviculture and nursery phases for shrimp was carried out at a commercial hatchery in Mexico.