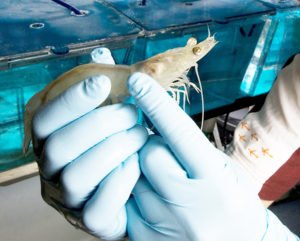

Authors explored both marine shrimp and freshwater prawns

To support the continued growth of shrimp aquaculture in regions that cannot compete with inexpensive imports, a niche market that commands a premium price over imported shrimp must be leveraged. The live market represents a very promising niche for these types of markets.

Since it is difficult and costly for importers to ship live shrimp over great distances, live markets provide an opportunity for underdeveloped shrimp-producing countries to offer local and regional markets live seafood products that can demand a premium price.

Potential niche market

For example, shrimp is the number 1 seafood product consumed in the United States, with an average annual per-capita consumption of 1.8 kg. Over 90 percent of the shrimp consumed in the U.S. is imported, and the majority of imported shrimp is from farmed, not wild-caught sources.

The U.S. has significant interest in further developing its shrimp aquaculture industry. Production of marine shrimp and freshwater prawns in both ponds or recirculating aquaculture systems has been shown to be technically feasible, and commercial enterprises using both systems exist. However, production costs for U.S. growers exceed those of foreign competitors. The U.S. market value of commodity shrimp is depressed due to the high volume of foreign product available.

Since it is challenging for importers to ship live shrimp to the U.S, the live market presents a promising niche for U.S.-grown shrimp.

Shipping live shrimp

Shipping of live shrimp in water can be accomplished when temperature and levels of ammonia, oxygen and carbon dioxide can be controlled. However, the weight of water can be cost prohibitive when product is transported over long distances.

If shrimp can be shipped live without water weight, significant savings would be realized. Accordingly, studies have been conducted to develop handling and packing methods for waterless shipment of live shrimp.

After shrimp are harvested, they must be prepared for shipping. This involves the following steps:

- Anesthetize the shrimp in water by dropping the temperature using ice. Transfer the shrimp and culture water into a smaller tank with aeration. Slowly add ice and monitor the change in temperature. Make sure the dissolved-oxygen concentration remains greater than 5 mg/L.

- Soak packing material in the same water the shrimp are in. Remove the chilled packing material and form a layer on the bottom of a clear fish bag. Lay shrimp in a single layer on the bed of moist packing material.

- Fill a bag with oxygen from a cylinder and tie the bag air tight. For their experiments, the authors used temperature control chambers to maintain the experimental holding temperatures for up to 72 hours.

- Unpack shrimp and see if they have gill movement or respond to prodding to determine if they are still alive. Process the shrimp or put them into tanks of shrimp culturr water on the receiving end.

Research with shrimp, prawns

The authors explored waterless shipping by performed laboratory experiments using both marine shrimp, Litopenaeus vannamei, and freshwater prawns, Machrobrachium rosenbergii. For marine shrimp, the first variable investigated was the anesthetization rate, which included water temperature reduction at 5.0, 7.5 and 10.0 degrees-C/hour. The starting temperature of 30 degrees-C was typical for shrimp culture. The anesthetized temperature was the holding temperature, representative of shipping conditions.

No significant difference in survival for cooling shrimp at rates up to 10 degrees-C/hour was seen. Tests of holding temperatures of 10, 12, 15 and 20 degrees-C for up to 72 hours found the optimum temperature range as 12 to 15 degrees-C.

Various materials were considered to be packed with the shrimp, including wood shavings, sawdust and newspaper. Wood shavings performed significantly better than the newspaper and sawdust. In addition to being “messy,” newspaper and sawdust stuck to the shrimp bodies and obstructed the shrimp from breathing the moist air, and caused more mortalities.

Receiving shrimp was relatively easy. Shrimp that were still alive after the waterless shipping simulation could acclimate to being in tanks as high as 30 degrees-C, regardless of the anesthetized temperature.

Results

The optimum combination for waterless shipping of marine shrimp involved anesthetization with water temperature reduction of 10 degrees C/hour and holding of shrimp out of water at 12 to 15 degrees-C with moist wood shavings for 24 hours. Under these conditions, shrimp survival rates typically exceeded 95 percent. When shrimp were held longer than 24 hours, moderate to poor survival was seen up to 72 hours.

Protocols that were successful for waterless shipping of marine shrimp were also used on freshwater prawns. The optimum conditions for marine shrimp held true for freshwater prawns, with one exception. Freshwater prawns repeatedly did not tolerate temperatures below 14 degrees-C. Although a holding temperature of 15 degrees-C resulted in excellent survival, almost all the prawns died when they experienced temperatures below 14 degrees-C.

(Editor’s Note: This article was originally published in the March/April 2015 print edition of the Global Aquaculture Advocate.)

Authors

-

George J. Flick, Jr., Ph.D.

University Distinguished Professor

Food Science and Technology Department

Center for Applied Health Sciences

Duck Pond Drive

Virginia Tech (0418)

Blacksburg, Virginia 24061 USA -

David D. Kuhn, Ph.D.

Assistant Professor

Food Science and Technology Department

Center for Applied Health Sciences

Duck Pond Drive

Virginia Tech (0418)

Blacksburg, Virginia 24061 USA

Tagged With

Related Posts

Intelligence

We can grow better shrimp, and in better ways

The recent Central American Aquaculture Symposium in Choluteca, Honduras, brought together more than 600 participants to discuss industry issues and perspectives. The focus was shrimp diseases and their impacts on production, as well as practical alternatives to face these issues and move forward.

Intelligence

Critical decisions for shrimp harvesting and packing, Part 1

Harvesting a crop of shrimp is a critical step for any shrimp farming venture. Several months of efforts and resources to properly raise a quality crop have already been invested, and this quality must be preserved. The decision to harvest involves consideration of various factors.

Intelligence

Critical decisions for shrimp harvesting and packing, Part 2

The decision to harvest involves consideration of various factors, including market prices, customers’ need, biomass and condition of the animals and others. Several steps are involved, most aimed at maintaining maximum quality of the animals as they are harvested, sacrificed, treated and transported to the plant and processed and packed.

Intelligence

Critical decisions for shrimp harvesting and packing, Part 3

In this final installment of Hervé Lucien-Brun’s comprehensive three-part series, the author details the final steps in the process of taking farmed shrimp to the marketplace. Here we take a look at the proper protocols for receiving at the processing plant, weighing, grading and freezing.