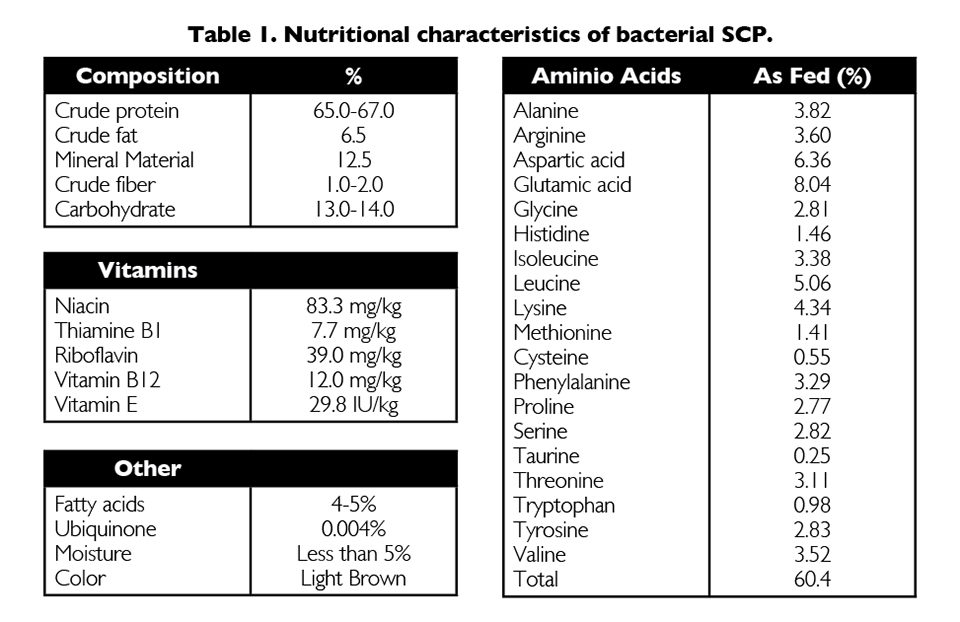

Material contains beneficial nutrients and is free of deleterious levels of mycotoxins and anti-nutritional factors

The aquaculture industry currently supplies approximately 40 percent of the world’s food-fish supplies, and projections indicate this number will continue to increase. Because most production of the aquafeed required to support this industry relies on supply-limited sources of protein such as fishmeal, some individuals and institutions predict future shortages for use in aquafeed.

For example, Norway’s Aquaculture Protein Center website states: “The trends within the industry indicate an insufficient supply of protein sources in the future. Fish protein as an ingredient in fish feed is now more or less fully exploited. Alternative sources must be found. Such alternatives can be plant-derived protein, protein from microorganisms, or from other marine organisms further down the food chain.”

Oberon FMR, Inc., a Denver, Colorado, USA-based biotechnology firm, has developed technology to convert wastes produced during food processing into a valuable single-cell protein (SCP) ingredient for aquafeed. This process, which evolved over the last decade, is applicable to a wide variety of plant-based carbohydrate residuals and has cost advantages over other premium proteins.

Ingredient alternative

Over the past 40 years, much research has been performed in the area of protein and food alternatives. These studies have included yeast, algal and bacterial SCPs derived from plant and animal wastes, as well as petrochemicals and hydrocarbons. Many of these efforts showed that SCPs have many desirable characteristics as a feed ingredient. More recently, products including distillers grains and other fermented products have come to market on a large scale.

The benefits of microbes in the form of biofloc – a mixture of algae, bacteria and multicellular organisms – within shrimp and tilapia culture systems are well known. Bacteria and fermented products are clearly part of aquaculture’s future.

The waste-based bacterial SCP product is a nutritious and desirable ingredient for use in feeds (Table 1). The material contains beneficial quantities of vitamins and minerals, coenzymes and free nucleic acids (8 to 12 percent of sample), and is free of deleterious levels of mycotoxins, anti-nutritional factors and other constituents that limit its use in aquafeeds.

SCP production

Production of SCPs through the utilization of food-processing wastes offers varied benefits. The utilization of a waste as the growth medium significantly improves the economics. Bacteria can thrive in a variety of environments and utilize a variety of growth substrates, which leads to a scalable process.

The protein content and amino acid composition of bacterial cells is very similar to those of fishmeal. Bacterial generation times are much shorter than those of yeasts or algae, often on the order of 20 to 30 minutes rather than the hours or even days required by the other organisms.

The authors estimate that the global production potential of food-processing SCPs is in excess of 1 mmt annually. Large-scale production of this bacterial SCP for use in aquaculture could result in environmental benefits to marine and coastal ecosystems, as the need for wild fish as an aquafeed ingredient is reduced. In addition, wastewater treatment center operations will see economic benefits by realizing a valuable product from wastes that currently require disposal. Improved economics of wastewater treatment will also provide a stimulus for increased treatment of wastes in the developing world, where much wastewater is discharged without treatment.

Feeding trials

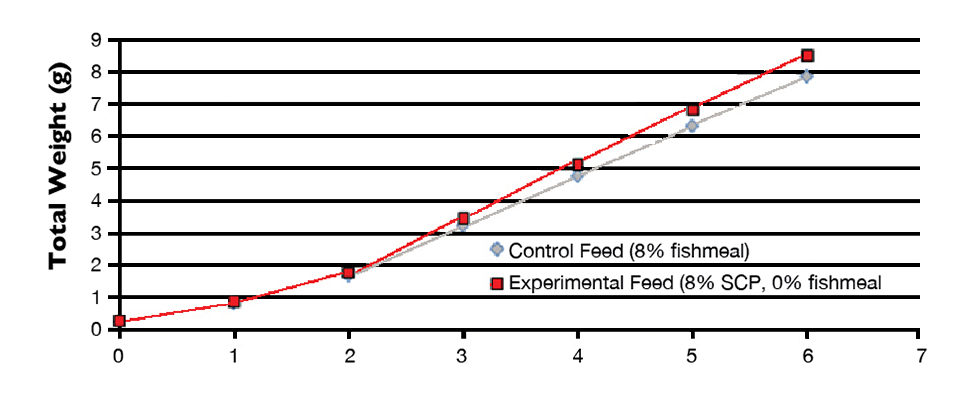

The authors performed feeding trials with Pacific white shrimp (Litopenaeus vannamei) and recorded excellent growth and health in animals that consumed SCPs in their diet (Fig. 1). During a trial at Texas Agrilife Mariculture Lab in Port Aransas, Texas, USA, white shrimp performed as well or better on feeds formulated with SCP and no fishmeal as they did on fishmeal-based feeds. This work is ongoing.

Past and ongoing feeding trials with salmon, rainbow trout, tilapia, yellowtail, poultry and pigs have also shown promising results.

Recent activities included a full-scale demonstration at a major brewer in the United States. Full-scale implementation of the SCP process – planned for September 2011 – would result in the daily production of 15 tons of SCP. To meet the anticipated needs of the industry, additional production facilities could be started every 10 months thereafter.

(Editor’s Note: This article was originally published in the November/December 2010 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Andrew J. Logan, Ph.D.

Vice President, Research and Development

Oberon FMR, Inc.

831 Pearl Street

Boulder, Colorado 80302 USA -

Addison Lawrence, Ph.D.

Texas A & M University – Corpus Christi

Corpus Christi, Texas, USA -

Warren Dominy, Ph.D.

Aquatic Feeds and Nutrition Department

Oceanic Institute

Waimanalo, Hawaii, USA -

Albert G.J. Tacon, Ph.D.

Aquatic Farms Ltd.

Kaneohe, Hawaii, USA

Tagged With

Related Posts

Aquafeeds

A look at phospholipids in aquafeeds

Phospholipids are the major constituents of cell membranes and are vital to the normal function of every cell and organ. The inclusion of phospholipids in aquafeeds ensures increased growth, better survival and stress resistance, and prevention of skeletal deformities of larval and juvenile stages of fish and shellfish species.

Aquafeeds

Animal co-product hydrolysates sources of key molecules in aquafeeds

Key molecules found in animal byproduct hydrolysates show potential for use as functional ingredients in aquaculture feeds. Animal co-product hydrolysates from slaughterhouse waste and rendered animal byproducts present a protein alternative.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.