Genetic, phenotypic trends after generation of selection

Genearch Aquacultura, a Brazilian shrimp-breeding company associated with Aquatec, the leading commercial hatchery in the country, initiated the specific pathogen-free (SPF) era in Brazil with SPF Litopenaeus vannamei imports in 2006. After a series of comprehensive commercial field tests in ponds under local conditions, the genetic format to be adopted by the incipient breeding program was defined, and a program was initiated.

Genetic improvement

From the series of four preliminary field tests, it was concluded that the best course for the Genearch SPF genetic improvement program would be the constitution of a synthetic/composite SPF population bringing together contributions from all six SPF founder populations. The founders have been separately perpetuated and maintained alongside the main breeding and selection program for purposes of genetic variability preservation.

One genetic batch of 60 full-sib families is produced every three months with a total of 240 full-sib families produced every year. Some 500 to 600 tagged animals are stocked per family in the genetic nucleus (G.N.) performance tests, and 150 animals/family are stocked in a pond field test conducted with every batch. The field tests are managed under commercial conditions that reflect the prevailing shrimp production realities in Brazil.

The selection program includes family selection based on a selection index combining G.N. and field test genetic merit estimates for growth and survival. Within-family selection for growth in the G.N. tests in the breeding center – in a biofloc system at stocking densities of 100 to 150 shrimp per square meter – are also considered.

Family identification is through elastomer tagging when animals reach the 2-gram juvenile stage. Best linear unbiased prediction (BLUP) methods are used to statistically examine random effects in linear mixed models.

Results

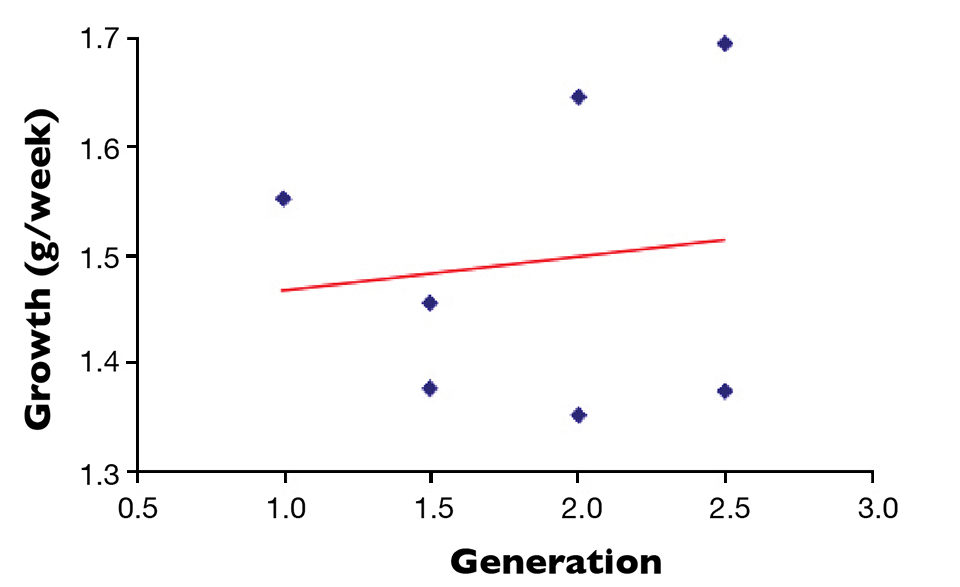

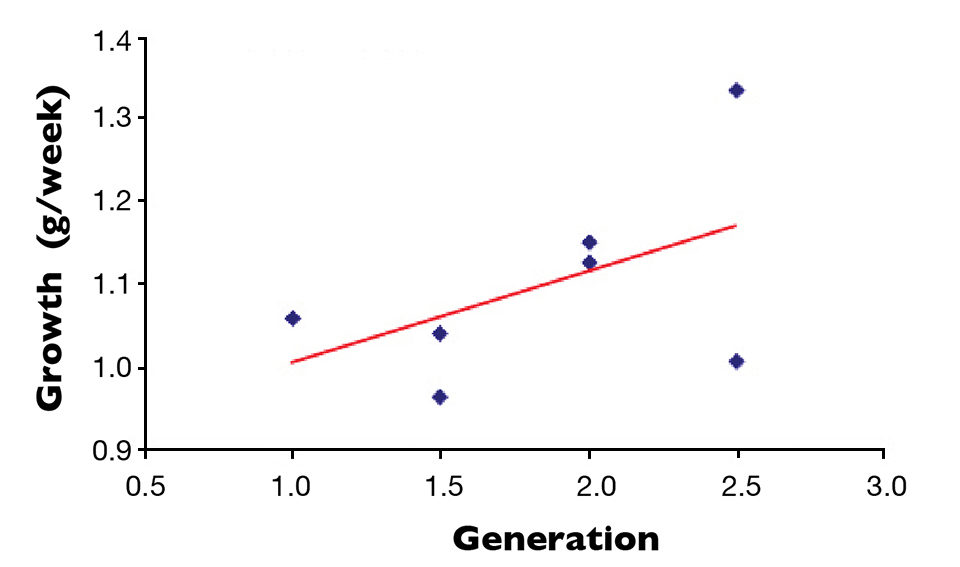

The first genetic batch was produced in 2007. The first three batches were first-generation batches derived from crosses among the different SPF founder populations. Batches 2 and 3 were considered to belong to generation 1.5 in Figs. 3 to 6, and batches 4 through 7 were second-generation, already reflecting one generation of family and within-family selection for growth and survival. Batches 6 and 7 belong to generation 2.5 in Figs. 3 to 6. The performance tests for batch 7 were recently evaluated.

After one generation and four batches of index selection combining G.N. and field test genetic merit estimates for growth and survival, it became clear that moderately strong genetic/environment interactions between the G.N. and field test environments played an important and unfortunate role, as well as mildly antagonistic correlations between growth and survival in the field test environment.

Both realities negatively impacted expected genetic improvement rates, especially for the field test environment. The establishment of two separate breeding lines was therefore recommended.

One line targeted the current commercial environment in Brazil: low stocking densities under 40 shrimp per square meter and reduced levels of management in usually large ponds. The other line targeted more intensive systems stocked at densities of 100-200 shrimp/m2 under higher levels of management. The latter systems are scarce in Brazil, but could become more important in the future.

Trends

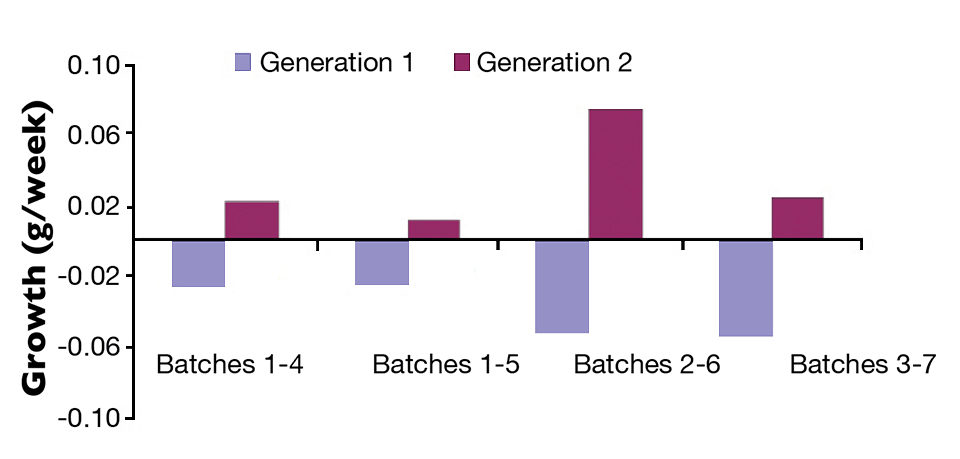

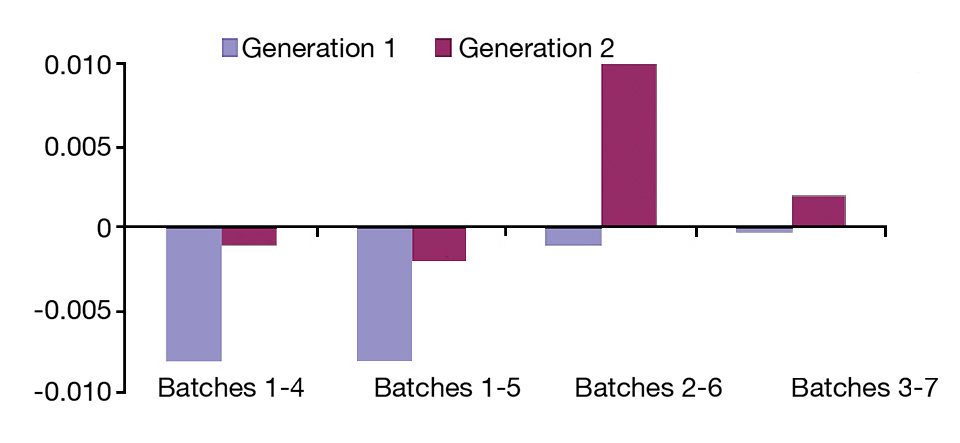

Genetic and phenotypic trends registered for the G.N. environment traits in the SPF breeding program after four batches and one generation of selection are shown in Figs. 1 to 6. Due to the previously mentioned genetic and environmental (G x E) interactions between the G.N. and field test environments, the BLUP estimates for the first-generation average genetic gain rates obtained for the G.N. growth traits were lower than expected (Fig. 1 – 5.3 and 6.6 percent of the mean harvest weight and weekly growth, respectively). However, the situation will be corrected with the establishment of two separate lines, each targeting one of the two different environments.

This conclusion was validated by the reasonable genetic gain rates obtained in the second-generation batch 6, derived from the family selections implemented in batch 2 (Figs. 1 and 2). By chance, it was not possible to conduct a field test for batch 2, so its family selections were not impacted by G x E interactions. Batch 2 family selections reflected the G.N. performance test results.

The genetic gains obtained for the G.N. growth traits in batch 6 were fairly good (8.6 and 10.4 percent of the mean harvest weight and weekly growth, respectively), and very close to the theoretical expectations for a program with the characteristics and scale of Genearch’s breeding program. The G x E interactions were mainly responsible for the low average genetic gain rates obtained for the G.N. growth traits during the first generation of selection.

Perspectives

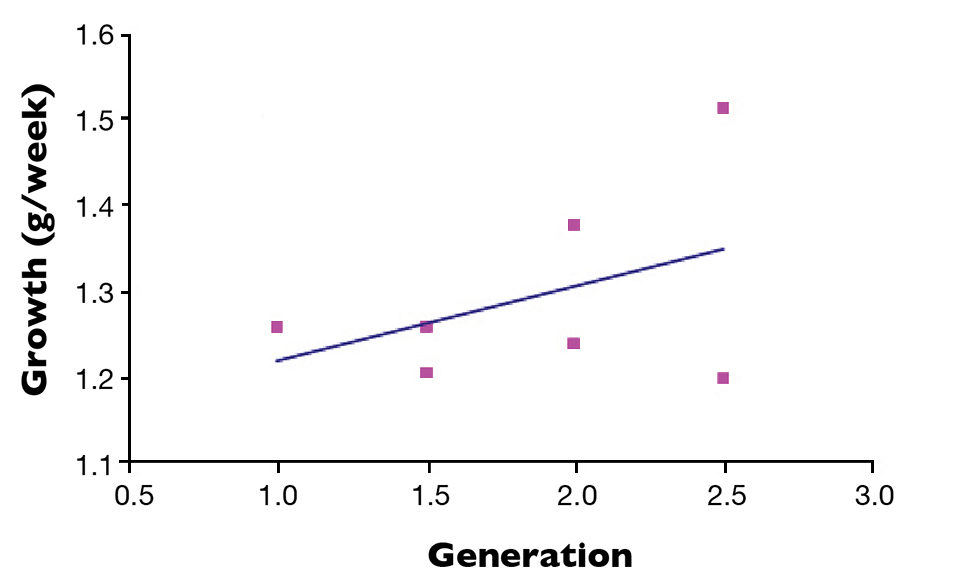

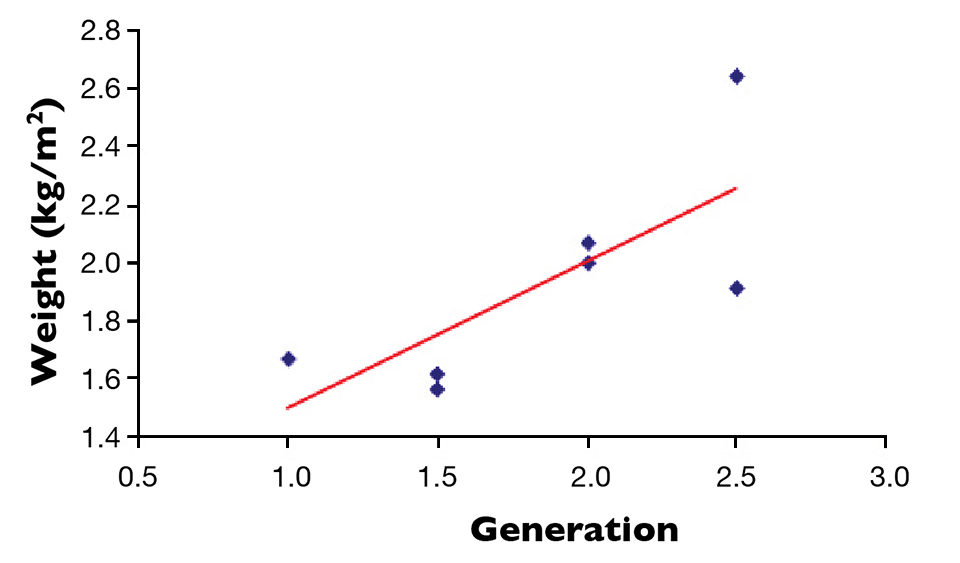

The phenotypic trends observed in the SPF breeding program for the G.N. testing environment traits were very encouraging, reflecting the genetic improvement made (Figs. 1 and 2), but also other factors. Batch 7, whose performance tests were recently evaluated, registered all-time records in the G.N. testing environment with an average weekly growth rate of 1.513 grams and a total harvested biomass of 2.64 kg per square meter for a stocking density of 167.5 shrimp per square meter.

These results bear witness to the potential of selected animals to excel under well-managed intensive production systems stocked at high densities. It is expected that the genetic improvement program, now unhindered by G x E interactions, will further accentuate the potential for establishing a line suitable for the actual commercial conditions prevailing in Brazil.

(Editor’s Note: This article was originally published in the May/June 2010 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

João L. Rocha, Ph.D.

Genearch Aquacultura Lda.

Praia de Pititinga

RN, CEP 59578 Brazil -

Ana C. Guerrelhas

Genearch Aquacultura Lda.

Praia de Pititinga

RN, CEP 59578 Brazil -

Ana K. Teixeira

Genearch Aquacultura Lda.

Praia de Pititinga

RN, CEP 59578 Brazil -

Flávio A. Farias

Genearch Aquacultura Lda.

Praia de Pititinga

RN, CEP 59578 Brazil -

Ana P. Teixeira

Genearch Aquacultura Lda.

Praia de Pititinga

RN, CEP 59578 Brazil

Tagged With

Related Posts

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Health & Welfare

A study of Zoea-2 Syndrome in hatcheries in India, part 1

Indian shrimp hatcheries have experienced larval mortality in the zoea-2 stage, with molt deterioration and resulting in heavy mortality. Authors investigated the problem holistically.

Health & Welfare

A study of Zoea-2 Syndrome in hatcheries in India, part 2

Indian shrimp hatcheries have experienced larval mortality in the zoea-2 stage, with molt deterioration and resulting in heavy mortality. Authors considered biotic and abiotic factors. Part 2 describes results of their study.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.