System developed in Denmark and introduced to Taiwan in 1993

Water of appropriate quality and adequate quantity is essential for the success of any aquaculture venture. In countries where aquaculture has expanded rapidly, the demand for water has also drastically increased. In Taiwan, the excessive use of water for aquaculture has resulted in land subsidence and intrusion of seawater into the water table. Prudent use of water in aquaculture, therefore, has now been recognized as critical in making the industry sustainable and preventing environmental impacts.

The intensification of aquaculture production by employing recirculating culture systems is considered as one way to increase production output while at the same time minimizing resource use, particularly water, and preventing negative effects on the environment. In Taiwan, the development of super-intensive recirculating culture systems has been actively carried out for the last seven years, not only in response to environmental concerns but also to prevent serious disease problems. At the present, such systems are being used on commercial scale for the super-intensive culture of eel. Another recirculating culture system is being tested in the laboratory for rearing grouper larvae and juveniles.

Recirculating eel culture

Taiwan is the second biggest producer of cultured eel in the world. Production of cultured eel peaked in 1992 at about 58,966 metric tons, valued at $600 million. Cultured eel from Taiwan comprised about 50 percent of the total imports of the Japanese market between the late 1980s and the early 1990s. During this period, Taiwanese farmers used conventional pond culture systems, which had a great impact on groundwater supply. As much as ten tons of water was needed to produce a kilogram of eel.

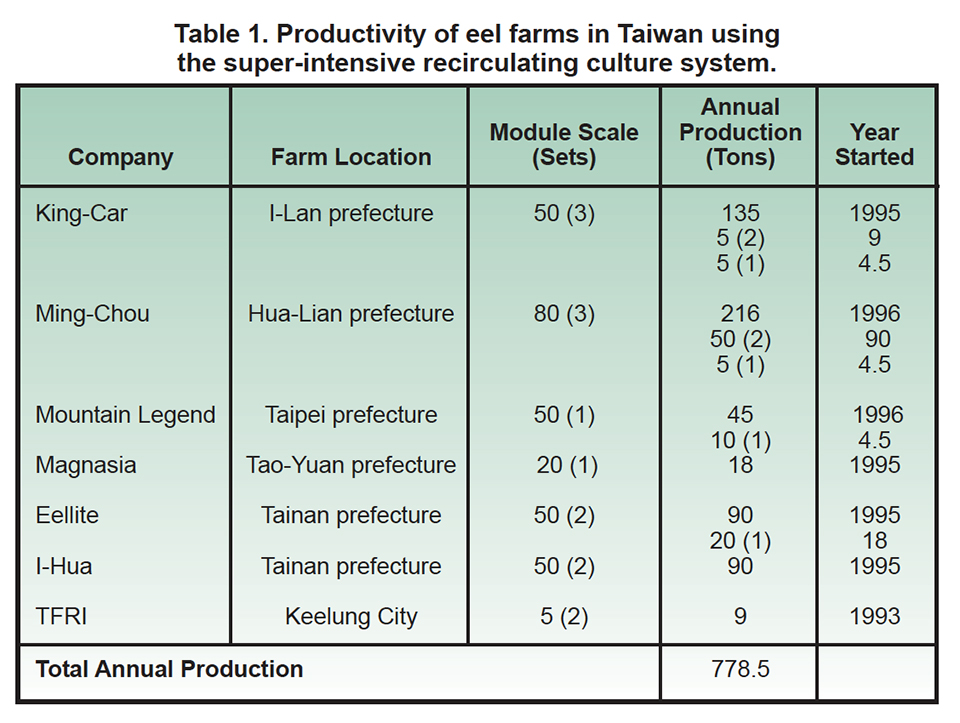

The super-intensive recirculating culture system, developed in Denmark, was introduced to Taiwan in 1993 as a low-water-usage alternative for eel farmers. Since then, the system has been tested in the culture of European eel (Anguilla anguilla) and Japanese eel (A. japonica), as shown in Figs. 1 and 2. At present, six commercial eel farms have adopted the system (Table 1). Stocking densities as high as 80 kilograms per square meter are possible using this system, in contrast with 2 to 3 kilograms per square meter in the traditional concrete or earthen pond culture system. Furthermore, the volume of water used to produce one kg of eel is less than 5 percent of that used in the traditional system. And with the recirculating culture system, the survival rate may reach 90 percent if good management is provided.

The high initial investment cost is one of the disadvantages of the superintensive system. To assist the aquafarmers in establishing their facilities, the government provides partial subsidies or low interest loans. The relatively slow growth of eel in the later phase of the culture is another drawback of the current system. To solve this problem, a two-phase rearing process, in which the eels are reared to about 100 grams in size in the super-intensive recirculating culture system during the first phase and then transferred to outdoor ponds until they reach marketable size, has been developed.

Several software programs with suitable hardware are available to automate and monitor the system. A production management software program has been designed to assist farmers in managing the eels in the tanks. The program can handle ten sets of super-intensive, recirculating eel culture systems, and each set can be used to monitor a maximum of 100 tanks. The program provides sufficient space for eel farmers to expand their systems and culture more than one eel species at a time.

Prospects

Continuous innovation of aquaculture production systems is necessary to make the aquaculture industry sustainable, environment-friendly and economically viable. Super-intensive recirculating culture systems are a promising alternative to the traditional culture systems that use up a significant quantity of water and release effluents back to the natural environment. In Taiwan, the present super-intensive, recirculating culture systems have so far allowed culture at high densities and kept the use of water at a minimum, thereby markedly reducing the discharge of effluents, preventing viral infections, and enhancing survival. However, the systems still require substantial capital investment. Current R&D is directed towards production optimization, to make the operating cost of the systems more competitive compared with the traditional production systems.

The wider use of recirculation culture systems for other species deserves further study. Tests at the Tungkang Marine Laboratory, Taiwan Fisheries Research Institute, of a super-intensive recirculating culture system for grouper larvae and juveniles have shown promising results. Grouper larvae are extremely susceptible to deteriorating water quality. Viral diseases are also commonly observed, coincident with poor water quality. An indoor recirculating culture system for grouper larval rearing has been recently established to enhance the growth and survival of grouper larvae and juveniles, particularly during the weaning stage. Using this system, grouper juveniles grow from 3 to 10 cm with almost no mortality and viral infection and with daily weight increase from 4 to 27 percent.

As aquaculture production continues to be intensified in the future, the use of super-intensive recirculating culture systems will further expand. The need for a safe closed system, in rearing transgenic fish for instance, will push the wider utilization of recirculating culture systems. In Taiwan, where biotechnology is currently a major aquaculture R&D area, such a trend is very much anticipated in the near future.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

I Chiu Liao, Ph.D.

Taiwan Fisheries Research Institute

199 Hou-Ih Road

Keelung 202, Taiwan[119,116,46,118,111,103,46,110,105,114,102,116,46,108,105,97,109,64,111,97,105,108,99,105]

Tagged With

Related Posts

Innovation & Investment

American Unagi brings eel farming back ‘home’

Sara Rademaker launched American Unagi to shift eel farming to American soil, where the eels are from. Why? Because of the novelty, and because she saw an opportunity to do things better.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Health & Welfare

Eel production in Europe

After rapid expansion of glass eel culture in the mid-1990s was followed by overproduction, pricing problems, glass eel shortages and NGO pressures, European Union countries adopted national management plans for the eels. Importation of consumption eels was stopped, and exportation was phased out.

Health & Welfare

Japanese eel aquaculture in Korea

After a decade of research, Korea has produced individual glass eels for Japanese eel aquaculture. Despite dependence upon the wild seed, Japanese eel aquaculture production has been growing significantly and comprises over 27 percent of Korea’s freshwater aquaculture.