Can this publicly traded biotechnology company help break the bottleneck for aquafeed producers?

You could say that an innovation is a problem solved. For aquaculture, a reliance on wild fisheries to provide key ingredients for feeds was long viewed as the main bottleneck to expansion.

As fish farmers have become the world’s largest consumers of fishmeal and fish oil, aquafeed producers, by necessity, have branched out into novel proteins, alternative land-based ingredients like soy, biotechnology and new, research-intensive feed formulations designed to stretch natural resources.

And like so many innovative solutions achieved in the world of digital technology, a potential fix to aquaculture’s existential issue was born in Silicon Valley. In a garage, no less.

In 2003, two friends from Emory University – Jonathan Wolfson and Harrison Dillon – started working with microalgae in Wolfson’s Palo Alto, Calif., garage with the goal of creating an algae-based, renewable fuel source.

Much like the founders of Hewlett Packard, Apple or other masters of the microchip who devised life-changing inventions in low-budget locales, Wolfson and Dillon wanted to create something that had never existed before. They sought to create a product that would change the way people thought about plants and renewable energy. And they’d do it by fermenting microalgae – taking a plentiful, inexpensive and sustainable resource that grows quickly, and in almost any environment, and converting it into a more valuable, higher-level ingredient.

“Originally when the company was founded it was focused on using microalgae to turn sugar into oil, with a heavy emphasis on biofuels at the time,” explained Walt Rakitsky, Ph.D, senior vice president of emerging business at TerraVia.

What started as a dream at the end of a driveway is now a publicly traded biotechnology company (NASDAQ:TVIA) with headquarters in South San Francisco. There are challenges – the company reported a net loss of $26.5 million in the first quarter, it operated at a net loss of $101 million in 2016, and is carrying a heavy debt load – but none of this is uncommon for a Silicon Valley company with lofty goals.

What’s more, management remains dedicated to its technology and resolved by what it sees as robust demand for healthier and more sustainable products in food, aquaculture, animal nutrition and specialty personal care products, and is ramping up production. Should these expectations play out, TerraVia and its investors could be at the forefront of the next big thing in nutrition.

“And I think what the company has successfully done over the years is develop an incredibly valuable technology platform that uses both native microalgae to create ingredients, as well as oil and fats,” Rakitsky said. “And we can also modify the microalgae, so that instead of making oil that it naturally makes, it can make something like a cocoa butter, or something like a palm kernel oil.”

Algae already in your food

This is not algae as most people know it. The technology that TerraVia utilizes involves microalgae that convert sugars into oils and other ingredients. As a large-scale industrial process, this technology allows feed producers to predict and forecast availability, pricing, supply and other variables, with final products that don’t get contaminated like a natural algae in the outdoors would.

TerraVia recently began using this technology to invest in human and animal nutrition, launching AlgaVia protein powders and lipid powders, as well as AlgaWise oils and fats that are used by food producers. These ingredients are currently used by mainstream food producers including Utz, Hormel, Mondelez and more. And its Thrive® Algae Oil is growing in popularity with home cooks across the country.

This is an excellent way for us to provide even more health and bring us that omega-3 without putting pressure on resources. And this for sure takes away a little bit of the uncertainty of our ability in general to grow the industry, due to the limited amount of fish oil out there globally.

Last year, the company launched AlgaPrime DHA, which the company calls a “traceable, sustainable, high-quality alternative to fish oil.” According to Rakitsky, this new, algae-based source of omega-3s will allow the aquaculture and livestock industries to expand in an environmentally friendly way, while simultaneously helping get more healthy, omega-3 fatty acids into human and animal diets.

“Until now, people have been talking about new sources of omega-3, but nobody’s actually had the scale and the ability to make it at scale that’s relevant,” Rakitsky said. “It’s always been, ‘It’s coming, it’s coming.’ So we jumped on the scene, and said, ‘We’ve got an asset. We’re ready to go.’ There’s a well-known deficiency of long-chain omega-3s. We only have so much in the ocean, and both humans and animals need a lot more than we have. It’s always going to be this fight for a scarce resource.”

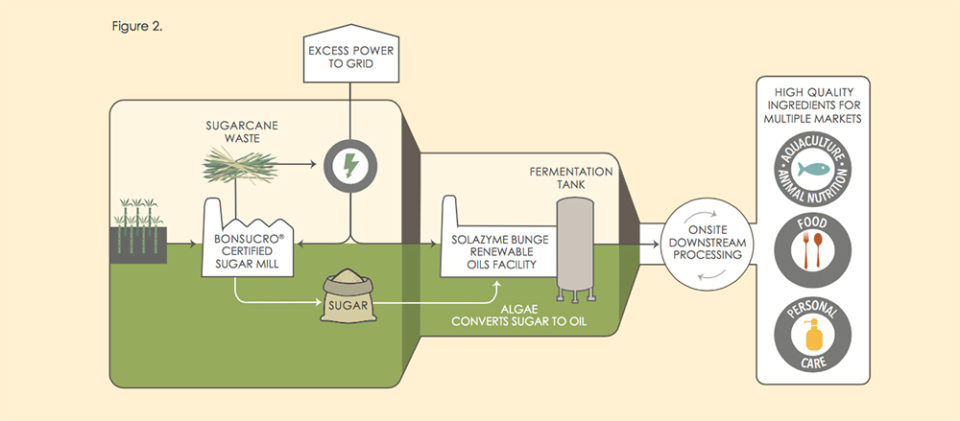

TerraVia’s secret sauce in aquaculture, he said, is that it is an established microalgae company with large-scale access to production facilities and a technology platform that’s robust and scalable in order to meet the needs of aquafeed producers. It boasts some sustainability bona fides, as it employs a non-GMO seed stock, uses little water and relies on excess energy – the company’s plant in Brazil is co-located at a sugarcane mill and runs off of the steam that the sugar cane processing creates.

A budding partnership with BioMar

With its first step into aquafeed, TerraVia partnered with Denmark-based feed producer BioMar. The agreement has allowed BioMar, a major supplier to the salmon industry, to begin to address the omega-3 shortage that has plagued the sector.

“This is an excellent way for us to provide even more health and bring us that omega-3 without putting pressure on resources,” said Jan Sverre Røsstad, BioMar’s vice president. “And this for sure takes away a little bit of the uncertainty of our ability in general to grow the industry, due to the limited amount of fish oil out there globally.”

The market reaction has so far been positive, he said, with several high-profile aquaculture firms using products from the collaboration. In recent months, Leroy, the largest salmon producer in Norway, and Ventisqueros, a salmon farmer in Chile, both announced plans to use AlgaePrime-supported feeds.

Fermented microalgae isn’t necessarily changing the nature of aquafeeds, Røsstad said, but the combination of these advanced new ingredients and established products is what feed producers and farmers each need.

“What we are really working with is an additional element in many ways to what has been a tradition within the feed industry,” he said. “We have been working for many, many years with feed performance, getting the efficiency into the feed, the cost potential into the feed. But this message that we’re able to provide here is a little bit of an additional thing and it’s very, very satisfactory that we can offer this now.”

For TerraVia, this is just the first step in what the company hopes is a long and productive partnership. The technology is up and running, the market need is there, and the potential applications for microalgae – in aquaculture and beyond – is significant.

“There’s a huge, huge need out there for new sources of marine omega-3s,” said Rakitsky. “There’s just not enough in our ocean in any way, shape or form to meet the needs on the human side and the animal side. We’re here now, today, and we’re ready to go and help address this shortfall.”

Author

-

Tim Sprinkle

Tim Sprinkle is a writer based in Denver, Colo. His work has appeared in Wired, Outside and many other publications, and he is the author of the 2015 book, “Screw the Valley: A Coast-to-Coast Tour of America’s New Tech Startup Culture.”

Tagged With

Related Posts

Innovation & Investment

Competitiveness comes at scale for RAS operations

Total RAS salmon production worldwide is less than half of 1 percent of total production. Many of the investors flocking to the sector now are new to fish farming, and confident in its potential.

Aquafeeds

Bridging the omega-3 gap with methane, microalgae

Innovation is leading to new ingredient options for renewable sources of omega-3 fatty acids. But Replicating long chain fatty acids is a tall order, Advocate contributor Lisa Duchene discovered.

Aquafeeds

Talent show: Aquafeed companies show off at F3

Aquafeed manufacturers and alternative feed ingredient suppliers from all over the world gathered in Silicon Valley for F3, the Fish Free Feed contest. In the hub of innovation, solutions to a global problem were on full display.

Aquafeeds

Why I chose to judge the F3 challenge

In an opinion piece for the Advocate, the director of ocean sustainability science at the New England Aquarium talks about the F3 Challenge and what the first X Prize for aquaculture could do for the industry: drive innovation.