Research extends to southern flounder, summer flounder, hybrid striped bass and black sea bass

A collaborative effort between the Agricultural Research Service (ARS) of the United States Department of Agriculture and Harbor Branch Oceanographic Institute at Florida Atlantic University established to develop technologies for rearing marine fish in low-cost, energy-efficient, low-salinity recirculating aquaculture systems is making strides.

The program brings together a diverse group of researchers and utilizes a holistic, integrated approach to address bottlenecks in reproduction, larval culture, nutrition, recirculating system design and components, and management and production strategies for growing marine fish to market size. Work has been conducted with species as diverse as southern flounder, summer flounder, hybrid striped bass and black sea bass. More recently, research is focusing on developing technologies to rear Florida pompano and cobia from egg to market.

Reproduction and larviculture

The development of methods to ensure sustainable, consistent supplies of seedstock for growout operations remains a priority. To date, captive broodstock populations of pompano and black sea bass have been established from wild-caught fish as well as mature F1 animals produced at the ARS facility at Harbor Branch Oceanic Institute.

Protocols have been developed for predictable volitional spawning throughout the year via the use of hormonal inducement for both species. In addition, fecundity, fertilization rates and hatching success have been documented during numerous spawning trials conducted over the last four years. Ongoing research is designed to determine optimal broodstock sex ratios for pompano, as well as photothermal regimes and environmental cues to achieve natural spawning on a year-round basis.

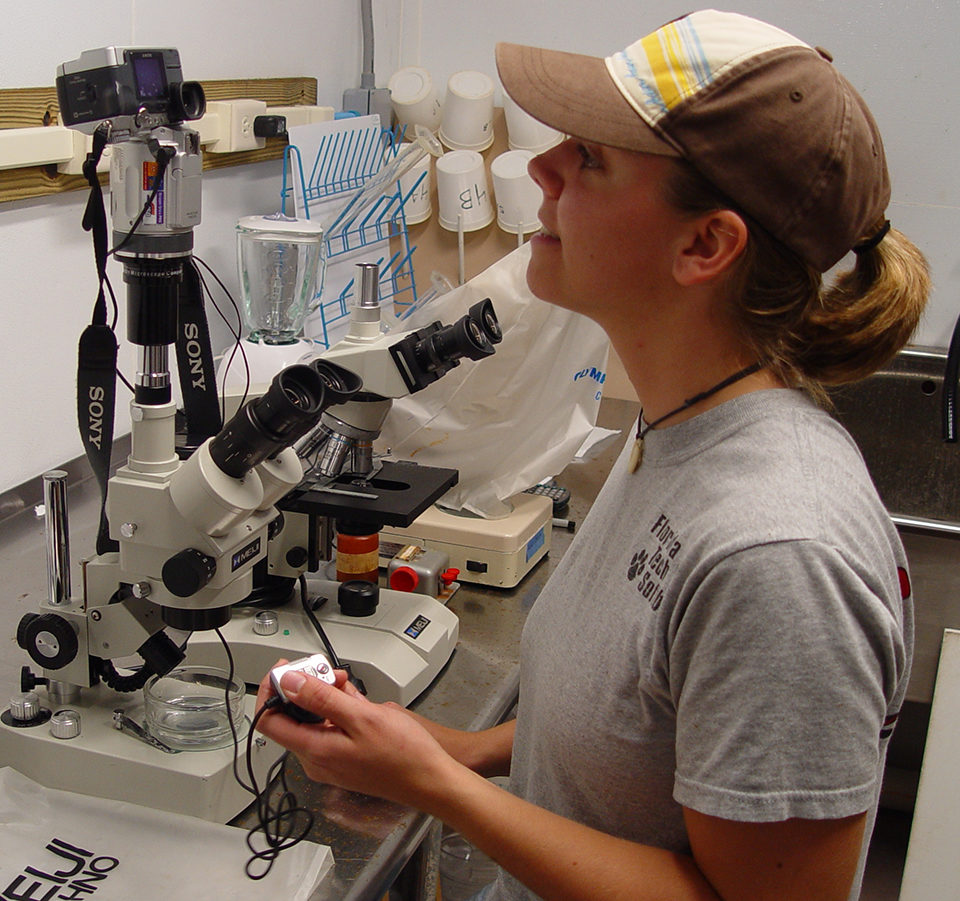

The larval production research has led to the establishment of baseline protocols for the mass production of juvenile pompano in recirculating systems while refining methods that result in improved growth and survival, and reduced time to metamorphosis. For example, growth and developmental characteristics, including predicted mouth gape at a given age in larval pompano and black sea bass, have been documented through the use of image analysis. With this information, optimal prey size can be determined, allowing the development of improved feed transition schedules, faster growth and better survival.

Improved live feed quality for pompano larvae is also being addressed. Evaluation of various commercial enrichment formulations for rotifers and artemia suggested the enrichment of rotifers can be cut from 12 hours to three hours – greatly reducing time and cost. Initial cofeeding experiments to reduce the use of artemia by weaning pompano onto microparticulate diets as soon as possible indicated weaning can coincide with metamorphosis at 16 to 18 days after hatching. The authors are also evaluating compounds for use as feeding attractants to increase the growth and survival of early postmetamorphic pompano.

Nutrition and physiology

Optimum growth and efficiency in fish depend on feeds that are balanced to meet nutrient and energy requirements. The authors determined that optimal growth in black sea bass was achieved at 45 percent dietary protein. Dietary energy was increased by increasing dietary lipid levels, with 10 percent dietary lipid resulting in the best performance and higher lipid levels.

Pompano grew best when dietary protein was 48 percent (37 percent digestible protein). However, to attain the greatest growth and efficiency, pompano required 18 percent dietary lipid – more than for black sea bass. Additionally, the diets developed for black sea bass performed well when the fish were reared in decreasing salinity down to 10 ppt. Conversely, pompano did not perform as well when reared at a salinity below 1 ppt, suggesting the diets did not meet their requirements at that salinity. Work is ongoing to address this issue, as well as the determination of essential amino acid requirements for pompano.

As with other carnivorous species, black sea bass and pompano grow and perform well when the principal component of dietary protein is fishmeal. However, fishmeal is expensive, and supplies are anticipated to dwindle. Therefore to achieve economic and ecological sustainability, the authors are evaluating alternatives to fishmeal protein.

They have determined protein and energy digestibility, and amino acid availability from soy products, corn gluten meal, meat-and-bone meal, distillers’ dried grains and various poultry by-product meals and blended meals in pompano cultured at high and low salinities. Nutrient availability was generally high for the plant proteins and poultry processing products.

Growth experiments were conducted to determine the amount of soybean meal and soy protein isolate that could replace fishmeal in pompano diets. Results suggested soybean meal could replace up to 80 percent of fishmeal, whereas more than 40 percent replacement with soy protein isolate significantly decreased growth and efficiency. Additionally, an evaluation of five poultry processing coproducts substituted for 75 percent of the fishmeal protein in a fishmeal/soybean meal diet found the pompano grew as well over 10 weeks as the fish fed the control diet.

Engineering advances

A key area of interest is to decrease the amount of energy – and accompanying cost – required for moving water in recirculating systems. The most common method for moving water in a recirculating aquaculture system is use of a centrifugal pump. However, airlift pumps offer a simpler alternative with lower capital and operational costs that uses the buoyancy of the entrained air bubbles to lift the water.

The authors evaluated the use of airlift pumps in a 7.9-cubic-meter circular fiberglass tank with 1-meter water depth. Water moved by gravity down a polyvinyl chloride approach pipe to a 10-cm-diameter airlift riser pipe and was airlifted back into the tank using air supplied by a regenerative blower.

The static water lift back into the tank was no more than 30.5 cm to maintain a submergence:lift ratio greater than 80 percent. Additionally, the water velocity in the approach pipe was at least 61.0 cm/second, and the water flow velocity in the riser pipe was at least 30.5 cm/second.

Results indicated the dynamic head increased with increasing water flow. A greater freeboard in the tank increased the airlift needs, and consequently, a greater air flow was required to maintain a set flow rate in the tank. Also, by placing the air injection lower in the riser pipe, a greater flow per unit of air was realized.

As a result of this information, the authors are utilizing airlifts for a juvenile production system with a 30 percent reduction in energy use. They also evaluated airlift technology for supplying aeration for fish and filter needs, as well as degassing in a recirculating system. Other system components for total ammonia nitrogen and solids removal, and water, energy and supplemental oxygen use have also been evaluated in a low-head system.

Production of market-size fish

To collect production data on market-size fish, the authors utilized four replicate four-tank systems. The 3-meter-diameter tanks incorporated dual drains with solids removal carried out using swirl separators and a rotating microscreen drum filter on each system. Each system had two floating media biofilters with a controller for automatic backwashing. An oxygen contactor and ultraviolet light sterilizer treated the water prior to its return to the culture tanks. A side stream also fed to two degassing columns for carbon dioxide removal.

Completed studies evaluated the growout of hybrid striped bass, pompano and cobia to marketable sizes in the recirculating systems. In a 110-day rearing trial, juvenile pompano with initial weights of about 259 grams were stocked at two different densities and maintained at a salinity of 5 ppt. At the conclusion of the trial, the mean weights of fish reared at low and high densities – 632 and 570 grams, respectively – equaled or exceeded those of wild-caught pompano marketed commercially. Although feed-conversion rates (FCRs) were relatively poor, the results showed that pompano can be reared to market size in recirculating systems with a low-salinity environment.

In a similar study, juvenile cobia with 322-gram initial weights were reared at three different densities for 119 days in a recirculating system. At the conclusion of the trial, the mean weight of fish reared at each density was 2.1 kg, with excellent FCR, survival and 42 percent fillet yield. Results from the initial pompano- and cobia-rearing trials showed promise in that both species were grown to market size in a relatively short period of time.

To expand on these results, studies are planned to evaluate factors such as increased culture density, feed rate and frequency, as well as finishing diets to improve FCR. In addition, research on technologies for the remediation of system-induced off-flavors and economic analyses of production costs are ongoing.

(Editor’s Note: This article was originally published in the January/February 2009 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Marty Riche, Ph.D.

Sustainable Marine Aquaculture Systems

USDA Agricultural Research Service

5600 U.S. 1 North

Fort Pierce, Florida 34946 USA -

Charles R. Weirich, Ph.D.

Sustainable Marine Aquaculture Systems

USDA Agricultural Research Service

5600 U.S. 1 North

Fort Pierce, Florida 34946 USA -

Timothy J. Pfeiffer, Ph.D.

Sustainable Marine Aquaculture Systems

USDA Agricultural Research Service

5600 U.S. 1 North

Fort Pierce, Florida 34946 USA -

Paul S. Wills, Ph.D.

Center for Aquaculture and Stock Enhancement

Harbor Branch Oceanographic Institute

at Florida Atlantic University

Fort Pierce, Florida, USA -

Megan Davis, Ph.D.

Center for Aquaculture and Stock Enhancement

Harbor Branch Oceanographic Institute

at Florida Atlantic University

Fort Pierce, Florida, USA

Tagged With

Related Posts

Aquafeeds

Evaluating dietary fish oil replacement in juvenile Florida pompano

Study evaluated production performance and tissue composition of juvenile Florida pompano fed diets containing fish oil or 25:75 blends of fish oil and various other lipid sources.

Health & Welfare

High-soy, fishmeal-free diets support Florida pompano growth

The authors have achieved good growth using a fishmeal-free diet for the carnivorous marine fish Florida pompano. In studies, they used pompano as a model marine species in a cost/benefit analysis of two extruded diets.

Aquafeeds

Replacing fishmeal with DFB in pompano diets

A study evaluated the inclusion of bacterial, dried fermented biomass as a replacement for fishmeal in four practical diets for Florida pompano juveniles. There were no significant differences in final weight, survival, FCR or thermal-unit growth coefficient.

Innovation & Investment

Colombia to diversify its aquaculture industry through marine fish culture

A collaboration among the Center for Aquaculture Research in Colombia, Center for Research, Education and Recreation, and University of Miami is working to adapt the latest aquaculture technology available worldwide to local conditions and create opportunities for farming new commercial species in Colombia.