Technology shows promise in carp, catfish and salmon studies

Ultrasound has numerous commercial applications, including water treatment. LG Sonic ultrasound technology can also be used to suppress algal growth and biofilm formation.

This unique ultrasound system does not use chemicals and needs only a low supply of electrical energy. It does not harm plants, fish, zooplankton or other life present in water, and thus has a low environmental impact.

Ultrasound technology

Unlike lab sonicators or other ultrasound systems, the LG treatment emits via transducers a “blend” of very specific ultrasound frequencies that enhance the specificity and selectivity of the ultrasonic treatment. The specialized transducers translate a much wider spectrum of ultrasound than standard transducers. Without the controlled selectivity they provide, ultrasound can be lethal to aquatic organisms.

In treating algae, for example, ultrasonic sound waves set at precise frequencies directly target the cellular structure of the algae. Resonance, longitudinal and transversal sound wave forces suppress algal growth and reduce biofilm.

To achieve optimal ultrasound irradiation from the transducers into water, the impedance of the transducer housing must match that of the liquid. The larger the difference between the impedance values, the higher the reflection coefficient and less ultrasound is transmitted into the water.

The amount of algae in the water is reduced and controlled in an efficient, cost-effective manner, and further growth is inhibited. The clarity of the water is visibly improved, as well. The continuous use of such a device prevents the water from becoming polluted again.

This technology can be used in all situations where water is stored, from large industrial water applications to small ponds. The amount of time needed to see improvements depends on such parameters as the type of algae present, water temperature, amount of light, amount of nutrients (especially phosphate and nitrate), size and depth of the water body, solids levels, turbidity and retention time.

Carp study

The author’s company carried out Cooperative Research Project-funded research in Europe to study the effects of LG Sonic ultrasound in carp farming in accordance with the European Commission Water Framework Directive that aims to achieve sustainable water use, sustainable management and protection of freshwater resources.

The experiment ran in two 5- x 9- x 0.8-meter ponds, each stocked with 34 common carp. Both ponds had permanent aeration, and the water underwent various filtration steps. The test pond also received ultrasound treatment. Groundwater was added as needed to compensate for evaporation losses.

The results were promising (Table 1). In the pond with ultrasound, average values for bound and free chlorophyll a were 37.3 and 1.5 mg per cubic meter, respectively. In the reference pond, the values were 1,565.6 and 10.6 mg per cubic meter.

Oyib, Average values of physico-chemical parameters, Table 1

| Parameter | Reference Pond | Ultrasound Treatment |

|---|

Parameter | Reference Pond | Ultrasound Treatment |

|---|---|---|

| Temperature (° C) | 13.6 | 15.6 |

| Dissolved oxygen (mg/L) | 9.00 | 8.70 |

| pH | 8.3 | 8.1 |

| Suspended solids (mg/L) | 142.80 | 10.00 |

| Five-day biochemical oxygen demand (mg/L) | 36.70 | 3.10 |

| Total phosphorus (mg/L) | 1.20 | 0.30 |

| Nitrate (mg/L) | 1.40 | 3.10 |

| Nitrite (mg/L) | 0.80 | 0.17 |

| Ammonium (mg/L) | 0.50 | 0.10 |

Although the values for free chlorophyll a were low in both ponds, it was especially low in the test pond. The ultrasound-treated pond was also visually clearer and had noticeable reductions in various water quality parameters.

Catfish studies

In the United States., Dr. Paul V. Zimba of the USDA-ARS Catfish Genetics Research Unit and Dr. Casey C. Grimm of the Southern Regional Research Centre have carried out studies utilizing ultrasound technology in channel catfish production.

Catfish production relies on timely sales of fish, but sales schedules can be hampered by the occurrence of off-flavors and fish mortality from disease. Efforts to control off-flavor have used chemical treatments such as diuron, sodium chloride, hydrogen peroxide, titanium dioxide and copper.

These treatments are effective, but can lead to increases in chemically resistant pathogens in ponds requiring repeated applications that can be labor-intensive and increase production costs. Diseases can result from the presence of bacteria, viruses and fungi in ponds. An alternative to chemical treatments is the use of ultrasound.

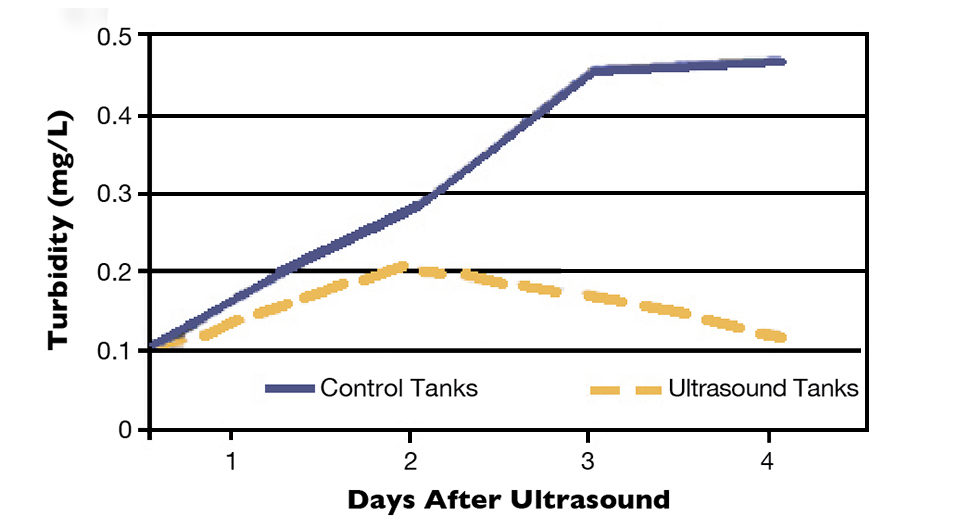

An initial lab study evaluated the effects of LG Sonic ultrasound on catfish feeding and weight gain. Catfish fingerlings stocked at 13 fish per tank were acclimated to four control tanks and four tanks that received ultrasound treatments. Turbidity was decreased by 60 percent in the ultrasound-treated tanks (Fig. 1), and bacterial cell counts were significantly lower in the treated tanks. These results suggested that use of ultrasound could reduce pathogenic bacteria in ponds to levels below those that cause fish mortalities.

Another lab experiment assessed if ultrasound caused greater off-flavor diffusion from water to air. Eight tanks were dosed with 1-ppm 2-methylisoborneol, and four were treated with continuous ultrasound. Samples were collected daily for off-flavor and analyzed using gas chromatography-mass spectrometry. Tanks with ultrasound treatment had significantly (P = 0.09) lower off-flavor levels.

A field study was carried out in 0.47-ha production ponds to assess the impacts of ultrasound on off-flavor and algal biomass. Ponds were stocked with channel catfish fingerlings and operated as growout ponds according to industry standards. Pond conditions were matched in terms of algal density and composition in two control ponds and two ponds treated with ultrasound.

Two ultrasound devices were placed in ponds pointing along the long pond axes. The ultrasound equipment was run continuously from 11 a.m. to 6 a.m., with feeding during the off period. A dense bloom of the cyanobacterium Microcystis c.f. ichthyoblabe Kützing was present in two of the ponds. While dominant in two other ponds, the bacteria was 70 percent lower in overall biomass. Total algal biomass decreased by about 48 percent during the four-week study. Off-flavor concentration was decreased to a lesser degree.

Salmon cage studies

The growth of fouling organisms on suspended fish cages is an impediment to aquaculture projects in coastal waters around the world. Because marine organisms grow on and foul synthetic nets in salmon farming, oxygen available to fish is reduced, and infectious diseases and parasites can spread among the fish.

Antifouling painting for fish cage netting helps reduce fouling, but can be toxic. Furthermore, maintenance of these nets is expensive, time-consuming and often involves the use of toxic products.

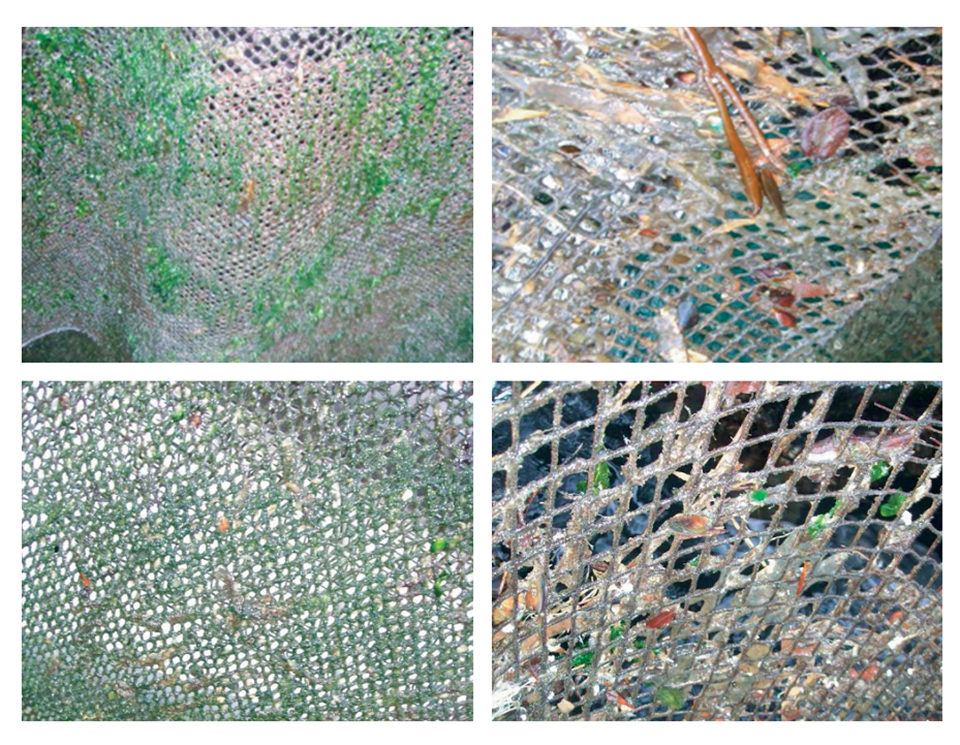

A test to study the reduction of cage net fouling was recently carried out at a salmon-farming facility in southern Chile. An ultrasound system was installed in a 20- x 20-m salmon cage with nets already covered with marine fouling organisms, especially filamentous algae. After 28 days, a clear difference could be seen between the nets of the reference cage and the nets of the cage treated with ultrasound of specific frequencies.

Control nets were heavily covered with filamentous algae and slimy biological substances, compared to the much lower fouling on nets treated with ultrasound. There were no detectable changes in salmon behavior during the trial.

These results suggested that marine fouling on salmon cages can be suppressed with ultrasound, with benefits like less frequent maintenance, less usage of toxic antifouling chemical and lower maintenance cost. Further testing is currently under way.

(Editor’s Note: This article was originally published in the July/August 2009 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Duddy H. Oyib, M.S.

Chief Biologist

LG Sound

Gerrit van der Veenstraat 75

2321 CD Leiden

The Netherlands

Tagged With

Related Posts

Aquafeeds

Algae alternative: Chlorella studied as protein source in tilapia feeds

Chlorella and other species have potential as protein sources in aquafeeds. In trials with tilapia fry raised in a recirculating system, the fish received a fishmeal-based control diet or feeds with portions of the fishmeal replaced by Chlorella.

Innovation & Investment

Algae innovators aim to freeze out early-stage shrimp losses

A greenhouse in Belgium believes its innovative shrimp feed product, made from freeze-dried microalgae, packs the necessary nutrients for the crustacean’s most vulnerable life stage: the first three days of its life.

Health & Welfare

Algae shows promise as alternative DHA source in rainbow trout diets

A growth trial in Canada evaluated the use of algae biomass to increase the concentration of long-chain polyunsaturated fatty acids in the tissues of rainbow trout.

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.