Authors evaluate system to reduce mass discharge of potential pollutants

Treating catfish pond effluents to remove potential pollutants is a difficult engineering problem. Catfish ponds are operated continuously for many years without draining and discharge only after heavy rains or when ponds are drained for renovation. Effluents, while usually dilute with respect to nutrients and organic matter, vary widely in quality over time and among individual ponds.

Wastewater treatment systems for pond effluents would therefore be idle for many more days than they are used. Average annual hydraulic loading to treatment systems would be low, but when discharges occurred, volume could be large for a brief period. The systems must therefore be designed to rapidly treat a large volume of dilute effluent.

Because of difficulties in designing cost-effective “end-of-pipe” treatments, the best way to manage catfish pond effluents is to implement an environmental management system consisting of best management practices (BMPs) that either improve water quality prior to discharge or reduce effluent volume.

Study: BMPs for effluent management

In a study conducted over three years in 2.4-hectare earthen ponds in northwest Mississippi, USA, the authors evaluated an environmental management system to reduce the mass discharge of potential pollutants from channel catfish ponds. Ponds were operated with a multiple-batch fish-cropping system and not drained between crops.

Mass discharge – the product of concentration and volume – is usually more important than concentration alone in determining the impact of an effluent on the environment. The authors therefore chose practices that addressed both factors affecting mass discharge.

Three practices were implemented to reduce the concentrations of potential pollutants: limiting daily feed inputs to 110 kilograms per hectare per day, using a reduced-protein (28 percent) feed, and maintaining a maximum fish density of 18,500 fish per hectare. A fourth practice, “drop-fill” water-level management, was implemented to reduce effluent volume.

In drop-fill water management, pumped water is not added to the pond until evaporation and seepage cause the water to fall to a predetermined level below the elevation of the pond overflow device. At that point, water from a well is added, but only up to another predetermined level well below the point where the pond overflows. With this approach, most rainfall is captured rather than lost as overflow.

Pollutant discharge and fish production from three BMP ponds were compared with those from three ponds refilled to the top of the standpipe every two weeks and managed with no limitation on daily feeding rate. The latter ponds utilized a 32 percent-protein feed and a stocking scheme where 24,700 fish per hectare were added each spring.

Fish production

Average annual fish harvest was 6,425 kilogram per hectare in the BMP ponds and 6,250 kilograms per hectare in the other ponds. The similarity in gross production between treatments was striking, because the stocking rate and maximum feeding rates were greater in the non-BMP ponds. Apparently, even the ponds where BMPs were employed operated near the maximum production capacity for earthen ponds under the conditions of the study.

Effluent quality, volume

Concentrations of total nitrogen, total phosphorus, five-day biochemical oxygen demand, and total suspended solids were only slightly lower in effluents from the BMP ponds relative to the other ponds. Therefore, the feed- and fish-management practices implemented to reduce concentrations of potential pollutants had negligible influence on mass discharge.

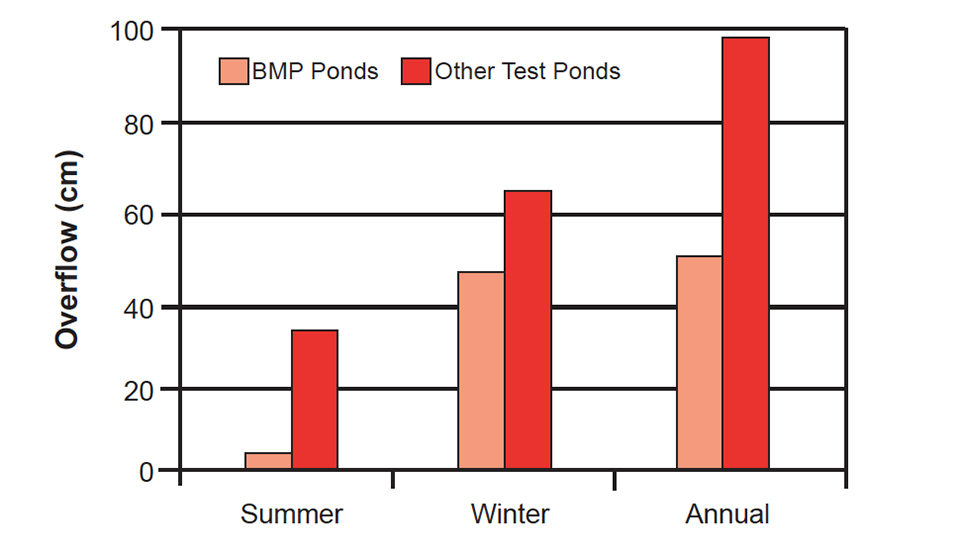

Drop-fill water management was very effective in reducing discharge volume. On average, 50 cm of water overflowed from the BMP ponds each year. About twice that amount overflowed from the other test ponds (Fig. 1). Annual and seasonal overflows varied greatly according to weather conditions. For example, the overflow from BMP ponds was 74 cm in 2001, a particularly wet year, but only 30 cm in 2003, a relatively dry year.

The effect of water-level management on pond overflow was greatest in the summer, because climatic conditions in the summer – high evaporation rates and brief, sporadic rainfall events – were such that drop-fill ponds usually had sufficient storage to capture nearly all rainfall. Winter rainfall is greater and more frequent in northwest Mississippi, and ponds usually stayed near the overflow level for long periods. As such, much of the winter rainfall was lost as overflow from both sets of ponds.

Pollutant discharge

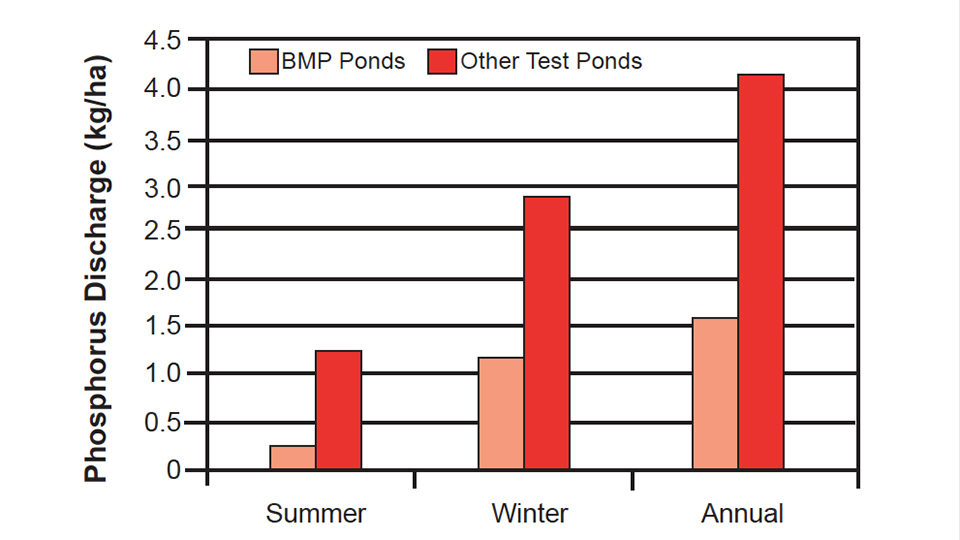

Compared to conventionally managed ponds, the mass discharge of total nitrogen, phosphorus, suspended solids, and five-day biochemical oxygen demand from the BMP ponds was reduced by over 60 percent. Nearly all of the reduction in mass discharge was attributable to reduced effluent volume resulting from water-level management of the BMP ponds.

As with overflow volume, reduction in mass discharge was greatest during summer months. Relative to the non-BMP ponds, total phosphorus discharge from BMP ponds was reduced by over 90 percent during summer months, but only 40 percent in winter months (Fig. 2).

Ground water use

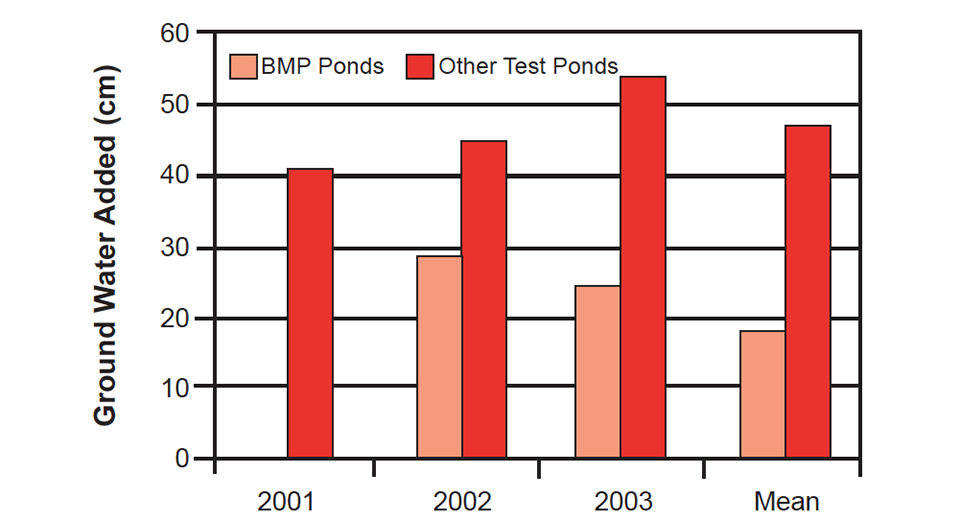

The drop-fill practice was originally developed as a water conservation tool, so it is not surprising the need for pumped water was much lower in BMP ponds. On average, 18 cm of ground water were added to the BMP ponds each year, while 45 cm were added to the other ponds (Fig. 3).

Water use varied greatly from year to year. In 2001, numerous summer rain showers eliminated the need for pumped water in BMP ponds, while 41 cm of ground water were added to the non-BMP ponds. The year 2003 was much drier. On average, 25 cm of ground water were added to BMP ponds, and 55 cm were added to the remaining ponds.

(Editor’s Note: This article was originally published in the June 2006 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Craig S. Tucker, Ph.D.

Mississippi State University

Thad Cochran National Warmwater Aquaculture Center

P.O. Box 197

Stoneville, Mississippi 38776 USA[117,100,101,46,101,116,97,116,115,115,109,46,99,101,114,100,64,114,101,107,99,117,116,99]

-

John A. Hargreaves, Ph.D.

Aquaculture Research Station

Louisiana State University AgCenter

Baton Rouge, Louisiana, USA

Tagged With

Related Posts

Intelligence

Ongoing production issues in shrimp farming, part 1

More R&D and investment is needed to address various ongoing issues in shrimp farming, including genetic improvement, nutritional requirements and feed ingredients, health management and other issues.

Responsibility

Aquaculture effluent partially replaces growing mix for plant production

Aquaculture effluent can be an effective fertilizer in land-based plant production. Research with tilapia utilized dewatered aquaculture effluent (A.E.) as a partial substrate replacement for tomato plant seedlings. Seedling growth decreased when effluent replaced a commercial growing mix at 25 percent or more.

Innovation & Investment

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.

Aquafeeds

Analyzing the hydrostability of shrimp feeds

The physical integrity and nutrient leaching of shrimp aquafeeds are important aspects in their quality control. The water stability of shrimp aquafeeds is often evaluated in various subjective manners. This analytical procedure provides a baseline for the aquafeed manufacturer to assess product quality.