With Aqua-Spark backing, CageEye limits market for feed monitoring system to Norway

Feeding fish is one of the biggest expenses for aquaculture farmers, if not the biggest. Not knowing when a feeding should end results in billions of dollars of fish feed being thrown away, a loss of money and a waste of resources.

“In Norway a conservative estimate is that 7 percent of feed is being wasted, about NOK 1 billion ($119 million),” said Bendik S. Søvegjarto, CEO of Oslo-based CageEye. “That’s a lot of feed and resources to waste and it’s not sustainable.”

Until recently, underwater cameras have been one of few options for monitoring fish behavior. They have, however, significant shortcomings, said Søvegjarto.

“You can get some behavioral information from cameras, but you have a very limited field of vision and the results are very subjective,” he explained. “There’s also the option of tagging every fish to measure its behavior, but that’s very expensive.”

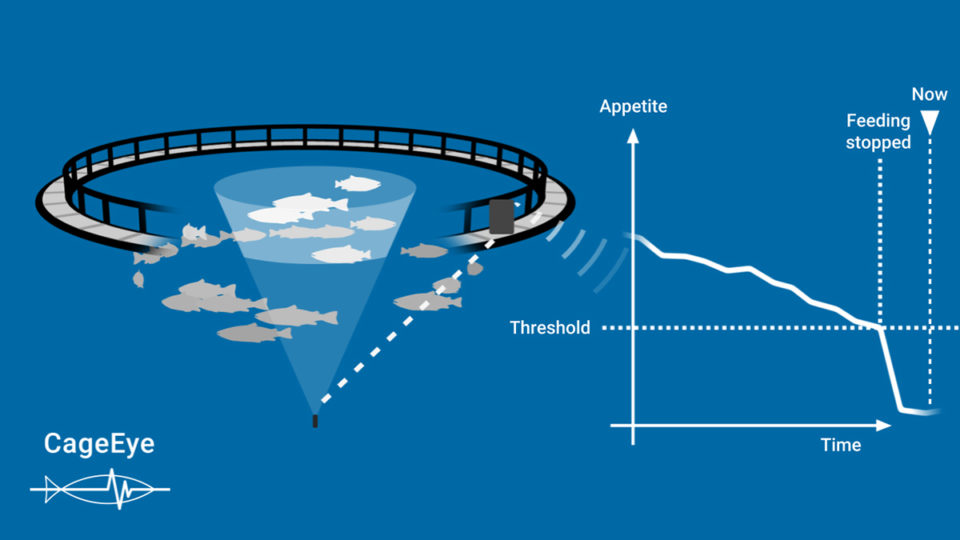

Last year CageEye launched a product that offers an innovative solution: using machine learning and hydroacoustics to objectively measure the appetite of fish in sea cages. The company has taken on its first group of Norwegian salmon-farming customers but is stalling interest from other producers in Canada, Chile and Tasmania.

We’re seeing a shift in the industry where farmers are becoming more open to data-driven approaches.

For now, CageEye is limiting sales as it focuses on more research and development, a luxury afforded partly to a recent investment by Dutch impact investment fund Aqua-Spark, which focuses strictly on aquaculture and related businesses. This brings CageEye’s fundraising total to €5.3 million ($6 million), meaning it has the financing it needs for continued R&D, said Søvegjarto.

Improving feed efficiency by addressing feed loss has been a portfolio priority for Aqua-Spark since its inception because it represents the greatest challenge for any fish farm, said Mike Velings, founder and managing partner at Aqua-Spark.

“Until now we didn’t have anything in our portfolio that focused on open water cage operations, so we were really happy to learn about CageEye a year ago,” he said. “With CageEye we’re able to support improvements in cage farm management, including how feed is distributed. Our investment will help expand their sales and operations and we believe they have the potential to become a technology supplier for many open-water aquaculture operations, not just for salmon. We’re excited to see how their behavior assessment technology will impact other areas of farming as the company matures.”

That maturity has been a steep climb over the past four years. Søvegjarto was studying hydroacoustics instrumentation at the University of Oslo in 2014 when he was recruited by Joakim Myrland, one of CageEye’s founders and a previous student at the university. At that time CageEye was one year old and far from its goal of establishing echo-sounder technology to track biomass movements in a cage and use machine learning to objectively assess the fish’s appetite from this behavior.

Søvegjarto was tasked with building the next generation of hardware for the technology, and within two years CageEye was supplying some equipment for commercial trials in Norway. When the product was launched in 2017 the market response was much stronger than expected, he said.

“We expected some interest in our solution, but not for our stand at Aquanor in Trondheim to be so packed that people had to pass and return multiple times in order to talk with us!” he said. “We now have customers along the whole coast of Norway. But we’re holding back on more sales because we don’t want to sign more customers than we can provide support to.”

CageEye expanded its team from four to 22 in the past 18 months and now has researchers in Oslo, Germany, Australia, the Ukraine and Norway. Its customers lease the technology on a per-cage basis but CageEye only accepts customers willing to use its services for their full sites. Customers receive one or two hydro-acoustic sensors per cage, which are placed below their feed spreader and measure the fish density around the spreader. A measuring box is situated by the railing of a cage and all further processing is done on a barge and in the cloud.

“With this sensor we create an assessment of the fish’s appetite,” Søvegjarto said. “Basically, it’s a tool to get an objective measurement of what is happening while you’re feeding – an analysis of the fish’s behavior.”

Aquaculture farmers log into a dashboard to see the behavior of their fish in real time and make instant decisions on prolonging or terminating feeds. CageEye’s sensors predict when to feed the fish and provide data on when the fish are sated. The result is a more sustainable use of fish feed for farmers with less waste.

Søvegjarto refused to disclose the cost of CageEye’s technology but said it is a little more expensive than the underwater cameras. He insisted that it delivers superior results.

“From their behavior you can tell if the fish are unwell, if they’re hungry or if they’re sated. You have information available to measure their welfare, data that is opening up other worlds for us,” he said.

CageEye also has the ability to fully automate fish feed dispensing based on the data received from its sensors. Søvegjarto said the sensors allow the fish to control the feeding and remove feed operators from the equation.

“Multiple farmers are asking us for this functionality but we’re holding back until we feel the time is right,” he said. “We’re seeing a shift in the industry where farmers are becoming more open to data-driven approaches.”

While pellet detectors also feed fish automatically, they cannot discern if the fish are really hungry, or if the system is malfunctioning. By contrast, with CageEye’s echofeeding algorithm, data is received multiple times per second to continuously determine the status of the cage.

“If something looks out of the ordinary the meal will automatically stop,” Søvegjarto said.

Follow the Advocate on Twitter @GAA_Advocate

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Lauren Kramer

Lauren Kramer is a freelance journalist residing in Richmond, B.C., who has written extensively about seafood marketing for SeaFood Business magazine and SeafoodSource.com. Her work appears in a number of publications, including the National Culinary Review and Flavor & The Menu.

Related Posts

Innovation & Investment

JALA engineering innovation for Indonesian shrimp farmers

A company in Indonesia hopes the vast network of shrimp farms throughout the country will adopt its IoT device, particularly when they’re on the go.

Innovation & Investment

If it’s broken, fix it: Startup takes on shrimp industry in India

A serial tech entrepreneur and a shrimp trader want to be Amazon for India’s shrimp farming industry. An accelerator program half a world away has brought them closer to their goals.

Innovation & Investment

One fish, two fish: Counting technology nets funding for Canadian engineering firm

XperCount, aka the “magic bucket,” uses optics and photonics to deliver 95 percent accurate count of microorganisms, such as fish or shrimp larvae, in just seconds.

Innovation & Investment

Aquaculture data-collection app provides cloud coverage

Aquanetix, launched by two fish biologists, employs cloud technology for electronic data collection, enabling farmers to monitor infrastructure, minimize feed losses and make informed operational business decisions based on real-time reports about their stocks.