Keynote speaker Peer Ederer urges greater, more nutritious food production – including meats and fish – in sub-Saharan Africa and South Asia

With a growing global population expected to reach 10 billion people in the next three decades, efficient and sustainable food production is and will be crucial. Producing roughly double the amount of food being produced today is the “most fundamental challenge we face,” according to Peer Ederer of the Global Food and Agribusiness Network, who delivered the keynote presentation at the Global Aquaculture Alliance’s GOAL conference on Oct. 6.

Ederer’s remarks, delivered on the balcony of his home overlooking Switzerland’s Lake Zurich, were part of the first-ever virtual GOAL. Originally scheduled to take place in Tokyo, GOAL was forced online due to the coronavirus pandemic, which has upended international seafood trade and has curtailed traveling.

The pandemic has only heightened the importance of leadership in shaping the food systems of tomorrow, said Ederer, who told the online audience that not only is more food production necessary, but we need “better food” produced where it’s needed most. And that includes animal protein, he stressed, singling out sub-Saharan Africa and South Asia as two areas where food security is most in question.

No other topic is more important on this planet than how we will produce our food.

“Even with technological advances, it’s not enough to close the food gap” in these places, Ederer said. But the solution to closing the gap is not eliminating animal-sourced foods like meats, fish, dairy and egg products.

“Eliminate those foods, we can reduce our food consumption and make the equation work – that is the common, standard reasoning. But it is fundamentally flawed,” he said. “The food gap is not uniformly distributed around the world. Developed or rich countries have no gap. We need to produce food where there are gaps – really, there is no other solution than to produce more food in those countries and regions that need it. Switching to vegan diets contributes nothing to the food crisis.”

Ederer also identified “rich ag” and “poor ag” as the delineating factor between efficient and non-efficient animal protein production. Pointing to beef, Ederer said there are more cattle in Ethiopia and Sudan than in the United States, yet the U.S. cattle and dairy industries are many times more productive. “We should focus on increasing productivity on the parts of the food system that are not productive,” he said. “And let’s fight this war together, instead of pointing fingers at other animal sectors.”

The needed food-production increases should not be considered on terms of calories, but rather nutrients, said Ederer. In 2020, he added, every third child worldwide under the age of 5 experiences physical or mental stunting due to malnutrition or obesity: “It’s not that we don’t have enough calories; it’s poor nutritional content.”

What’s more, livestock animals consume resources that are not fit for human consumption, such as grasses and processing byproducts. By reducing animal-sourced foods, Ederer said, those resources would not be made available to the food system. “The accounting does not add up – we cannot replace animal-sourced foods until we are guaranteed another supply with the same richness of nutrients,” he said.

Regarding climate, Ederer argued that the best and only technologically feasible way to reduce carbon dioxide is carbon sequestration through agriculture and aquaculture. “It’s the only technology we have that can sequester carbon back into the soils. It’s a bridge for the next couple of decades,” he said.

Finally, living with animals and making them part of human civilization has cultural benefits, he said, and by discarding animal-sourced foods we could discard the cultural vales that go with them. “It teaches us to be disciplined, reliable, timely, to have functioning markets, to have trust in the system. There are a lot of virtues [required] to develop an agriculture and aquaculture system, and it rubs off into other areas. The value of agriculture is often very much underestimated.”

Ederer urged GOAL attendees to pay attention the United Nations’ Food Systems Summit in 2021, scheduled for New York City.

“The 2020 decade, I believe will be the decade when we transform our global food systems,” Ederer said. “I encourage you to get involved. No other topic is more important on this planet than how we will produce our food, and there has never been a more important time.”

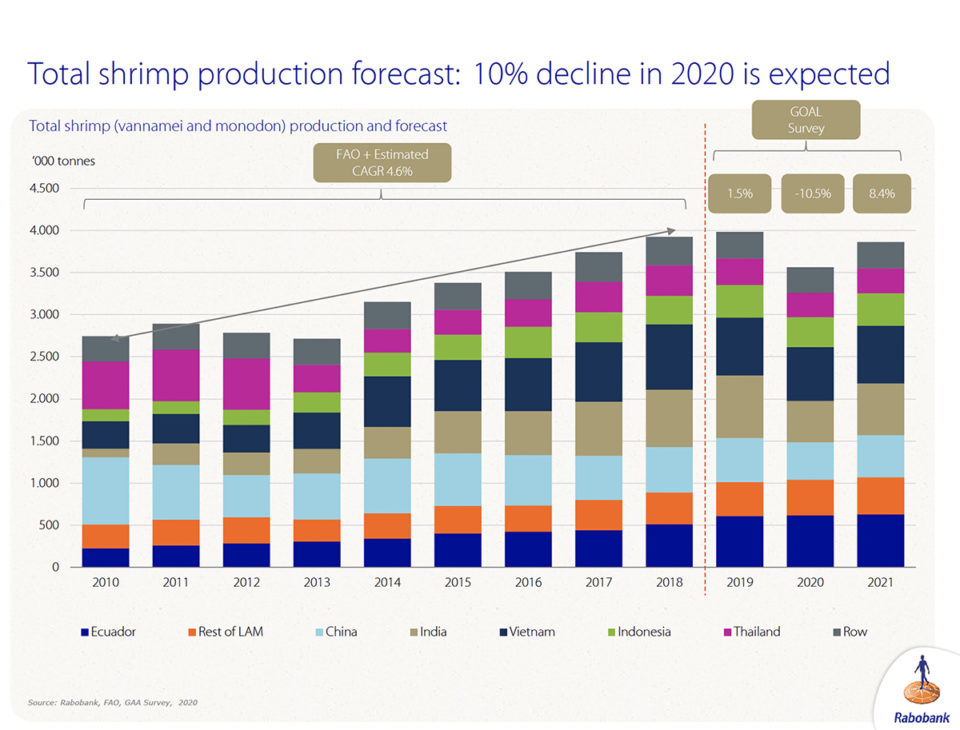

Shrimp production will be down 10% in 2020

Global shrimp production is forecasted to drop 10 percent in 2020, according to GAA’s annual Global Shrimp Production Forecast and Survey, delivered in partnership with Rabobank Resources for the first time.

The coronavirus pandemic is one of the primary factors in the decrease, according to Gorjan Nikolik of Rabobank, who presented the survey findings for both shrimp and finfish. But the shrimp data he presented also factored in some far less bullish outlooks than had been a factor in past surveys.

(Editor’s Note: GAA members can access all video presentations and PDFs of the survey findings on the GOAL website.)

For instance, the data was presented in two ways: one using figures from the Food and Agriculture Organization of the United Nations (FAO) and also with estimates from leading industry sources like Robins McIntosh, senior VP at Charoen Pokphand Foods in Thailand. McIntosh shared far lower production levels than what FAO has reported for China and Indonesia, in particular.

Whereas FAO showed China’s shrimp production to be growing at a compound annual growth rate of 4.9 percent from 2010 to 2018, McIntosh said the trend was in the opposite direction, a 4.8 percent decrease over the same period.

The GOAL survey data for Indonesian shrimp production shows a similar growth rate than did the most recent estimate from FAO (12 percent and 11.5 percent CAGR 2010-2019), the GOAL data is starting from a much lower point, less than 150,000 metric tons (MT) as opposed to nearly 400,000 MT from FAO.

It shows how difficult the task is to compile accurate numbers on a year-to-year basis, said Nikolik. However, the comments and insights that GAA and Rabobank received this year showed that despite the worries from COVID-19, the outlook is bright for next year. In fact, he singled out Brazil as the country to watch as an emerging player in the shrimp industry.

“They have better genetics, feeds and microfinancing driving growth,” he said. “Everyone should be watching Brazil very closely, as they are already a global ag powerhouse.”

New production paradigms shine

Offshore aquaculture will drive future growth of Norway’s world-leading salmon-farming industry, according to SalMar Chairman Alte Eide. In fact, 70 percent of the growth between now and the year 2050 will be offshore, he predicted. Norwegian salmon production was 1.335 million MT in 2019, and the country is targeting 5 million MT in three decades. This growth will add about 130,000 jobs to the sector as well, he said.

“We’ll need that kind of growth to feed an ever-increasing global population,” he said. “It is environmentally and ethically indefensible not to develop and grow [aquaculture].”

Eide gave GOAL attendees an inside look at the early successes of the company’s massive Ocean Farm 1 and its plans for a newer system that he called Ocean Farm 2, or the “Smart Farm.”

“We decided to go from big to bigger,” he said, building a farm that can withstand open-ocean wave heights of 31 meters. Ocean Farm 2 will be 70 meters tall (Ocean Farm 1 is 68 meters tall), 160 meters in diameter (up from 110 meters) and hold more than 3 million fish (Ocean Farm 1 holds less than 1.5 million fish).

It’s about control, total control. It’s always been the key to successful farming.

“With 20,000 sensors providing unique insights into the life of a farmed salmon, we achieved biological performance we could only dream of,” he said, adding that the industry must invest about 200 billion NOK in offshore equipment to achieve his vision.

“When you said, ‘We will go offshore,’ it was like JFK [President John F. Kennedy] saying, ‘We will go to the moon,’” remarked moderator George Chamberlain, president of GAA, after Eide’s presentation.

While salmon is the focus of many new production innovations, shrimp is as well. Robins McIntosh of CP Foods is also CEO of Homegrown Shrimp USA, which has built its first shrimp hatchery in Florida and has plans for several more in the United States and other markets, all of which will be built in close proximity to multiple metropolitan areas.

McIntosh talked about the difficulty of producing shrimp in recirculating aquaculture systems (RAS), which has been associated with high mortality, high feed-conversion ratios and high costs. The systems that Homegrown Shrimp has designed allow for culture anywhere, with zero water discharge and high survival rates.

“It’s about control, total control. It’s always been the key to successful farming. Outdoors, you never have total control,” he said.

While the hatchery in Indiantown, Fla., is operational, it is using biofloc technology for greater consistency but will soon be reoutfitted for RAS. “With biofloc, we can get 24 kg per square meter per year – with RAS that would be closer to 100,” McIntosh said. While the business will soon include its own restaurants to serve its own product, for now the facility is selling postlarvae to small growers. McIntosh expects the first fully operational farm to be supplying fresh shrimp next year.

Also, as the Homegrown Shrimp business grows, McIntosh said he’ll be on the lookout for younger workers who don’t come to the business with a lot of preconceived notions about what works and what doesn’t.

“The new generation was brought up to say you can can do this, in the United States, efficiently and at lower costs,” he said.

Also featured during the conference was the high-tech Pure Salmon RAS system – featured in a recent Advocate article – and Vietnam shrimp producer Minh Phu’s 2-3-4 shrimp farming technology, which includes a 4,500-meter pipeline that feeds fresh seawater into the system, which the company claims can produce 450 MT per hectare per year, with no antibiotics or chemicals.

SRS is ‘our COVID-19’

Wrapping up Day 1, animal health and welfare experts discussed the use of antibiotics in animal food production, as well as other potential stress points like the handling of fish, feeding regimes and stocking densities.

Christine Huynh, director at Nautilus Collaboration Pty. Ltd. in Australia, said the best animal husbandry practices are proactive, not reactive. But when asked by session moderator George Chamberlain of GAA about how a veterinarian views antibiotics, she agreed that it’s often in the animal’s best interests to treat.

“Antibiotics are controversial,” she said. “There are two aspects that apply to welfare. If there is a disease you need to treat, [especially] if there are adverse effects from that disease. It’s also an ethical response to treat. But we need to practice prudent use. It’s an important tool but it can’t be abused.”

Huynh referred to OIE (World Organisation for Animal Health) guidelines for use on antimicrobials – “be aware of them and follow them,” she said – and to be sure to make clear-cut diagnoses before treatments. Huynh also urged finfish producers to revisit their stocking densities after each production cycle.

Rolando Ibarra of the Monterey Bay Aquarium talked about the organization’s efforts to help Chile’s salmon farming sector reduce its dependence on antimicrobials. The industry’s worst enemy is SRS – salmonid rickettssial septicaemia, or piscirickettsiosis – and Ibarra said it’s long been a challenge for the industry to control.

“It’s our COVID-19,” he said. “Without a vaccine it’s very difficult to control. It’s an endemic disease in Chile” that antibiotics does not solve.

Ibarra said progress is being made, however, as collaboration increases not only between companies but within companies themselves. He also called for increased regulation and to “place correct incentives” for industry adopting greater controls. Ibarra and the Monterey Bay Aquarium are working on a project called CSARP (the Chilean Salmon Antibiotic Reduction Program), which will be the subject of an upcoming Advocate article. CSARP is setting a target of a 50 percent reduction in antibiotic use in Chile’s salmon sector by 2025.

McIntosh of CP foods and Loc Tran of ShrimpVet in Vietnam also discussed the prevalence of shrimp diseases in various countries and spent a good amount of time talking about what causes white feces syndrome. EHP – enterocytozoon hepatopenaei – and bacteria both can cause the condition, said Tran, but when combined the results can be catastrophic.

“EHP white feces you don’t cure,” said McIntosh. “The other can go away.”

Follow the Advocate on Twitter @GAA_Advocate

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Aquaculture Alliance

Portsmouth, NH, USA[103,114,111,46,101,99,110,97,105,108,108,97,101,114,117,116,108,117,99,97,117,113,97,64,116,104,103,105,114,119,46,115,101,109,97,106]

Tagged With

Related Posts

Innovation & Investment

Robins McIntosh: Florida RAS shrimp farm the first of many

CP Foods’ Robins McIntosh is turning a 40-acre site in Florida into a next-generation shrimp farm, producing 1,000 tons annually with zero waste.

Health & Welfare

EHP a risk factor for other shrimp diseases

Laboratory challenges and a case-control study were used to determine the effects of EHP infection on two Vibrio diseases: acute hepatopancreatic necrosis disease (AHPND) and septic hepatopancreatic necrosis (SHPN).

Intelligence

10 takeaways from GOAL 2019 in Chennai, India

The Global Aquaculture Alliance held its GOAL conference in Chennai, India, and recruited a host of experts in various fields to share their expertise.

Innovation & Investment

A salmon farm in Dubai, because of course

Last year Dubai-based Fish Farm LLC sold the first batch of salmon to be born and bred in the United Arab Emirates. More are certainly coming.