Biological composition, physical properties

After my previous articles on high-pressure processing (HHP) in the Global Aquaculture Advocate, several individuals expressed interest in applying the technology to eastern oysters (Crassostrea virginica), but were unwilling to make the necessary capital investment to establish HPP systems unless further documentation could justify the required expenditure.

Most inquiries concerned how HPP affects microbial populations, shelf life, sensory appeal, and some physical properties. Several individuals believed HPP could create a marketing problem, since postprocessing drip loss was reported to increase during distribution and storage.

In order to gain accurate information on these issues, the Virginia Fishery Resource Grant program awarded a grant to the High-Pressure Processing Laboratory and Service Center at Virginia Tech in Blacksburg, Virginia, USA, to study how HPP treatments affect the physical and biological properties of eastern oysters. Results from the study showed that some of the issues raised by oyster producers and processors were valid, but others were unfounded.

Study setup

For the study, fresh oysters were obtained from a commercial grower per producer per processor during the summer and fall and subjected to 275 MPa (40,000 psi) for 30 seconds, 275 MPa for 60 seconds, or 310 MPa (45,000 psi) for 30 seconds. A control group, which received no pressure processing, was also included in the study.

The pressure-treated oysters were blown for five minutes and placed on a skimming table for three minutes prior to packing. The oysters were stored at 4 degrees-C and analyzed after two, five, 10, 15 and 20 days. The study was replicated three times.

Vibrio vulnificus reduced

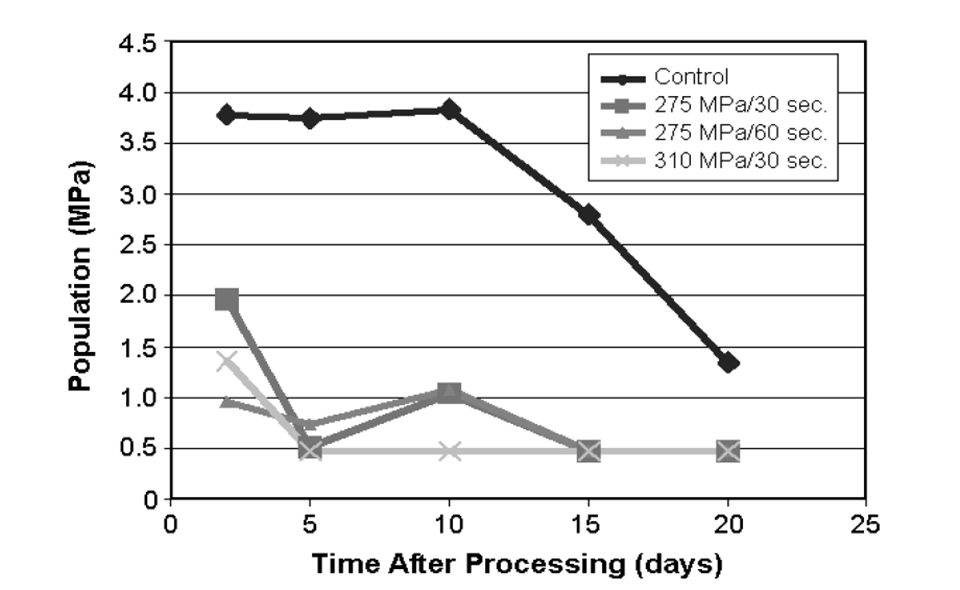

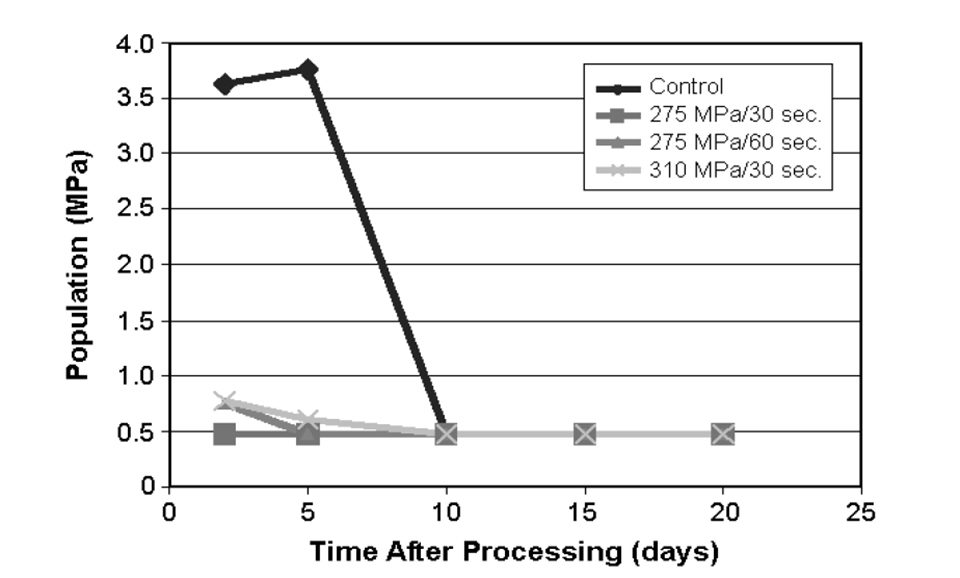

All three HPP treatments resulted in substantial reductions in Vibrio vulnificus populations, with the greatest reduction in summer-processed oysters (Figs. 1 and 2). Interestingly, those organisms that survived the initial HPP treatments continued to die off after five days of refrigerated storage. The reduction during storage was probably due to the cold temperatures, perhaps compounded by cell injury resulting from HPP treatment.

By the fifth day, the populations were either non-detectable or measured at less than 10 per gram, which is insufficient to cause illness. Since most oysters are probably consumed after five days of processing, illness through V. vulnificus should not occur unless oysters are recontaminated through postprocessing exposure.

Shucking

High-pressure oyster processing can reduce the need for manual shucking by releasing the adductor muscle from the shells of the animals. All three treatments decreased the percentage of unshucked oysters from 100 percent in the control to 10 percent or less (Table 1). More than 80 percent of the oysters were partially shucked when treatment was complete.

Flick, Shucking effects on oysters, Table 1

| None | Partial | Full |

|---|

None | Partial | Full | |

|---|---|---|---|

| Control | 100% | 0% | 0% |

| 275 MPa/30 sec. | 10% | 83% | 7% |

| 275 MPa/60 sec. | 0% | 95% | 5% |

| 310 MPa/30 sec. | 0% | 87% | 13% |

Processing pressures had a greater effect than processing time on the number of oysters that were fully shucked. Oysters that were partially shucked received less damage during hand shucking, which reduced the need for skilled labor and therefore lowered labor costs.

Drip loss

Maintaining low drip loss in shucked oysters is essential to maintain product quality as well as economic value. Many institutional buyers have purchase requirements that shucked oysters may not have a drip loss over 10 percent.

Drip loss was shown to increase with the use of HPP treatments (Table 2). There was a substantial difference in drip loss between fall and summer oysters. Fall oysters had drip loss slightly above 10 percent by the 10th day of refrigerated storage. However, summer oyster drip losses ranged 13 to 15 percent by the fifth day of storage and 17 to 19 percent by the 10th day.

Flick, Drip loss of oysters treated with HPP, Table 2

| Season | Treatment | Storage Time (days) 2 | Storage Time (days) 5 | Storage Time (days) 10 | Storage Time (days) 15 | Storage Time (days) 20 |

|---|

Season | Treatment | Storage Time (days) 2 | Storage Time (days) 5 | Storage Time (days) 10 | Storage Time (days) 15 | Storage Time (days) 20 |

|---|---|---|---|---|---|---|

| Summer | Control | 6.2% | 13.0% | 17.9% | 17.8% | 20.3% |

| 275 MPa/30 s | 9.2% | 15.2% | 19.1% | 24.8% | 20.2% | |

| 275 MPa/60 s | 10.9% | 13.2% | 17.5% | 21.9% | 23.0% | |

| 310 MPa/30 s | 9.9% | 15.2% | 17.2% | 24.6% | 23.6% | |

| Fall | Control | 5.0% | 5.52% | 4.4% | 6.5% | 9.6% |

| 275 MPa/30 s | 7.2% | 7.5% | 10.5% | 9.0% | 13.1% | |

| 275 MPa/60 s | 4.6% | 9.4% | 11.5% | 7.4% | 15.1% | |

| 310 MPa/30 s | 5.0% | 9.2% | 9.5% | 7.0% | 13.3% |

The difference in drip loss in summer oysters between day 10 and 20 ranges 1 to 6 percent. Most of the drip loss occurs between the second and 10th days after processing. Obviously, processors that use HPP treatments have to make business decisions on how to market their oysters during the summer because of the excessive drip loss.

During the next 18 months, a study will be implemented to determine the economics associated with HPP treatments and shucking, oyster yields after shucking, and drip losses during storage. Both fall and summer oysters will be included, as well as Gulf and Atlantic Coast oysters.

Color

High-pressure processing did not greatly affect the initial color of the oysters or their color over the shelf life of the study. Observations by a small panel experienced in oyster products noted that the oysters treated with HPP had a slightly whiter coloration than the control. The white color could be an indication of some protein denaturation during the HPP treatments, because the pressure resulted in a temperature increase of 12 to 14 degrees-C.

Odor

A sensory study measuring differences in odor showed no differences between treatments, including the control, until the 15th day of storage. At day 15, changes in odor were observed in the control, 30-second 275-MPa treatments, and fresh oysters. After 20 days, all treatments had a fresher odor than the control. This suggested HHP can extend the time for which oysters are considered fresh.

(Editor’s Note: This article was originally published in the February 2005 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

George J. Flick, Jr., Ph.D.

Food Science and Technology Department

Virginia Tech/Virginia Sea Grant (0418)

Blacksburg, Virginia 24061 USA

Tagged With

Related Posts

Intelligence

Aquaculture has put the oysters back in Oyster Town

Whitstable Oyster Fishery Co. aims to safeguard the English town’s rich oyster tradition. Farming triploid oysters on racks in intertidal zones has made a "massive difference," says the company's managing director.

Responsibility

A helping hand to lend: UK aquaculture seeks to broaden its horizons

Aquaculture is an essential contributor to the world food security challenge, and every stakeholder has a role to play in the sector’s evolution, delegates were told at the recent Aquaculture’s Global Outlook: Embracing Internationality seminar in Edinburgh, Scotland.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Intelligence

A model for estimating pathogen variability in shellfish

This study reports on the development of a mathematical model for the shellfish depuration process and its impact on norovirus levels found in shellfish.