Short-term accumulation of inosine monophosphate contributes to pleasant flavor

Prolonging freshness and delaying seafood spoilage are major challenges facing both the wild-caught and aquacultured seafood industries. Fish “freshness” is estimated by a combination of sensory attributes: appearance, smell, texture, and taste. Sensory evaluation by trained experts is an accurate way to measure freshness.

Quantitative chemical, biological, and instrumental techniques are correlated with sensory qualities to evaluate fish freshness and quality attributes. In postmortem fish, intrinsic chemical and physical changes due to endogenous enzyme activity and extrinsic changes due to microbial growth and metabolism cause losses in fish freshness and quality attributes.

Postmortem changes

The deteriorative changes that start at the point of death are impacted by preharvest conditions that exhaust energy reserves in the muscles of fish. The most dramatic change is the onset of rigor mortis.

At death, fish muscles are completely relaxed with an elastic texture that persists until they begin to contract. When muscles become rigid, the fish enters rigor mortis that can last for hours until it is resolved by the action of endogenous proteases, which attack various structural muscle proteins. Resolution of rigor mortis makes the muscles relax, but they are not as elastic as before rigor. The rate in onset and resolution of rigor varies among species and is affected by fish temperature, handling, size, and physical condition.

Freshness values

Using natural autolytic changes in muscle, researchers have developed a formula for fish freshness defined by “K” values. The K or “freshness” values give a relative freshness rating based on the enzymatic breakdown of adenosine triphosphate (ATP) to adenosine diphosphate (ADP) and inosine monophosphate (IMP).

Short-term accumulation of IMP contributes to pleasant fresh fish flavor, an indicator of high quality and freshness. In latter stages of rigor, the breakdown of ADP and IMP results in the accumulation of inosine and hypoxanthine, which reflects poor quality.

The ratio of inosine and hypoxanthine to ATP and its catabolites forms the K value. The higher the K value, the lower the freshness level. The onset of rigor and gradual loss of the sweet, meaty flavor of very fresh fish is directly related to autolytic changes caused by endogenous enzymes.

Spoilage organisms

Microorganisms proliferate on the skin, gills, and intestines of live and harvested fish. The total viable counts of the microorganisms vary from 102-107 colony-forming units (cfu) per centimeters on skin surfaces to 103-109 cfu per centimeters on the gills and intestines.

Until death, fish flesh is sterile. When fish die, their natural immune systems collapse and allow bacteria to colonize the flesh. Fish spoil at various rates, and the types of microorganisms present vary depending upon storage conditions.

There is a distinction between the bacteria on fish when they spoil and the spoilage-specific organisms responsible for the development of off-odors and off-flavors. By identifying the spoilage organisms, scientists have developed microbial growth models to predict the shelf life of fresh fish based on growth of individual bacteria responsible for off-odor and off-flavor development.

Biochemical changes

Studies show that bacteria produce most of the volatile compounds characteristic of fish spoilage. These compounds include trimethylamine (TMA), sulphur compounds, aldehydes, ketones, esters, hypoxanthine, and other compounds with low molecular weights. Substrates for the production of volatiles include carbohydrates like lactate and ribose, nucleotides such as inosine monophosphate and inosine, and other nonprotein nitrogen compounds. Amino acids are important substrates in the formation of sulphides and ammonia.

Many spoilage organisms in fish utilize trimethylamine oxide under anaerobic conditions. The reduced component TMA is one of the dominant fish spoilage components that cause the characteristic fishy odor. The level of TMA in fish varies between species, but is typically 10-15 mg TMA-omega per 100 g in aerobically stored fish and about 30 mg TMA-omega per 100 g in packaged fish – the level at which consumers reject fish based on sensory evaluation.

Sensory, QIM quality evaluations

The need for quantitative evaluations of fish quality has led to grading schemes based on fish freshness and deterioration. After evaluating the appearance, odor, outer slime, eyes, gills, and belly cavity of whole and gutted fish, the fish are graded as Extra (E), A, B or Unfit (C). The disadvantages of these sensory schemes are that remaining shelf life can not be obtained directly from the freshness grades. The quality index method (QIM) is rapidly being adopted as an alternate sensory technique using quality attributes evaluated in sequence.

Since all fish have their own distinctive spoilage patterns and sensory attributes, QIM schemes must be developed for individual species. Each attribute is scored 0-3 by novice or experienced assessors with low scores indicating the best quality. The sum of all demerit points yields a QIM index value, which increases linearly with storage time. The linear relationship between the quality index and the storage time on ice makes it easy to calculate the remaining shelf life of fish.

Preserving quality, extending shelf life

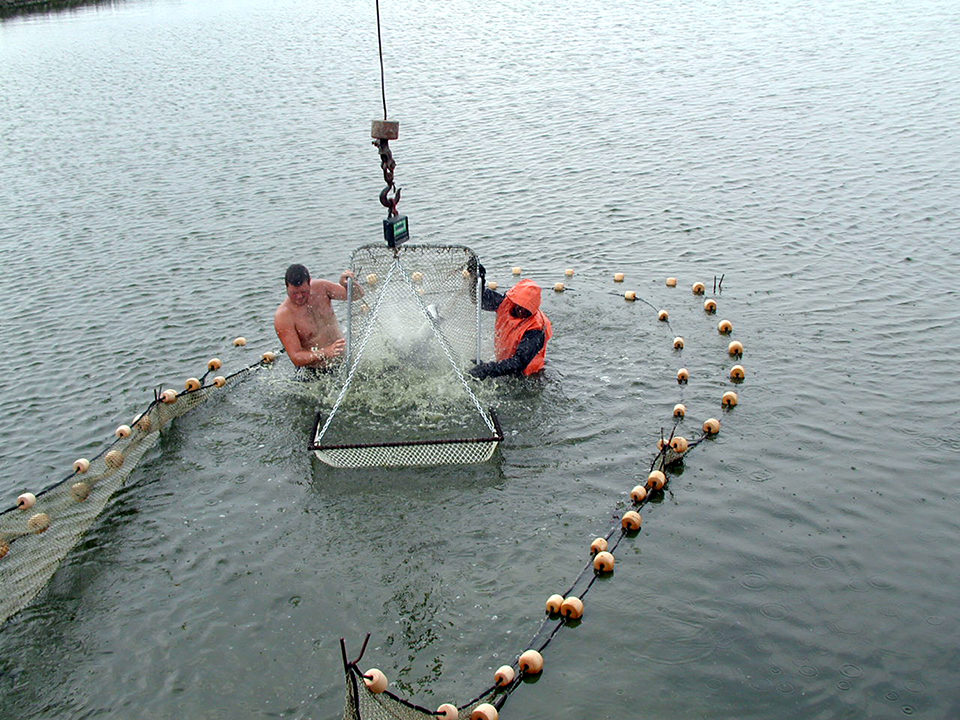

Microbial activity is responsible for most fish spoilage. Temperature remains the principal control measure to preserve fish quality. Rapid chilling at point of harvest can significantly improve the shelf life of fresh fish, but the extent of improvement depends on numerous factors, including species, harvest methods, and environmental conditions.

Delaying the onset of autolytic reactions and growth of microorganisms associated with fresh fish gives the greatest extension in shelf life of fresh fish. “Rested harvest,” a concept developed at the Crop and Food Research Institute in New Zealand, is based on this principle. In this method, food-grade anesthetics reduce the stress on fish at time of harvest to lower the loss of energy reserves in the live fish, delay the onset of rigor, and extend its duration several days. If used incorrectly in transporting live fish and harvesting salmonids, the anesthetic can leave a residual odor.

The optimal eating quality of fresh fish on ice, which occurs about two days after the resolution of rigor, is closely related to the temporary build-up of IMP in muscle tissues. Delaying and extending the time fish muscle is in rigor effectively preserves quality and extends shelf life.

Bleeding fish prior to or at the point of death is another effective technique to preserve freshness. The “ikejime method” is used for spiking large tuna to destroy the neural network between the brain and spinal column. In combination with temperature, this can be very effective in reducing discoloration and the development of off-flavors.

High-pressure processing and modified atmospheric packaging are other techniques used to reduce enzymatic activities and eliminate bacteria in seafood products. High-pressure processing applied to the shucking of raw oysters eliminates pathogenic bacteria. Modified atmospheric packaging has expanded markets for fresh prepackaged fish fillets and portions.

Both technologies retard or eliminate natural autolytic enzyme activities or reduce the growth of spoilage microbiota present in fresh fish. The successful application of these techniques, however, depends upon the preharvest history of products well before the fish reach the processing steps.

(Editor’s Note: This article was originally published in the September/October 2006 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

David Green, Ph.D.

North Carolina State University

Seafood Laboratory

303 College Circle

Morehead City, North Carolina 28557 USA -

Pamela D. Tom, M.Sc.

University of California, Davis

Sea Grant Extension Program

Food Science and Technology Department

Davis, California, USA

Tagged With

Related Posts

Intelligence

Adding value to tilapia to tap into U.S. market

New markets for tilapia and expansion of existing ones can be created by planning and implementing properly designed geographic strategies to meet discriminating consumer preferences. Low labor costs in most producing countries promotes value-adding by the production of fresh fillets.

Health & Welfare

Aquaculture of Amazon fish in Latin America

Many fish species that live in the Amazon basin have great potential for aquaculture. The main species currently cultured in the region is tambaqui, a fast-growing, omnivorous fish that tolerates poor water quality.

Health & Welfare

Building a better shrimp nursery, part 3

Shrimp nursery systems offer significant potential for compensatory growth after juveniles are transferred to ponds for final grow-out. Nursery feed selection and their management are critical components of shrimp nursery systems.

Innovation & Investment

Caribbean producer aims to make a name for sutchi

Pangasius farmed in the Dominican Republic? True story. Value Aquaculture, with partners hailing from Germany and Chile, is trying to get U.S. buyers to take a fresh look at the Mekong catfish species.