Contained environments support research, commercial potential

In the United States, oysters are exclusively harvested and farmed in brackish rivers, estuaries, bays and oceans. The Eastern oyster (Crassostrea virginica) industry is an important multi-million-dollar industry that brought in nearly $100 million in 2009. However, the total landings in the U.S. dropped significantly over the past 60 years, from approximately 31,750 metric tons (MT) to 11,340 MT.

Numerous issues contributed to this decline, including overharvesting of stocks, loss of habitat, predation by cow-nosed rays and other species, and disease outbreaks due to Perkinsus marinus and Haplosporidium nelsoni. The oyster industry also faces numerous other challenges from anthropogenic pollutants, climate change, harmful algal blooms and various viral, bacterial and parasitic pathogens.

Culture alternatives

This has prompted scientists and the oyster industry to determine ways to combat these issues through alternative culture techniques, programs and research. One possible solution would be culturing oysters in a closed system, isolated from environmental risks. However, there could be drawbacks, such as cost and potential risks associated with dense monoculture.

Even if production of oysters in closed systems is not realistic in terms of producing oysters intended for food, understanding of how to culture oysters in these systems could offer an opportunity for more toxicological research and feeding studies. This technology could also be useful for breeding and genetic programs.

Oyster RAS

In a study, the authors evaluated whether oysters could be cultured in a recirculating aquaculture system (RAS) with zero water exchange for several months. The study objectives were to manage suitable water quality parameters, monitor mortality rates and track growth.

The 12-week growout study was conducted in a closed-loop recirculating system with zero discharge using synthetic seawater made from well water and synthetic sea salt. Approximately 7,000 oysters were stocked in a single layer in four, 1.83-meter diameter tanks. The tanks were each partially filled with 3,200 L of water.

This culture system was outfitted with various filtration technologies and connected to a 4,000-L storage tank and 12, 1,000-L algae culture tanks. Two species of marine microalgae were grown as oyster feed: a Chaetoceros species diatom and a dinoflagellate, Isochrysis species.

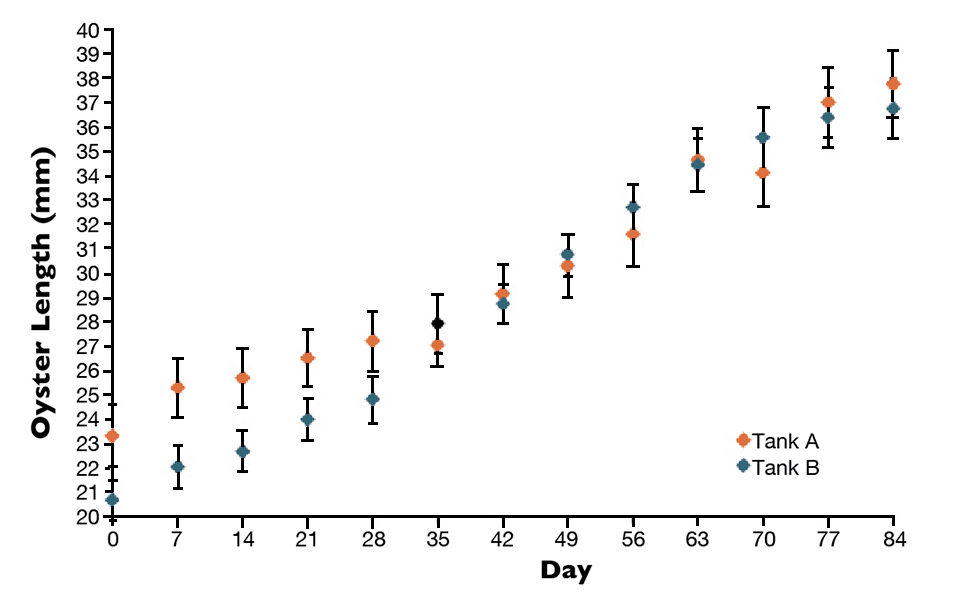

The oysters were batch fed daily. The amounts of algae cells offered exceeded 300 million cells/oyster, which is the estimated amount an adult oyster can filter in a day. Ion chemistry was monitored and supplemented as required to maintain suitable water conditions. Oyster growth was monitored on a weekly basis.

Water quality parameters were within desired ranges for oyster culture. Observed mean concentrations of ammonia, nitrite and nitrate were all less than 1 percent of the lethal concentrations reported in scientific literature. Approximately 95 percent of oyster shells is calcium, so the animals have a high demand for calcium to grow. Accordingly, calcium was supplemented in the culture environment.

Results

The two species of marine microalgae used in this study were selected because the blend has been demonstrated by others as an appropriate choice for bivalve culture. Survival rates for the study exceeded 99 percent, and the oysters grew an average 1.3 mm/week. Mean oyster mass increased an average of 0.39 grams weekly.

The weekly growth in length was comparable to, and in some cases higher than, published growth data for oysters of similar initial size deployed in the field. Oysters in the ocean and bays typically grow 0.38-2.50 mm/week.

Factors that influence growth include the amount of feed in natural waters and temperature. Both factors can not be controlled in the natural environment, but can be controlled in recirculating aquaculture systems. Therefore, oysters grown in closed systems could offer distinct advantages over wild counterparts because high water temperatures could be implemented year round.

Perspectives

The good survival and growth of oysters in this closed system demonstrated that oysters can be potentially cultured in recirculating systems using synthetically derived seawater and live feeds. However there may be some potential issues to consider.

Concentrations of organics and potentially toxic waste products can negatively affect the growth of these organisms or pose a health concern for oysters intended to be consumed raw and unprocessed. While most recirculation systems allow for high stocking densities, the close proximity of animals could also allow the rapid magnification and dispersal of some infection agents.

Future studies are needed to investigate a longer culture period, alternative feeds and the safety and quality of oysters before oysters raised in closed systems can be considered for human consumption. However, this information can be useful today for those interested in culturing oysters for controlled studies, genetic and breeding programs. Other bivalves, such as clams, mussels and scallops, could also possibly be considered as candidates for culture using land-based recirculating systems.

(Editor’s Note: This article was originally published in the May/June 2013 print edition of the Global Aquaculture Advocate.)

Authors

-

David D. Kuhn, Ph.D.

Department of Food Science and Technology

Virginia Tech

Blacksburg, Virginia 24061 USA -

Matt A. Angier

Department of Food Science and Technology

Virginia Tech

Blacksburg, Virginia 24061 USA -

Stephen A. Smith, DVM, Ph.D.

Department of Biomedical Sciences and Pathobiology

Virginia-Maryland Regional College of Veterinary Medicine

Virginia Tech

Blacksburg, Virginia 24061 USA -

Sandra Barbour

Blue Ridge Aquaculture, Inc.

Martinsville, Virginia, USA

Tagged With

Related Posts

Responsibility

Ailing waterways hail the oyster’s return

The Lower Hudson Estuary and Chesapeake Bay, two waterways once home to thriving oyster beds, would welcome the shellfish’s return. Aquaculture initiatives in both areas aim to reinvigorate the water and the communities they support.

Health & Welfare

Artificial upwelling maintains favorable summer environment for farmed oysters

The summer season poses threats for oyster aquaculture worldwide. In addition to high mortality, poor oyster quality and health – especially in enclosed bays – are often attributed to water stratification, high temperatures and hypoxia.

Intelligence

Behold the nutritious oyster

Oysters provide important, natural filtration of water and are an important component of many healthy coastal ecosystems because their active filtering can help improve and maintain water quality. For many coastal communities, oysters are an important food resource and excellent sources of protein and amino acids, zinc, selenium, iron and B-vitamins.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.