Novozymes Biologicals’ bacteria product is rich in both types of nitrifiers needed to convert ammonia into nitrate

Nitrogenous wastes can accumulate in closed aquaculture ponds and recirculating systems, primarily in the forms of ammonia from animal excretion and decomposing organic solids such as uneaten feed.

Ammonia can be removed from the systems and used directly as a nutrient by heterotrophic bacteria, algae or plants. Ammonia can also be removed from the system via nitrification, which is a two-step process performed by autotrophic bacteria called nitrifiers.

More specifically, oxidation of ammonia to nitrite is typically performed by bacteria from the genus Nitrosomonas. Nitrite is then oxidized to nitrate by bacteria from the genus Nitrobacter. The nitrification process often takes place naturally in ponds and recirculating system biofilters.

It is important to ensure nitrification is efficient in the conversion of ammonia and nitrite to nitrate because nitrate is the least toxic form. Ammonia and nitrite are toxic to aquatic animals at concentrations as low as 1 mg/L. Meanwhile, nitrate doesn’t become toxic to aquatic animals until concentrations are greater than 60 mg/L. Some aquatic animals are more sensitive, while others exhibit greater tolerance to these nitrogenous wastes.

Effective nitrification

Factors that influence nitrification efficiencies include the amount of nitrogenous waste, nitrifier population and types, biofilm thickness, alkalinity, oxygen levels and temperature. If healthy populations of both ammonia- and nitrite-oxidizing bacteria are not present, then no nitrification will occur.

This is the case for a new biofilter that has no bacteria. It typically takes four to eight weeks to initiate a new biofilter using earlier techniques, which prescribe no additions other than ammonia. Furthermore, sometimes a biofilter that is established can fail and needs to be restarted. In both cases, a bacterial product that is rich in both ammonia- and nitrite-oxidizing bacteria could provide the means to mitigate ammonia and nitrite.

Nitrifier product

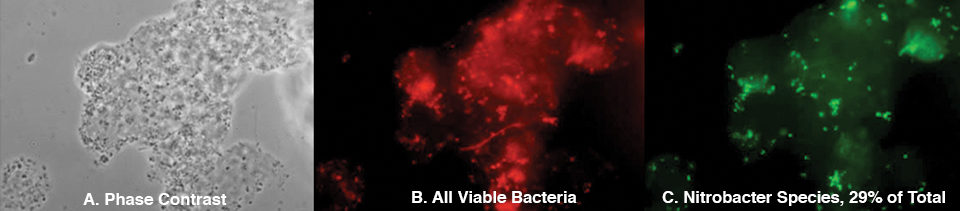

Novozymes Biologicals, Inc., a biotech company based in Salem, Virginia, USA, has developed a nitrifying bacteria product that is rich in both types of nitrifiers needed to convert ammonia into nitrate. This liquid product, PondProtect-L, is primarily a combination of Nitrosomonas eutropha ammonia-oxidizing bacteria and Nitrobacter winogradskyi nitrite-oxidizing bacteria, both of which are great candidates for typical aquaculture waters.

Novozymes teamed with Virginia Tech to conduct research on the effectiveness of this product in a controlled bench-scale study and on a production scale at a shrimp farm in Virginia. In both cases, recirculating aquaculture systems (RAS) were tested with white shrimp, Litopenaeus vannamei, at salinities ranging approximately 10-15 g/L.

Bench study

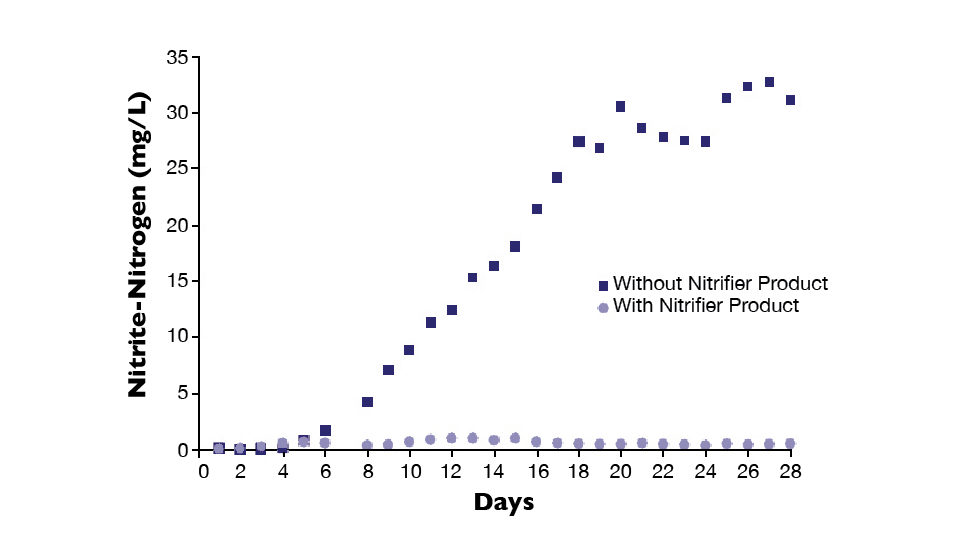

The bench-scale study was conducted in six 150-L recirculating systems with a new biofilter. Three systems were inoculated with the bacteria product and three systems did not receive any bacteria. Thirty juvenile shrimp were stocked in each system and fed the same type and amounts of food. Nitrification rates in the inoculated systems had significantly lower levels of both ammonia and nitrite (Fig. 1).

Quantitative polymerase chain reaction testing was used to verify the presence of the desirable Nitrobacter winogradskyi nitrifying bacteria strain in the inoculated systems.

Production-scale application

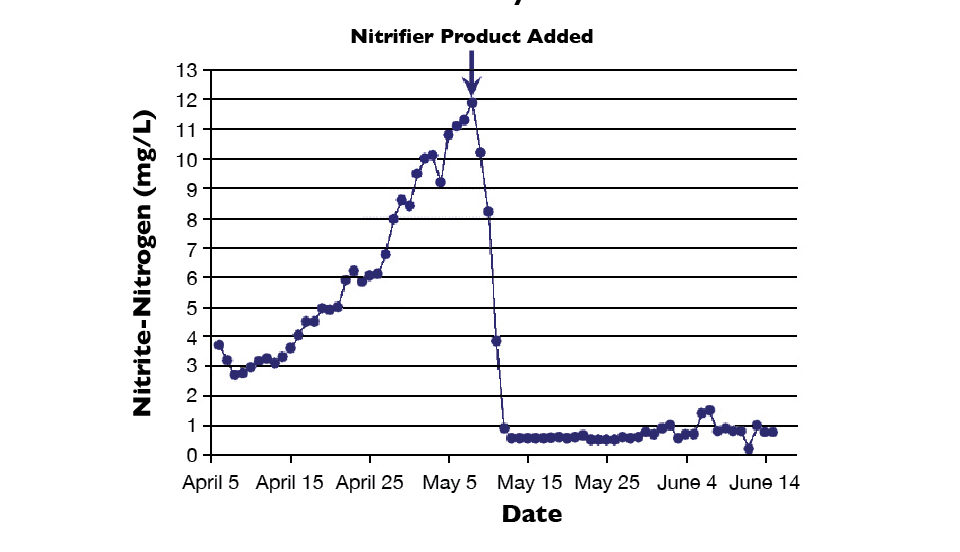

During the first year of operation, a commercial-scale RAS shrimp farm observed occasional spikes of ammonia and long-sustained spikes of nitrite, which significantly impaired the health of shrimp in the production-scale raceways.

To mitigate these pollutants from compromising shrimp production, the nitrifying bacteria product was applied to the systems. Shortly after application, nitrite levels began to decrease significantly and continued to drop to levels considered safe for shrimp culture (Fig. 2).

Perspectives

Many aquaculture operations rely on nitrification for the removal of toxic nitrogenous constituents such as ammonia and nitrite from the culture water. This process relies on a healthy population of nitrifying bacteria.

The use of a commercial nitrifying product can inoculate a new biofilter or a failing biofilter with viable populations of both ammonia- and nitrite-oxidizing strains of bacteria. Even though the nitrifying bacteria product tested was initially designed for pond applications, it performed well in recirculating systems.

(Editor’s Note: This article was originally published in the July/August 2011 print edition of the Global Aquaculture Advocate.)

Authors

-

David D. Kuhn, Ph.D.

Department of Food Science and Technology

Virginia Tech

Blacksburg, Virginia, USA -

David J. Drahos

Senior R & D Group Leader

Novozymes Biologicals, Inc.

Salem, Virginia, USA

Related Posts

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Innovation & Investment

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.

Health & Welfare

Ammonia addition enhances microbial flocs in nursery phase for Pacific white shrimp

In a study, “pre-fertilization” in the nursery phase of a biofloc system for shrimp was tested. The objective was to accelerate the biofloc formation to minimize ammonia concentrations, avoiding high peaks during culture.

Aquafeeds

Aquaculture feed composition helps define potential for water pollution

A study found that feed for salmon and trout had higher organic carbon concentrations than did catfish, shrimp and tilapia feeds. Nitrogen and phosphorus concentrations were similar among salmon, trout and shrimp feeds, and higher than those in catfish and tilapia feeds.