Results show no clear correlation between feed ingredients and growth, feed consumption or feed demand

Limited availability and relative high cost of fishmeal are the main drivers of research to identify and test least costly, more sustainable protein sources for feeds. Particularly for species cultured on a global scale with tremendous economic interest such as shrimp. It is not surprising that for the last decade the shrimp feed industry has mostly moved towards integrating less expensive protein sources from plants (e.g., soybean and corn byproducts) and terrestrial animal by-products (e.g., poultry byproduct, meat and bone, and blood meal). These diets have been proven adequate to support shrimp growth in various production systems, densities and regions by both academic research and the industry. Nevertheless, many farmers are still skeptical that shrimp will consume feeds with low to no inclusion of fishmeal.

Animal nutrition research has various mechanisms of measuring feed intake under laboratory conditions. However, this can be very challenging in a shrimp production context, as systems usually use very turbid water and animals are stocked at high densities, particularly in outdoor ponds. Using passive acoustic techniques, the consumption of feed can be heard, allowing real-time monitoring under field conditions. This technology has been tied to automated feeding systems resulting in on-demand passive acoustic feeding systems.

These systems have become increasingly common and proven to be one of the most efficient feeding technologies available. It captures the sound produced by the shrimps’ feeding activity to self-manage feed dispersion. Therefore, it is possible to use these feeders to let shrimp self-regulate their food inputs, adjusting their feed intake based on preference. The objective of this study was to use on-demand passive acoustic feeders as a tool to evaluate shrimp feed demand and response to commercial feeds with different protein sources.

Study setup

This study was performed at the Alabama Department of Conservation and Natural Resources, Claude Peteet Mariculture Center, Gulf Shores, Alabama (USA). Pacific white shrimp (Litopenaeus vannamei) larvae were obtained from American Penaeid (Fort Myers, Fla., USA), acclimated and nursed in a greenhouse system. Juvenile shrimp were then stocked into 16 outdoor, 0.1-hectare (ha) ponds at 30 shrimp per square meter. The ponds were harvested 90 days after stocking.

Every pond was equipped with a commercial AQ1 system (Fig. 1), which consisted of a centrifugal feeder to disperse feed, a hydrophone to capture underwater acoustic response and a dissolved oxygen sensor, all connected to a main controller on the levee with wireless connection to an office. Each pond was fed ad libitum to a maximum of 160 kg/ha/day to avoid oxygen depletion and oxygen sensors were set to initiate mechanical aeration when readings were below 3 mg per liter. While each feeder was calibrated before the initiation of the system, some feeders had to be re-calibrated within the first three weeks of utilization, allowing feeding up to 210 kg/ha/day.

For the first 17 days, all ponds were hand-fed a predetermined amount of the same 1.5-mm commercial diet (40 percent crude protein, 9 percent crude lipids) produced by Zeigler Bros. Inc. (ZBI, Gardners, Pa., USA). After that period, feeders were used and diets were changed to four 2.4-mm commercial diets (35 percent protein, 8 percent lipids) with different ingredients as protein sources: all plant; 8 percent poultry meal (8 percent PM); 8 percent fishmeal (8 percent FM); and 12 percent fishmeal (12 percent FM) (Table 1). The acoustic feeding began on day 44.

Reis, acoustic feeders, Table 1

| Ingredient | All plant | 8% PM | 8% FM | 12% FM |

|---|

Ingredient | All plant | 8% PM | 8% FM | 12% FM |

|---|---|---|---|---|

| Soybean meal: 47.5 | 560.0 | 500.0 | 537.0 | 575.0 |

| Wheat | 191.0 | 231.0 | 219.0 | 216.0 |

| Menhaden 62% spec. select | 0.0 | 0.0 | 80.0 | 120.0 |

| Poultry byproduct meal: 67 | 0.0 | 80.0 | 0.0 | 0.0 |

| Corn gluten 60% | 120.0 | 80.0 | 60.0 | 0.0 |

| Dicalcium phosphate | 41.3 | 31.3 | 26.3 | 16.3 |

| Other components* | 87.7 | 77.7 | 77.7 | 72.7 |

*Other components include fish oil, vitamin and mineral premixes and other trace ingredients.

Shrimp were sampled weekly through the entire production stage using a cast net (1.52 meters radius; 0.96 cm mesh) to collect approximately 60 individuals per pond. Pond sampling enabled growth assessment and inspection for general health. Ponds were monitored (dissolved oxygen, DO; temperature; salinity; and pH) at least three times a day, at sunrise (5 to 5:30 a.m.), afternoon (2 to 2:30 p.m.) and sunset (7 to 8 p.m.). All ponds had one 2-hp Aire-O2 (Aire-O2, Aeration Industries International, Inc., Minneapolis, Minn., USA) as a main source of mechanical aeration, which was self-managed through the oxygen sensor, and one 1-hp Air-O-Lator (Kansas City, Mo., USA) for backup and/or supplemental aeration as needed.

Results and discussion

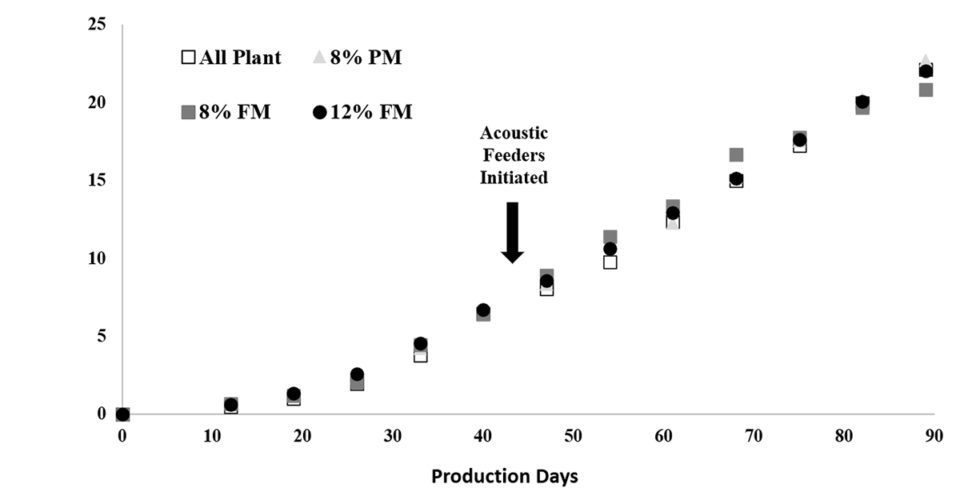

Growth rates (grams per week) throughout the trial are presented in Fig. 2. Regardless of the diets used during the cycle, all ponds achieved commercial size shrimp within the culture period. Considering the growth parameters we measured, we were not able to establish a direct connection between any diet and final average size of individuals. Although we did observe some differences in average individual size on days 54 and 68, we believe these are more likely related to the characteristics of the sample itself or the stage of the ponds’ natural cycles (i.e. natural productivity crash) than to the production diets used.

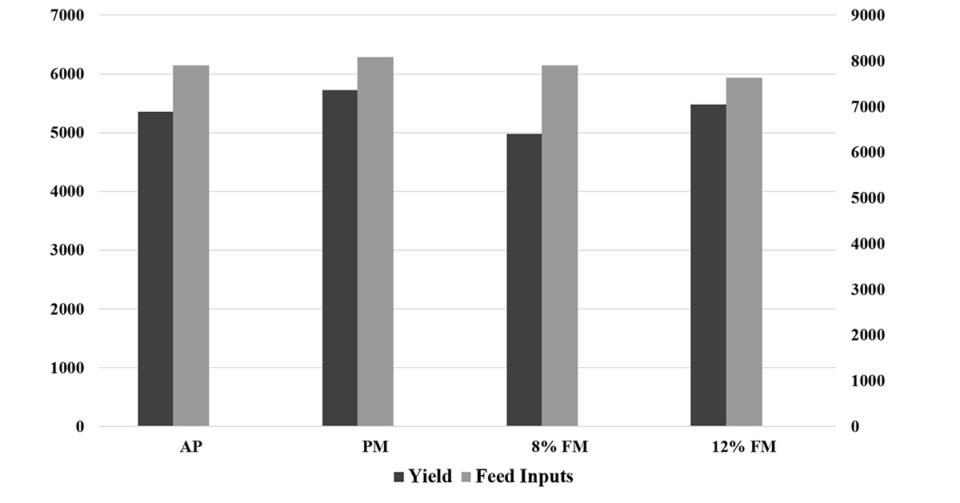

Average final yields and total feed inputs for each treatment are presented in Fig. 3. We did not observe any clear differences in feed inputs, which leads us to believe that when shrimp were fed ad libitum there was not a preference for a specific protein source. We observed lower average yields for the treatment being feed the 8 percent fishmeal diet which was not surprising considering the lower average individual weight on the last sampling before harvest. Overall feed conversion rates, FCR, varied from 1.21 to 1.48, very much comparable to the majority of the industry’s outdoor shrimp production systems.

As the results presented here do not show any clear correlation between ingredients in the feed and growth performance, feed consumption or feed demand, we believe this is another important contribution on the role that alternative protein ingredients have in aquaculture in general and shrimp aquaculture in particular. It seems clear that when farmers using acoustic systems are presented with various options for well-balanced formulated feeds, they can confidently choose based on sustainability and price rather than on unfounded perceptions of what ingredients shrimp may or may not naturally prefer.

Perspectives

Our study results show that currently available commercial feeds are adequate to achieve acceptable shrimp growth in outdoor production conditions regardless of the protein source. As we continue to learn more about acoustic patterns and very efficient acoustic feeding systems become an increasingly common reality in shrimp pond production, we expect that feed companies will increase optimizing their products for this technology. Specifically, in the context of physical properties of pellets (i.e. size, hardness, etc.) as well as the inclusion of different attractants that might further improve feed management through quicker consumption of the diet.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

João Reis, M.S.

Corresponding author and Ph.D. student

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn, Alabama 36849-5419 USA -

Alexis Weldon

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn, Alabama 36849-5419 USA -

Samuel Walsh

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn, Alabama 36849-5419 USA -

William Stites

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn, Alabama 36849-5419 USA -

Melanie Rhodes, M.S.

Research Associate

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn, Alabama 36849-5419 USA -

D. Allen Davis, Ph.D.

Alumni Professor

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

Auburn, Alabama 36849-5419 USA

Tagged With

Related Posts

Innovation & Investment

Acoustic control improves feeding productivity at shrimp farms

In systems recently developed for shrimp farms, passive acoustic-based technology enables sensor-based control of multiple automatic feeders. Improved growth and feed conversion have been recorded at commercial farms using the technology.

Aquafeeds

Acoustic feedback improves automated feeding systems for shrimp

Updating Auburn University’s standard feeding protocol for shrimp into an optimized version for timer-feeders, recognizing the role of acoustic feedback.

Innovation & Investment

Fish behavior-tracking tech aims to curb aquafeed wastage

Overfeeding is a waste stream for aquaculture. Underwater cameras in pens help, but a company mixing hydroacoustics and machine learning has another idea.

Responsibility

Precision fish farming: A new framework to improve aquaculture, Part 1

A review of technology usage in finfish aquaculture, future application possibilities for precision fish farming (PFF) and guidelines for research.