Strategy for future development should include enhanced safety measures

The cultured shrimp sector is one of the most profitable in the global aquaculture industry. In 2014, farmed shrimp – at $23.58 billion – was the second-most valuable product after carps, and the Pacific white shrimp (Litopenaeus vannamei) was the most valuable farmed species by value at $18.46 billion (FAO).

Despite its global importance, the shrimp farming industry has suffered a number of important disease outbreaks that have caused significant economic losses over the last several years. Other land-based, meat-producing industries have developed in the same manner, so the shrimp farming sector can benefit from their learning curves regarding the development and implementation of biosecurity protocols as it continues to expand global shrimp production.

Per the United Nations’ Food and Agriculture Organization, biosecurity is defined as “the implementation of measures that reduce the risk of disease agents being introduced and spread. It requires that people adopt a set of attitudes and behaviors to reduce risk in all activities involving domestic, captive/exotic and wild animals and their products.”

The use of formulated shrimp aquafeeds is an important component of and a significant reason why the shrimp farming industry has developed so successfully and essentially quadrupled global production in the last three decades. It is imperative that shrimp feeds are not an entry point of potential pathogens to the shrimp and/or to their culture systems.

Biosecure shrimp feeds and on-farm feeding strategies involve all aquafeeds (live, fresh or formulated) and their management at every component of the shrimp production value-chain. This article summarizes the original publication (Journal of the World Aquaculture Society – doi: 10.1111/jwas.12406).

Shrimp aquafeeds and biosecurity risks

Shrimp producers for the most part understand the biosecurity risks related to the moving of live shrimp – including broodstock and larval stages – across national borders and between different regions, but the biosecurity concerns associated with shrimp feeds and their management in each of the production components, including broodstock operations, larval rearing, nurseries and grow-out, are generally not as well understood.

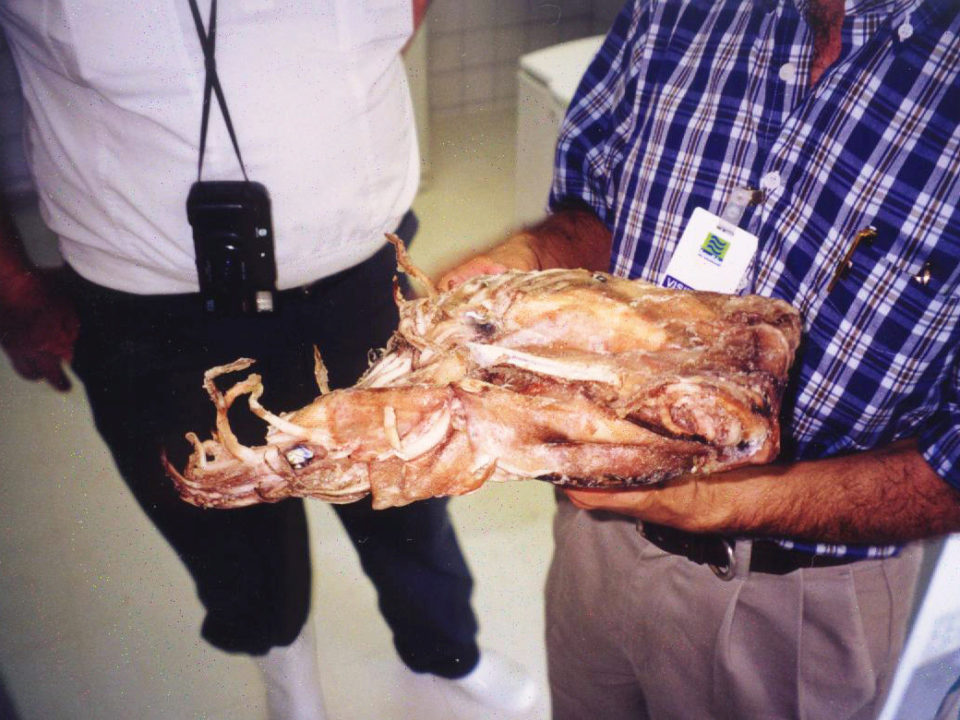

Globally, shrimp farmers use a variety of production systems and a several types of feeds, including wild-caught or cultured, live and/or processed natural food organisms (including artemia nauplii and biomass, oysters, mussels, marine polychaetes, squid, crabs and pelagic shrimp, microbial biomass or biofloc, supplementary farm-made feeds, and commercially formulated and manufactured extruded or pelleted diets).

Of particular concern is the use of live and fresh unprocessed feed items, including live bivalves and polychaetes, unprocessed squid and contaminated artemia, that are commonly used globally at various stages of the shrimp culture cycle, generally in broodstock maintenance and conditioning, and in some cases larval rearing and even grow-out.

There is evidence and growing concern that several of these items could also be a biosecurity risk by introducing potential viable pathogens into the shrimp culture facilities. Some of these pathogens include White Spot Syndrome Virus (WSSV), Hypodermal Hematopoietic Necrosis Baculovirus; Infectious Hypodermal and Hematopoietic Necrosis Virus (IHHNV); bacteria, Acute Hepatopancreatic Necrosis Disease (AHPND); and microsporidean parasites.

Another risk there is the use of raw and/or inadequately processed, contaminated shrimp sub-products (like shrimp head meal or shrimp meal) in grow-out, and/or through the top-dressing of commercial pelleted shrimp feeds by the farmer prior to feeding and using contaminated shrimp or fishery products.

Reportedly, pathogens such as WSSV that may be present in contaminated ingredients (like shrimp head meal) are promptly destroyed during conventional feed pellet manufacturing.

But more heat-resistant parasites and bacterial pathogens may not be destroyed by the pelleting process, compared to extrusion feed manufacturing processing that uses higher cooking temperatures and the feed pellets are typically completely pasteurized.

Considering the disease risks mentioned above, commercial shrimp aquafeed manufacturers should consider the formulation and production of a new generation of bio-secure, separate and nutritionally complete aquafeeds encompassing the entire shrimp production cycle, from the first feeding larval stage to broodstock maturation. All nutrients and naturally occurring substance (like hormones, enzymes, pigments, polysaccharides, pigments, organic acids and others) can be incorporated into fully bio-secure, commercial shrimp feeds, including those for larval and nursery rearing.

Involvement of stakeholders

All stakeholders, including governments, shrimp aquafeed manufacturers, sellers and brokers, farmers and others, should be involved to make sure that shrimp feeds and their management at production facilities are biosecure.

Government authorities responsible for the aquaculture industries in their countries should produce legislation that ensures that shrimp aquafeeds are formulated for optimal animal well-being and health, and fully disclosing ingredients and nutrient levels; for these feeds to be certified as biosecure and free of pathogens; to prohibit the importation of food items (like some live feeds and others) that cannot be certified as pathogen-free, the recycling of intra-species sub-products, and the top dressing of feeds with unregulated additives; to provide training to farmers on biosecure aquafarming practices; and to prosecute illegal additives including banned antibiotics.

Shrimp feed manufacturing companies should produce properly formulated and complete aquafeeds that promote optimal animal well-being and health; fully disclosing ingredients and nutrient levels used and ensuring their products are biosecure and free of pathogens; encourage farmers to not top-dress their feeds on farm with illegal feed additives; and promote and provide training for the use of adequate, on-farm feed management practices.

Aquafeed manufacturers should also be aware of existing, internationally accepted aquaculture feed regulations concerning the prohibition of intra-species recycling (that is, the feeding of the same or closely related species back to the same cultured species) for biosecurity concerns, including the FAO Good Aquaculture Feed Manufacturing Practices, the Global Aquaculture Alliance (GAA) Best Aquaculture Practices (BAP) Standards and Guidelines for Finfish, Crustacean and Mollusk Hatcheries and Nurseries, and BAP Standards and Guidelines for Feed Mills.

Shrimp aquafeed brokers and traders should provide local authorities and shrimp producer associations with records, on a regular basis, of the feed additives sold to farmers in their sales area; and they should not be involved in the selling of illegal additives like banned antibiotics, or adulterated or expired aquafeed ingredients.

Shrimp farmers must strive to maintain their animals at optimal water quality conditions, including dissolved oxygen levels > 4mg/L and water temperatures ~ 28 to 30 degrees-C, and to try to apply feed frequently in small portions and to prevent overfeeding and pond water and bottom deterioration; they must be aware of the value and relevance of proper record-keeping to track and monitoring aquafeed usage, and calculating feed efficiency; if top-dressing, using only approved additives and avoid the use of fresh feeds; use antibiotics only under veterinary supervision; expedite the proper disposal of dead shrimp and molts using biosecure methods; and in general implement appropriate farm and fed management procedures.

Perspectives

A number of major shrimp diseases continue causing significant economic losses, and shrimp aquafeeds – live, fresh, or formulated, and their farm management – should not be an entry point of potential pathogens to the shrimp and/or to their culture facilities. It is very important that all stakeholders, including governments, shrimp aquafeed manufacturers, sellers and brokers, farmers and others, are involved to make ensure that shrimp aquafeeds and their management at production facilities are biosecure.

To exclude pathogens from their current outdoor pond production systems, the shrimp industry can follow the strict, indoor, environmentally-controlled and biosecure production systems used by the modern intensive livestock production systems. This will allow for better control of the environmental rearing conditions and optimized water quality, and for reduction of stress and disease susceptibility of the cultured shrimp.

Finally, it is relevant to point out that shrimp require about 40 essential nutrients in their diets for optimal growth, health and well-being. Aquafeed companies must consider this and formulate their products using higher dietary nutrient levels (for specific essential amino acids, fatty acids, sterols, minerals, and vitamins). Additionally, other feed additives should also be included to promote shrimp health and possibly disease resistance, including specific marine and microbial polysaccharides, nucleotides, organic acids, essential oils, prebiotics, and various helpful probiotics.

References available from author.

Author

-

Albert G.J. Tacon, Ph.D.

Aquatic Farms, Ltd.

49-139 Kamehameha Highway

Kaneohe, Hawaii 96744 USA