Sedimentation and biofiltration simple but effective technologies that should be widely adopted by industry

The proper operation and viability of shrimp hatcheries depend on the availability of a continuous source of clean water, and proper treatment of their effluents before discharge to the surrounding environment, particularly in areas where several hatcheries may coexist.

In terms of quality and quantity, water discharges from shrimp hatcheries are very different from those of shrimp farms. Farm effluent is characterized by a high biological oxygen demand (BOD) and high dissolved organic matter (DOM) but the risk of potential pathogens generally is relatively low. The opposite is the case in shrimp hatcheries, with low levels of organic matter and total bacteria but a relatively high load of potential pathogens.

Therefore, the method and objective of wastewater treatment depends on the type of operation. In the case of hatcheries, the objective is to minimize the discharge of potential pathogens and reduce the total bacterial load, although most of the wastewater treatment systems have components dedicated to both purposes. This article – adapted and summarized from the original publication in Revista Acuacultura: Cámara Nacional de Acuacultura, No. 122, April 2018) – discusses some practical approaches that can be implemented in shrimp hatcheries.

Sedimentation

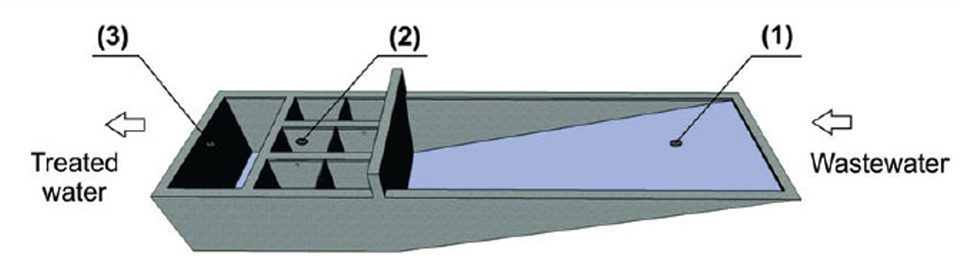

The use of sedimentation ponds is one of the simplest methods for reducing the load of suspended solids (SS) of hatchery effluents. The basic principle involves providing sufficient time for the sedimentation of the organic matter particles suspended in the effluent’s water column – which are typically composed of unconsumed feed, feces and flocs of algae and bacteria – before discharging it to the surrounding environment. It separates the higher density material by sedimentation, and the lower density materials by flotation and then by draining the water surface.

Often, there are other processes – such as aeration and protein skimming – also used before the final discharge, if it is necessary to further reduce the BOD. Protein skimmers are used to remove organic compounds like food and metabolic waste from water, and their use is very common in municipal wastewater treatment plants.

Sedimentation basins could be the most appropriate technology for the treatment of water discharges from hatcheries, due to their low energy demand, simplicity of construction and little operational requirements. However, they have substantial space requirements, which may be the limiting factor for its use in some existing hatcheries.

The efficiency of sedimentation depends on the design, surface area and the residence time of the effluent. The purification capacity decreases with very small, friable (easily pulverized or crumbled) particles and with similar medium densities; in other words, it works better with large, hard and heavy particles. This system cannot remove dissolved materials and colloids in suspension (lipids), although their separation can be done by centrifugation using swirl chambers, but the benefit vs. cost of centrifugation would appear to make it difficult to justify in most hatcheries.

Sedimentation can be an excellent solution as long as the hatchery has enough area to build and operate sedimentation ponds with adequate dimensions for the separation of suspended solids typical of shrimp hatcheries.

Biofiltration

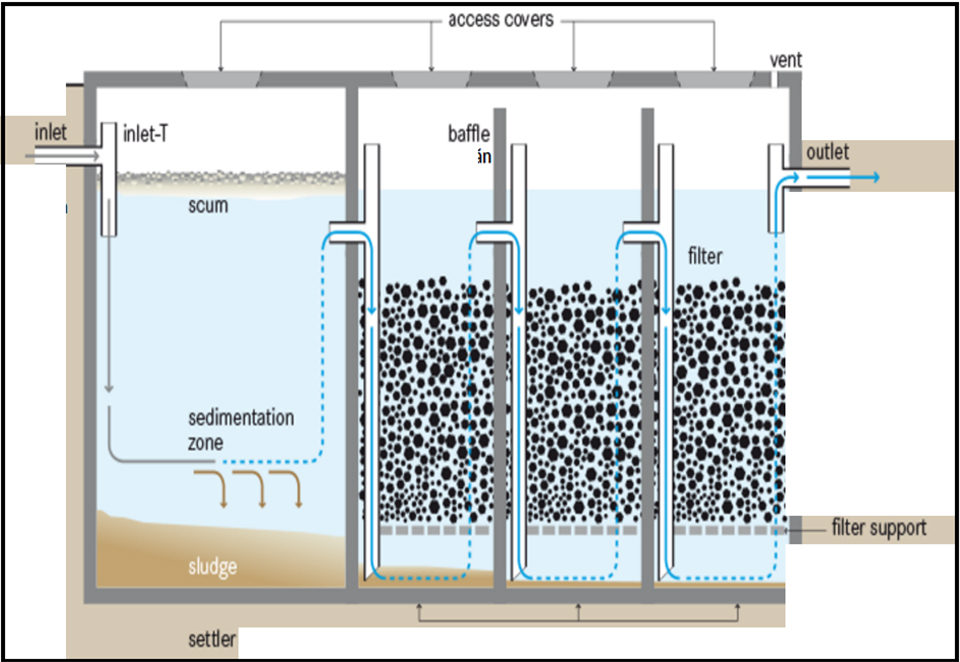

Biofiltration is an example of a technology which, although very simple, is very efficient in the remediation of wastewater, as shown in its widespread use in municipal water treatment systems. Its basic principle is the use of heterotrophic bacteria to reduce the organic load and detoxify the metabolites in the wastewater. A biological filter generally consists of a large surface area for the attachment of bacteria and means to increase dissolved oxygen levels to meet the biological demand of the filter. The heterotrophic bacteria convert organic matter to cytoplasm and the metabolites are volatilized as carbon dioxide (CO2) and ammonia (NH3), or fixed as protein.

A biological filter works with a wide range of bacteria, but there are two groups whose functions are vital for the remediation of water. Nitrosomonas spp. and Nitrobacter spp. work together to convert nitrite to nitrate and then volatilize nitrogen in the form of free NH3. Thus, a biological filter represents a refined and economical solution for the detoxification of the biological waste and a way to reduce the load of dissolved organic matter that cannot be eliminated by means of sedimentation ponds. For this reason, most treatment plants also have biological filtration beds after the sedimentation ponds.

The handling of filtration capacity is very important when considering that the organic matter load can be highly variable with wastewater from hatcheries that operate by complete stocking and harvesting (“all in, all out”). A biostatic system with stable biomass would be optimal in terms of ease of management; however, the practical implications of such a system will probably be too complicated to justify its consideration for hatcheries.

Biofiltration has many advantages, including relative low cost, non-use of contaminants and generally high efficiency, but its operation requires technical knowledge of the dynamics between bacterial populations and the source of nutrients to obtain the best results.

Other technologies

Effluent water can also be disinfected using advanced oxidation technologies such as the application of ozone or ultraviolet light, but the costs currently associated with these technologies and the problem of rapid bacterial repopulation after discharge mean that there may not be practical at this time. Given this, in the case of a collective wastewater treatment station from a production area (not just one hatchery), ozone could be a very effective way of ensuring that there will be no possibility of re-contamination of the same pathogens that can grow in the hatcheries.

Perspectives

A practical, comprehensive and effective plan is required for the treatment of shrimp hatchery effluents. The implementation of technologies for treatment of these wastewaters is not only often a legal requirement, but also an essential element for the sustainable growth of the shrimp industry.

A land-use plan should be used as a guide, and it should have clear information on the design, dimensions, installation and operation of the wastewater treatment systems. For all future investments in shrimp hatcheries, the site selection and the operation design must include all the technical aspects of wastewater management. As with other regulations, it is always preferable if the initiative and its management comes directly from the sector itself and not from outside.

References available from author.

Author

-

Philip Buike

Technical Manager

National Aquaculture Chamber (Cámara Nacional de Acuacultura)

Guayaquil, Ecuador

Tagged With

Related Posts

Responsibility

Advances in super-intensive, zero-exchange shrimp raceways

Research at the Texas AgriLife Research Mariculture Laboratory is investigating ways to improve the economic viability of super-intensive raceways for shrimp production.

Aquafeeds

Crude protein and lipid from biofloc meals from an activated sludge system

A study compared the bioavailability of crude protein and lipid from biofloc meals generated with an activated sludge system using two water sources: wastewater from shrimp experimental culture (BFL-W) and, artificially, using clean seawater (BFL-C).

Innovation & Investment

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.

Responsibility

For the future, a feed that makes fish feces float?

German researcher believes that floating fish feces – stemming from cork used in feed blends – would help recirculating aquaculture systems more efficiently remove suspended solids. The big question is, will feed manufacturers get on board?